Emulsion pump capable of preventing opening and leakage in transportation process

A lotion pump and waterproof ring technology, applied in the field of lotion pumps, can solve problems such as separation and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

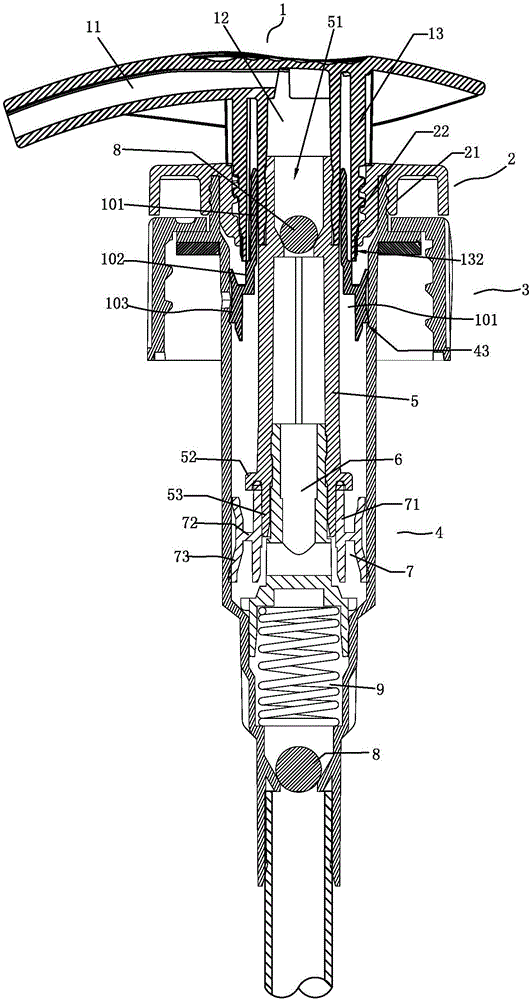

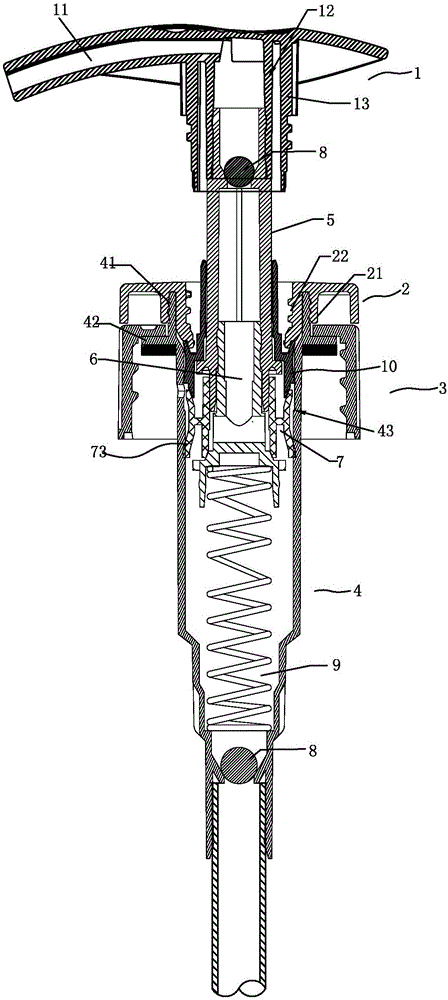

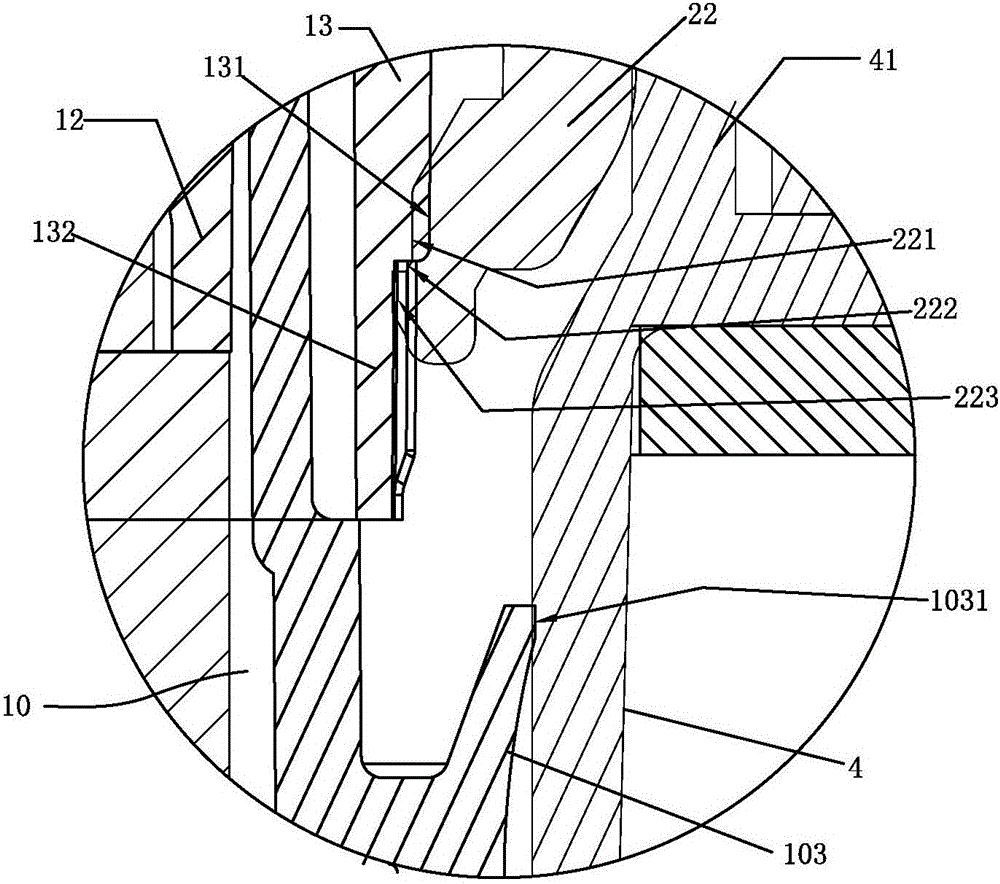

[0020] Such as figure 1 , figure 2 , image 3 As shown, a lotion pump that prevents opening and leakage during transportation includes a press head, a lock cover 2, a thread 3, a body 4, a main column 5, an auxiliary column 6, a piston 7, a glass ball 8, a spring 9 and a waterproof ring 10 , the press head 1 includes a liquid outlet channel 11, a catheter 12 and a locking sleeve 13 with external threads; the locking cover 2 includes an inner locking sleeve 21 located in the top cover and a central locking sleeve 22 with internal threads; the body 4 The upper end is provided with a threaded head 41 and a flange 42, and the body of the lower part of the flange 42 has an air supply hole; the upper end of the main column 5 has a connecting head 51, the lower end has a baffle plate 52, and the lower part of the baffle plate has a lower connecting head 53; the piston 7 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com