Right-angle overturning mechanism of ceramic tile corner wrapping machine and ceramic tile corner wrapping machine

A technology of turning mechanism and wrapping angle, which is applied in the directions of packaging, conveyor objects, transportation and packaging, etc., can solve the problems of inaccurate positioning, dislocation of flipping, and incomplete flipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

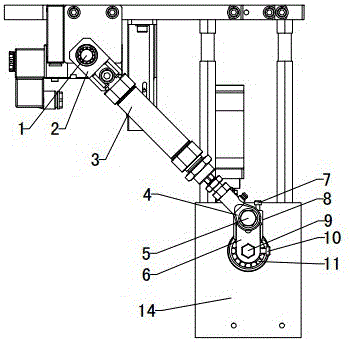

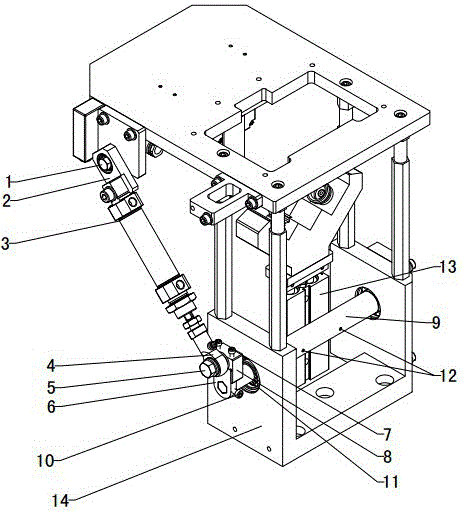

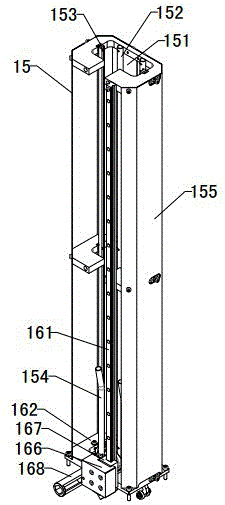

[0027] Figure 1~7 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~7 The present invention will be further described.

[0028] Refer to attached Figure 1~2 : A right-angle turning mechanism of a tile angle wrapping machine, comprising a turning body 13 and a turning bracket 14, the turning body 13 is rotatably installed inside the turning bracket 14 through the turning shaft 9, preferably, the middle and lower part of the turning body 13 passes through the turning shaft 9 is rotatably installed in the lower part of the turning bracket 14, wherein one side of the turning body 13 is fixedly connected to the turning shaft 9, the two ends of the turning shaft 9 pass through the two sides of the turning bracket 14, and the two ends of the turning shaft 9 pass through at least One end is provided with a linear push mechanism that can push the turning shaft 9 to rotate 90 degrees, and the linear pusher is arranged on the outside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com