a regulator

An adjuster and adjustment hole technology, applied in the field of adjusters, can solve the problems that parallel lines and transcondylar lines cannot be parallel, no adjustment tools, etc., and achieve the effect of improving calibration accuracy and easy to grasp.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

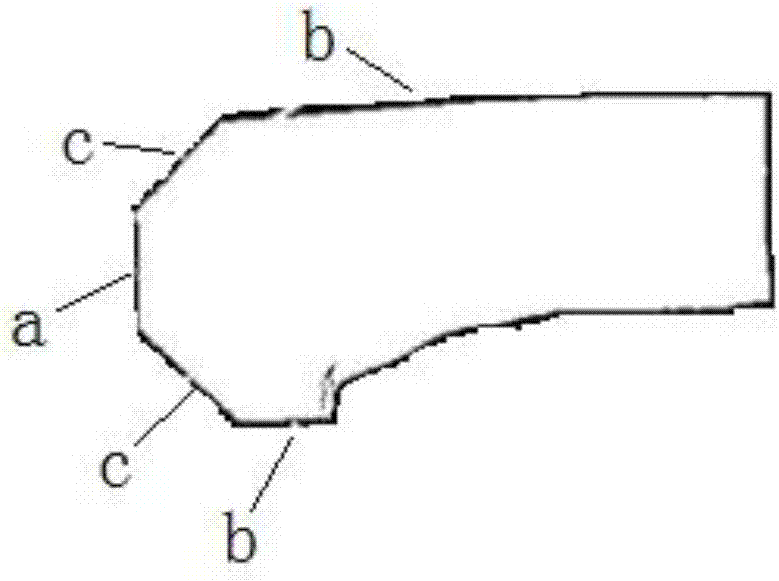

[0043] This embodiment provides an adjuster, such as Figure 4 As shown, including a body 10, a pair of reference holes 1 and several pairs of adjustment holes 2, 3, 4, 5, 6, 7 are provided on the body 10, and the distance between the pairs of reference holes 1 is set so that it It is suitable for being fitted and set on the fixed nail to be adjusted at the same time; a pair of adjustment holes 2, 3, 4, 5, 6 with the smallest angle difference between the line between the center of the circle and the line between the centers of the paired reference holes 1 , 7, the angle difference between the connecting line of the center of the circle and the connecting line of the center of the paired reference holes 1 is at most 2°; any two pairs of the adjustment holes 2, 3, 4, 5 with the closest inclination degree, The angle difference between the lines connecting the centers of 6 and 7 is at most 2°.

[0044] For the adjuster of this embodiment, when using a calibration tool to nail two...

Embodiment 2

[0053] This embodiment provides a method of using the regulator, refer to Figure 4 shown, including the following steps:

[0054] S1. Fit the pair of reference holes 1 on the body 10 to the pair of fixing nails to be adjusted;

[0055] S2. Find a pair of adjustment holes 2, 3, 4, 5, 6, 7 where the connecting line between the center of the circle and the condylar line is parallel or the closest parallel;

[0056] S3. Reset new fixing nails at the found positions of the pair of adjustment holes 2, 3, 4, 5, 6, and 7.

[0057] The use method of the adjuster in this embodiment can adjust the setting position of the fixing nail when the connection line of the two fixing nails is not parallel to the through-condyle line, so that the adjusted connection line of the fixation nail and the through-condyle line can reach a higher level. Good parallel.

[0058] When the positions of the pair of adjustment holes 2, 3, 4, 5, 6, and 7 found are not suitable for setting new fixing nails, t...

Embodiment 3

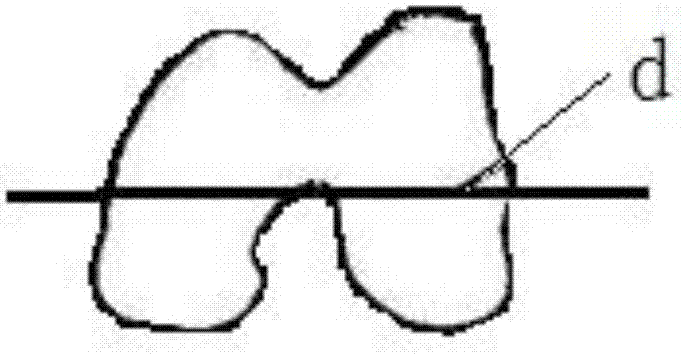

[0063] This embodiment provides an adjuster, which is a deformation on the basis of Embodiment 1, such as Figure 5 As shown, the difference is: it also includes an inclination angle structure, (this inclination angle structure no longer takes the intersection of a pair of reference holes 1 on the body 10 and the edge of the body 10 as the center of the circle to set the angle mark, but resets the inclination angle structure), so The inclination angle measuring structure is installed on the body 10 for measuring the angle difference between the condylar line and the line connecting the centers of the paired reference holes 1 .

[0064] The tilt measuring structure includes: a first measuring rod 21, one end of which is rotatably mounted on the body 10, and the other end is a pointer. The number of angles is 11; the second measuring rod 22 is arranged parallel to the first measuring rod 21, and the distance between the first measuring rod 21 and the first measuring rod 21 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com