Method for producing high-fineness silkworm cocoon silk through silkworm artificial feed

A technology of artificial feed and fine denier is applied in the fields of sericulture and textile fiber production, which can solve the problems of shortening the larval stage of the three-sleeping silkworm, the yield of silkworm cocoons, and the reduction of production safety, so as to solve the problem of significantly shortening the larval stage and saving money. Breeding time and cost, the effect of reducing feed cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

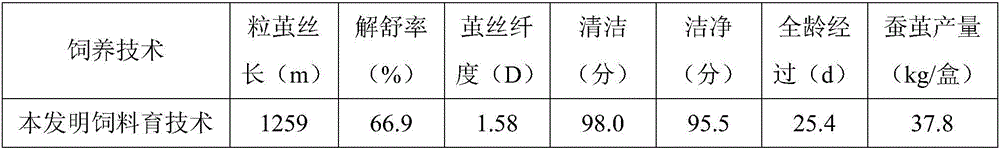

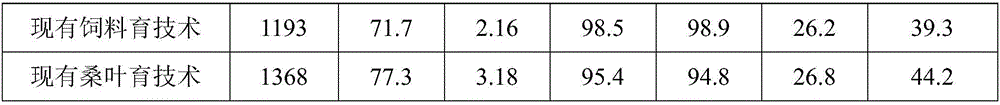

Embodiment 1

[0048] The four-sleep silkworm variety Jingsong×Haoyue was selected, which is a combination of high-yield and high-quality first-generation hybrid silkworm varieties commonly raised on mulberry leaves in Jiangsu, Shandong, Zhejiang, Anhui, Sichuan and other provinces.

[0049] (1) The existing mulberry leaf breeding technology raises Jingsong × Haoyue varieties

[0050] Fresh mulberry leaves are used to raise the variety Jingsong×Haoyue. The temperature of the breeding environment is 27.0°C to 28.0°C for the 1st to 2nd age, 23.0°C to 25.0°C for the 3rd to 4th age, and 22.0°C to 25.0°C for the 5th age; the relative humidity of the breeding environment is 85% for the first age. ~95%, 80%~90% in the 2nd age, 65%~85% in the 3rd~5 age. When 1% to 3% mature larvae are seen in the late stage of the 5th instar larvae, use 50 ml of boarding agent for each larvae (20,000 to 25,000) of silkworm eggs, add water to 2 liters, mix well, spray on the body, and let them mature after 10 to 14 h...

Embodiment 2

[0067] The four-sleep silkworm variety Haoyue×Jingsong was selected. This variety is a high-yield and high-quality first-generation hybrid silkworm variety combination commonly raised on mulberry leaves in Jiangsu, Shandong, Zhejiang, Anhui, Sichuan and other provinces.

[0068] (1) Breeding Haoyue×Jingsong varieties with existing mulberry leaf breeding technology

[0069] Fresh mulberry leaves are used to raise Haoyue×Jingsong variety, the breeding environment temperature is 27.0℃~28.0℃ for the 1st to 2nd age, 23.0℃~25.0℃ for the 3rd to 4th age, 22.0℃~25.0℃ for the 5th age; the relative humidity of the breeding environment is 85% for the 1st age ~95%, 80%~90% in the 2nd age, 65%~85% in the 3rd~5 age. When 1% to 3% mature larvae are seen in the late stage of the 5th instar larvae, use 50 ml of boarding agent for each larvae of silkworm eggs, add water to 2 liters, mix well and spray on the body, and let the mature larvae climb up the grid by themselves after 10 to 14 hours Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com