Transporting vehicle goods translation device

A technology for handling vehicles and translation devices, applied in the direction of lifting devices, etc., can solve the problems of occupying the payload of forklifts, heavy sliding tables, slow movements, etc., to reduce labor intensity, avoid repeated shifting operations, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

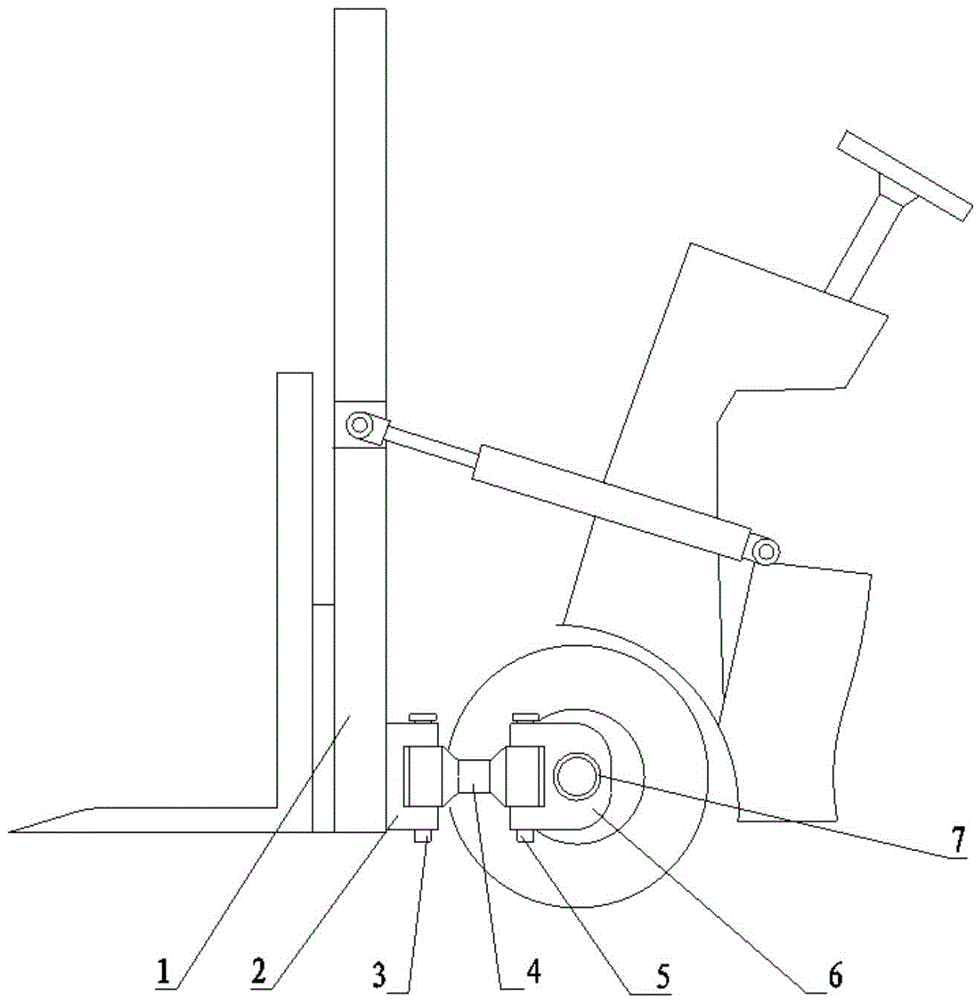

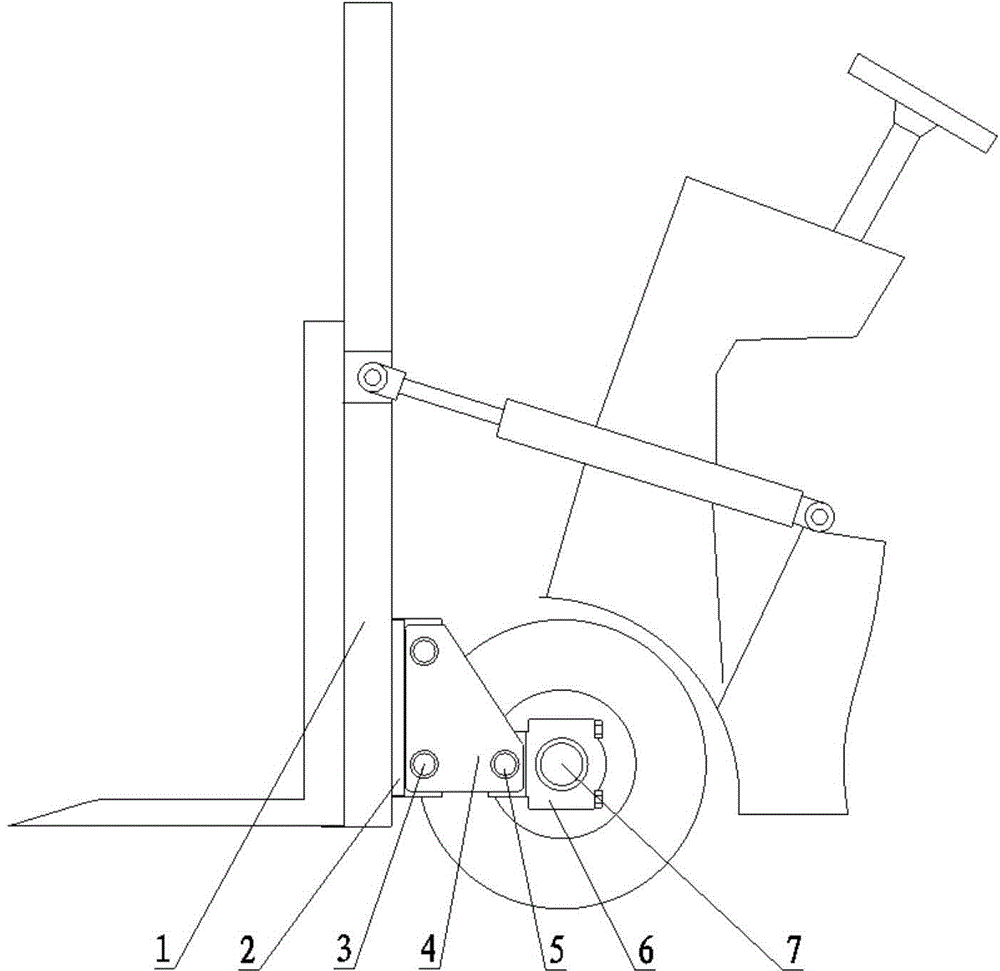

[0019] Such as figure 1 , figure 2 As shown, one end of a group of swing arms 4 is hinged on the mounting base 6 through the hinge shaft 5, the mounting base 6 is hinged with the forklift front axle axle sleeve 7, and the other end of the swing arm 4 is hinged on the support 2 through the hinge shaft 3. Above, the support 2 is fixedly connected with the forklift mast 1; one of the two ends of the power unit 8 is hinged on the vehicle body, and the other end is hinged on the forklift mast 1; the control device on the power unit 8 is installed in the cab.

[0020] The working principle of the cargo translation device is that when the control device is operated, the power unit 8 generates an action to push or pull the forklift mast 1 to move. Due to the parallelogram structure of the swing arm, the movement of the mast 1 is always parallel to the original position. That is, when the mast moves in translation, the attachments carried on it move in translation, and the direction ...

