Auto Flip Structure

A technology that automatically flips and rotates blocks, which can be used in metal processing equipment, feeding devices, manufacturing tools, etc., and can solve problems such as inability to flip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

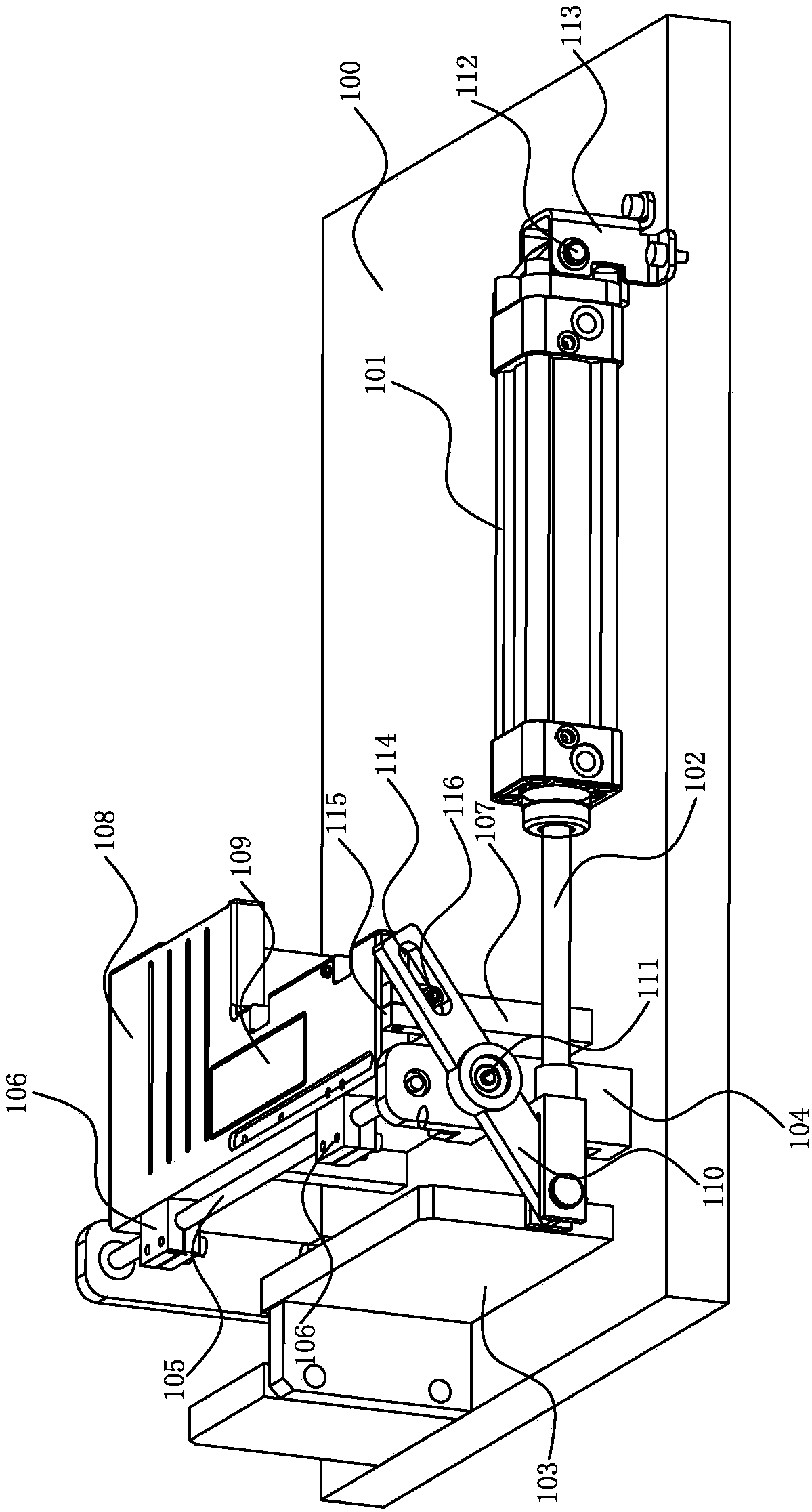

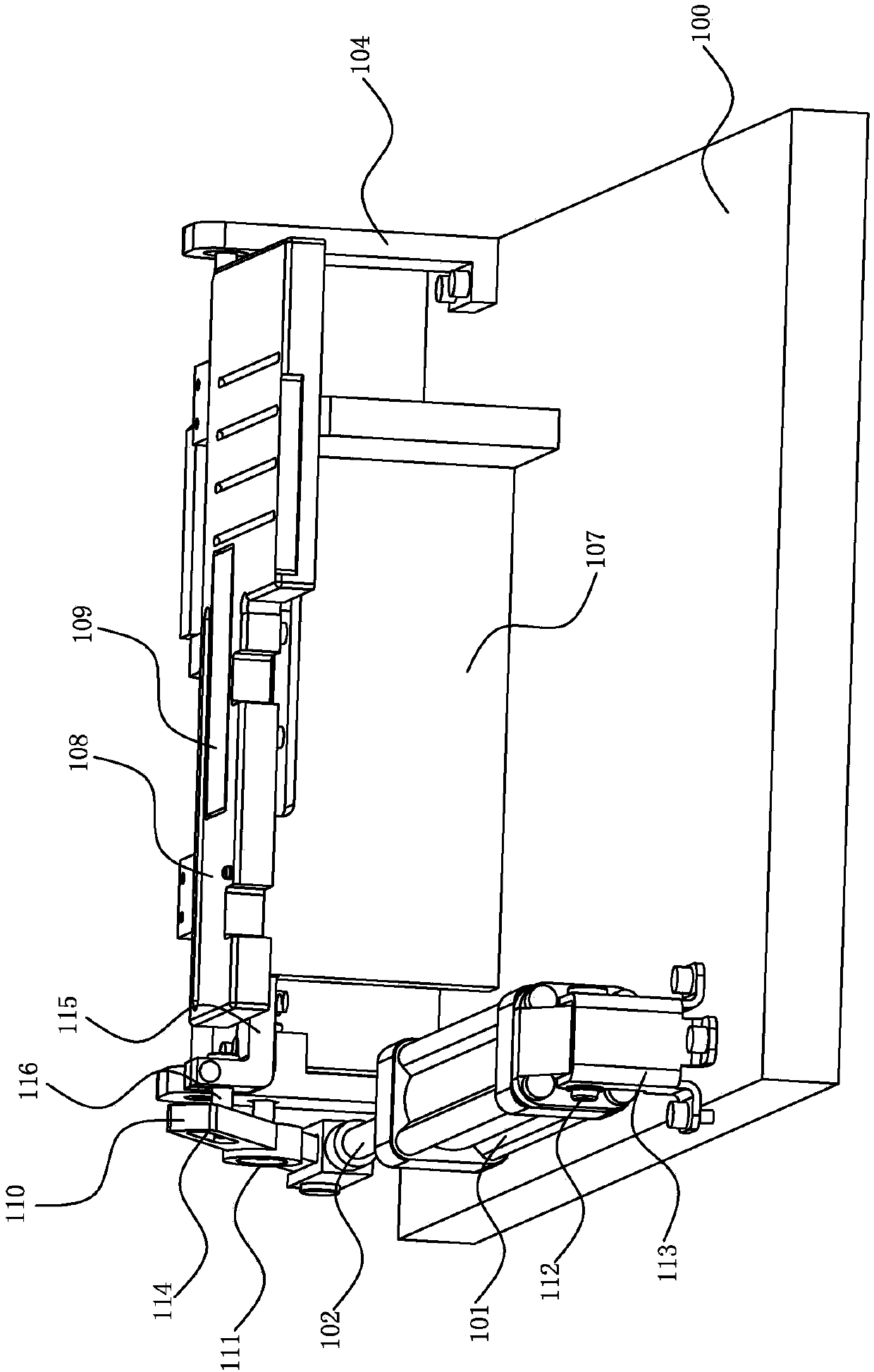

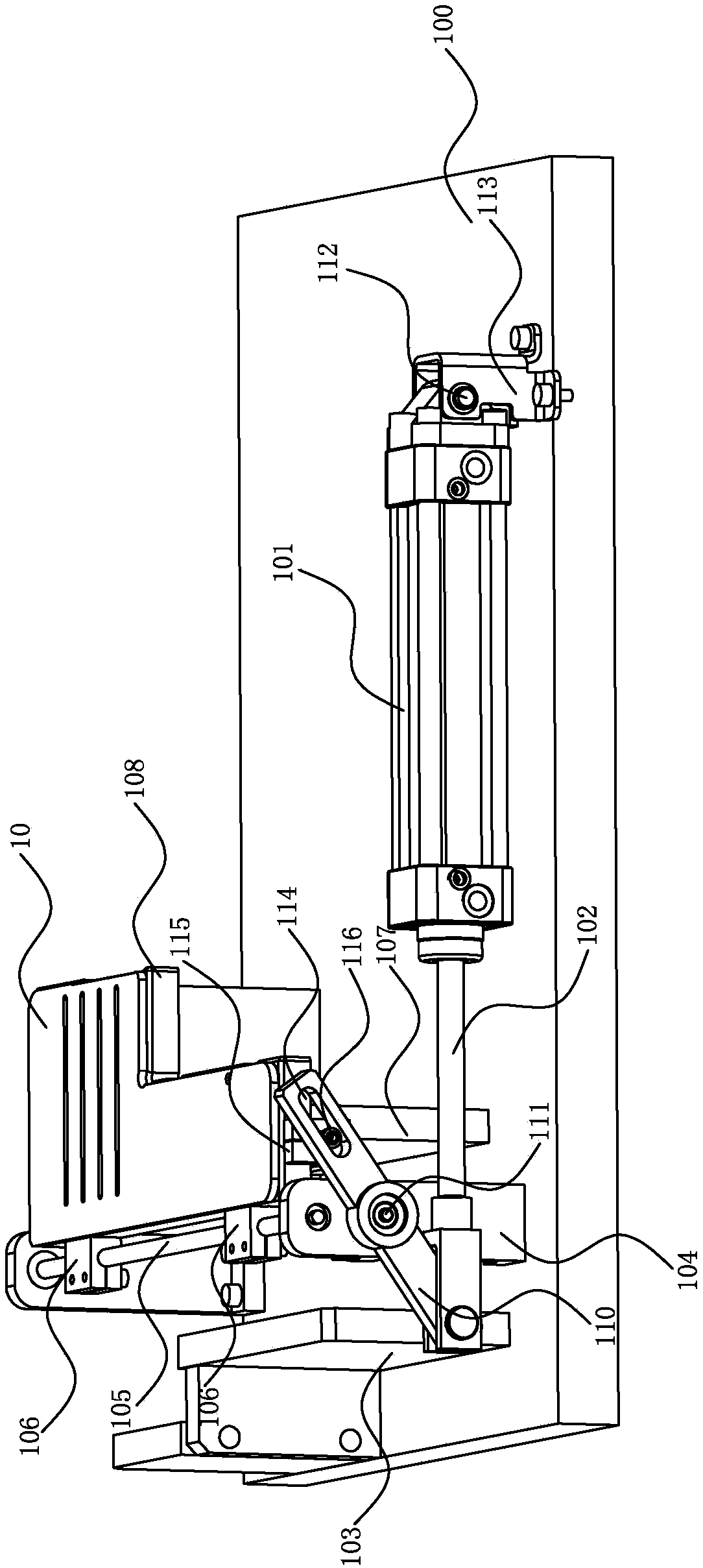

[0024] see figure 1 , figure 2 and image 3 shown, where figure 1 A schematic diagram showing an angle of the automatic flipping structure of the present invention in the first state, figure 2 A schematic diagram showing another angle of the automatic flipping structure of the present invention in the first state, image 3 A schematic diagram of the automatic reversing structure of the present invention in the second state is shown. Wherein, the first state is a state where the stamping product 10 to be processed is not placed, and the second state is a state where the stamping product 10 to be processed is placed.

[0025] In a preferred embodiment, the automatic overturning structure of the present invention is used to overturn the stamping product 10 covered with holes or grooves. The automatic overturning structure includes:

[0026] Bottom plate 100;

[0027] A cylinder 101, which is movable up and down on the base plate 100, the cylinder 101 has a horizontally te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com