Automatic loading and unloading laser processing machine tools for round tube workpieces

A technology of automatic loading and unloading and laser processing, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc. The effect of labor costs and a wide range of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

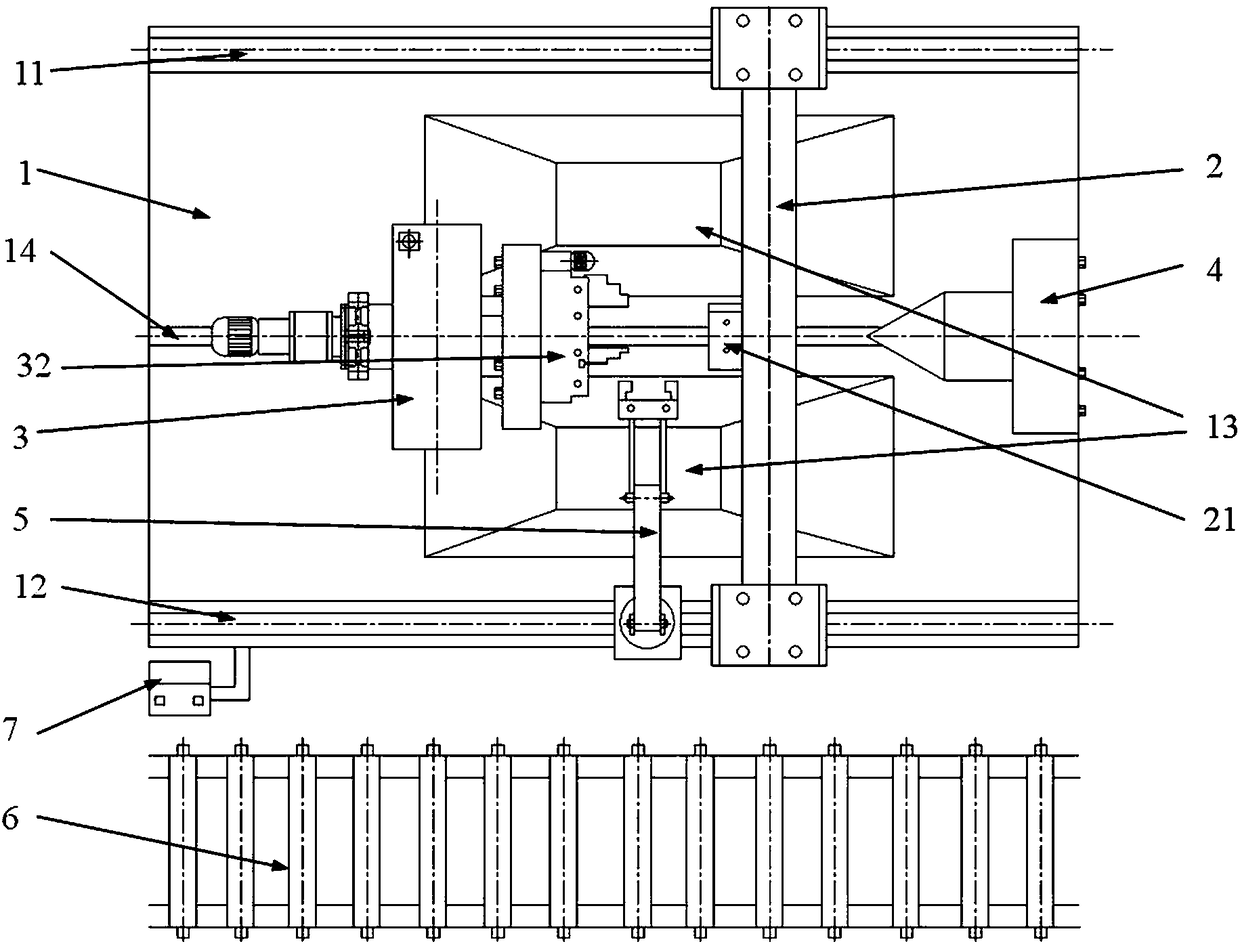

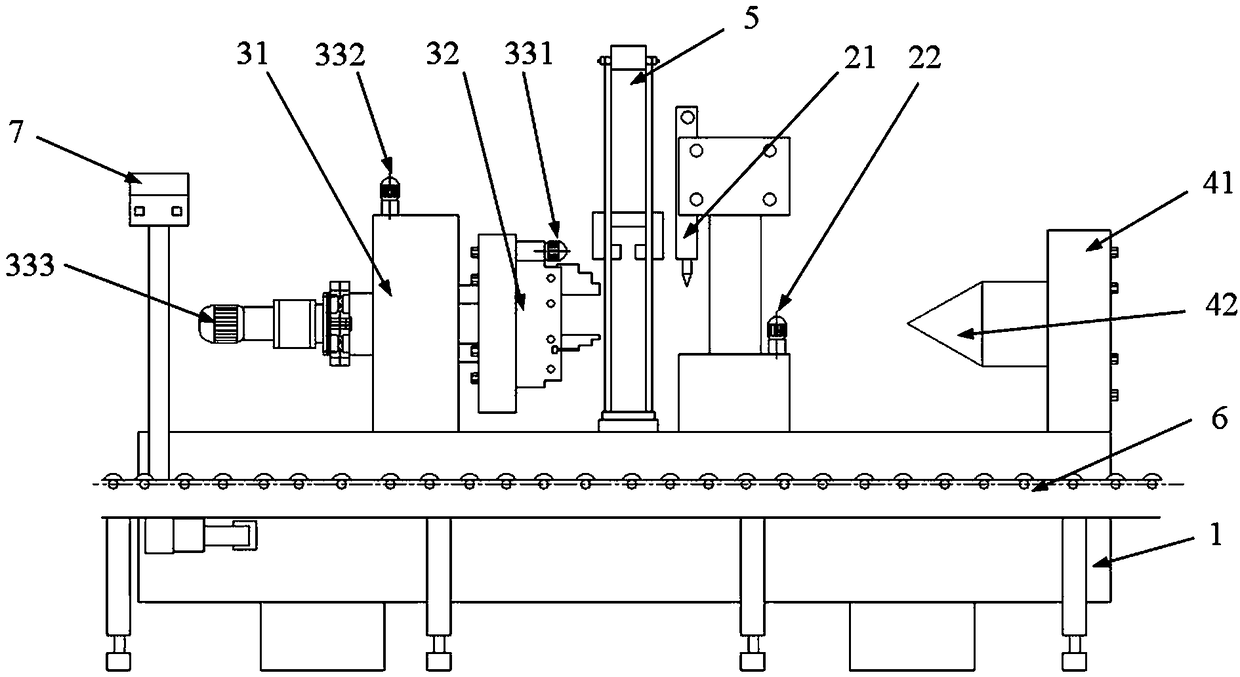

[0042] Generally speaking, for the bed 1 of the machine tool, the end with the headstock box is the front end, and the opposite end is the tail end, as shown in the figure, the end with the tailstock 4 is the tail end, and the clamp assembly One end of 3 is the head end. Although the clamp assembly 3 shown in the figure is a movable part, it does not affect the understanding of the head and tail of the bed 1.