Embodiment 2

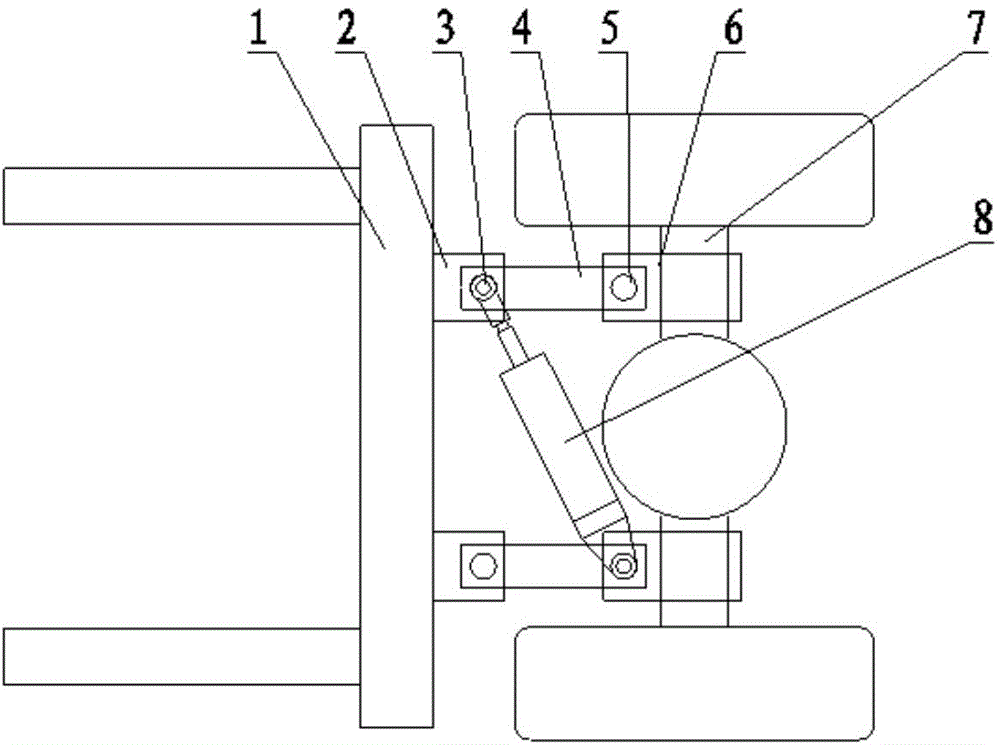

[0023] Such as image 3 , Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the connection between the mounting seat 6 and the forklift front axle axle sleeve 7 is fixed, and the connection between the swing arm 4 and the support 2 and the mounting seat 6 has Joint bearing 9, the axial direction of joint bearing shaft 3 and 5 is horizontal, to realize the free movement of gantry pitching and translation.

Embodiment 3

[0025] Such as Figure 5 , Figure 6 As shown, one end of a group of swing arms 4 is hinged on the support 11 through the pin shaft 5, and the support 11 is fixedly connected with the forklift door frame 1, and the other end of the swing arm 4 is hinged on the support 2 through the pin shaft 3, and the support The seat 2 is fixedly connected to the attachment 10; one of the two ends of the power unit 8 is hinged on the forklift mast 1, and the other end is hinged on the attachment 10; the control device on the power unit 8 is installed in the cab.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com