Pipeline inner wall spraying robot

A spraying robot and pipeline technology, applied in the field of robots, can solve the problems of lack of 4-axis linkage and restrictions on spraying methods, and achieve the effects of compact structure, long output stroke, and prevention of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

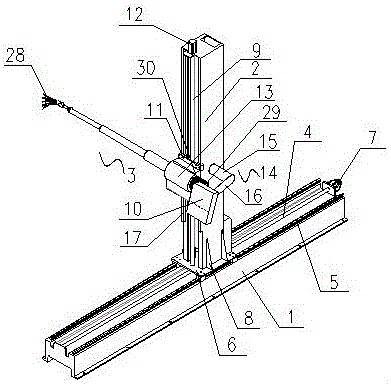

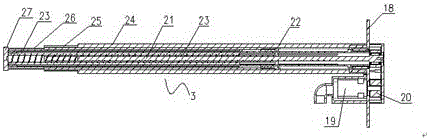

[0024] Such as figure 1 As shown, a pipeline inner wall spraying robot includes a base 1 , a column 2 vertically arranged above the base 1 , and a multi-section servo electric cylinder 3 vertically arranged on one side of the column 2 .

[0025] The top surface of the base 1 is provided with a groove along the middle of its length direction and retains its two ends. A ball screw 4 is connected between the two ends. A linear guide rail A5 is installed on the top, and a freely slidable slider A6 is installed on the linear guide rail A5. One end of the ball screw 4 is connected to a main motor 7 that drives the ball screw 4, and the main motor 7 is fixedly installed. on the end face of base 1.

[0026] The column 2 is vertically fixedly connected to the slide block A6 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com