[0043] In addition, generally relative to the head and tail, for example, on a common lathe, the side where the operator is located is the front side, and the side opposite to the front side is the rear side. In the figure, the side where the feeding roller table 6 is located is the front side, and the side where the linear guide rail 11 is located is the rear side.

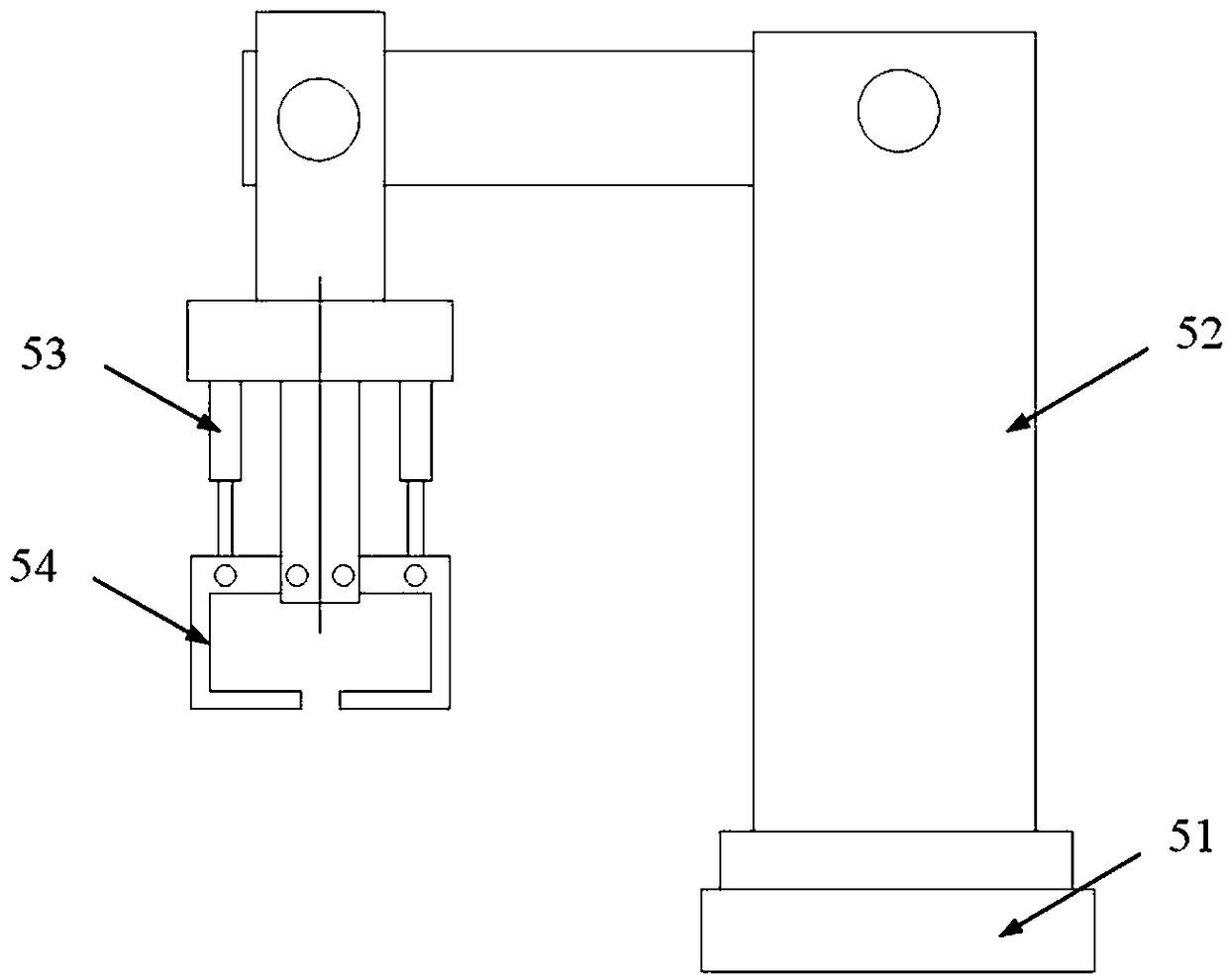

[0044] see figure 1 and 2 A laser processing machine tool for automatic loading and unloading of round tube workpieces shown in , its basic structure includes three guide rails, of which the linear guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com