Rotating blanking device for numerical control cutting machine

A cutting machine and punching technology, which is applied in the field of numerical control cutting machines, can solve problems such as low punching height control accuracy, inconvenient punching adjustment, and incomplete punching, so as to achieve good punching effect, convenient replacement, and punching. The effect of high cutting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the structure of the invention is described in detail with reference to the drawings.

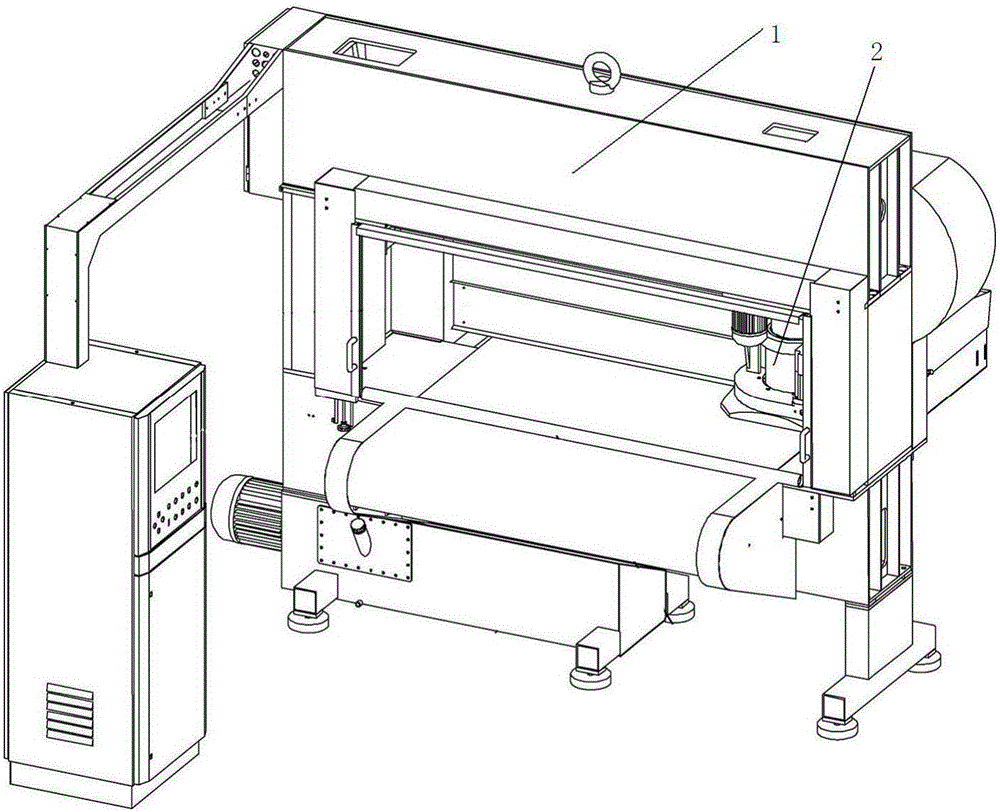

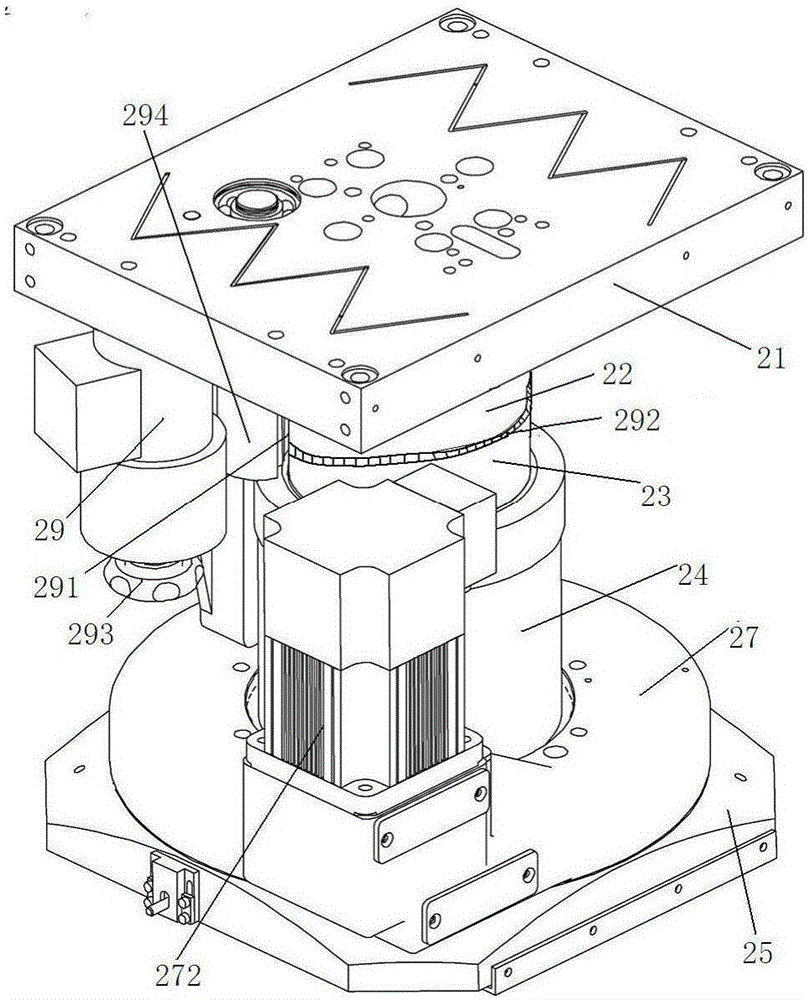

[0028] As shown in the figure, a rotary punching device for a CNC cutting machine includes a gantry body 1 and a controller of the CNC cutting machine. The body 1 is provided with a rotary punching device 2, which includes:

[0029] Horizontal mobile platform 21, which can move horizontally is located on the body 1;

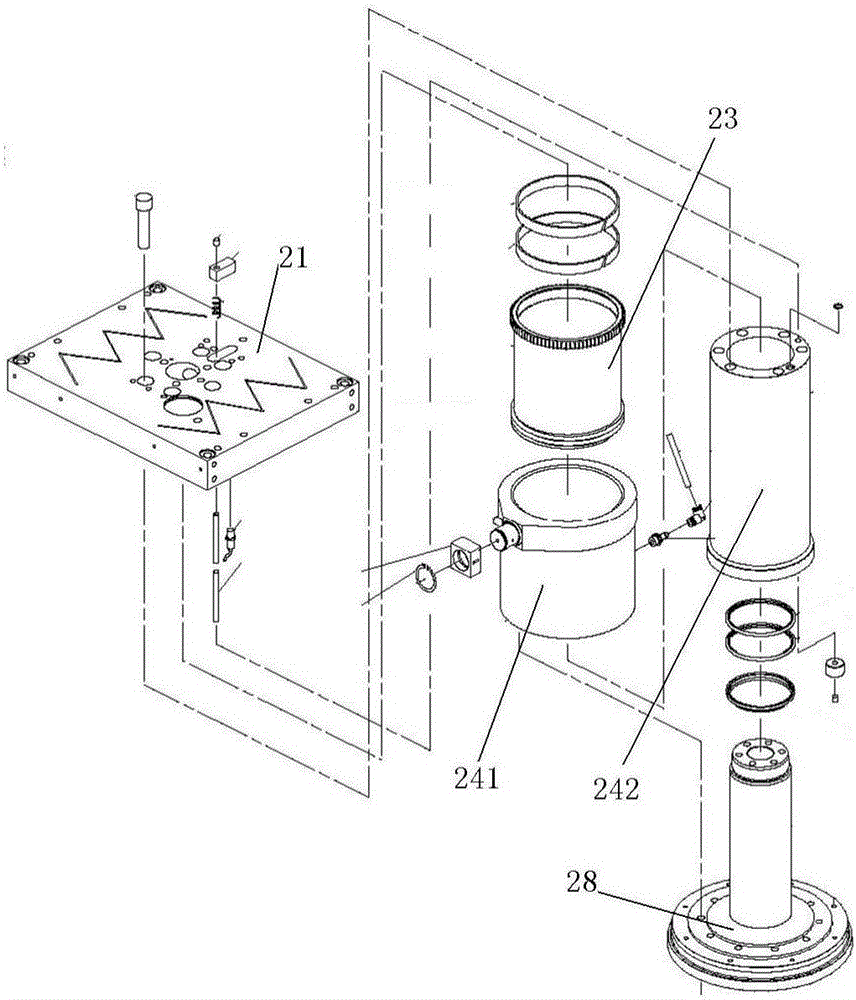

[0030] The punching mechanism includes a cylinder 22 arranged on a horizontal moving table 21. The lower end of the cylinder 22 can be raised and lowered with a rotating cylinder liner 23. The outer wall of the lower end of the rotating cylinder liner 23 is connected to the inner wall of the oil cylinder 24 through threads and drives the oil cylinder 24. , the cylinder 22, the rotating cylinder liner 23, and the oil cylinder 24 are provided with a piston assembly;

[0031] The rotating mechanism comprises a suspension plate 25 provided with a cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com