Corrosion protective layer system, corrosion protective bearing component and method for protecting a bearing component from corrosion

A technology of bearing components and layer systems, applied in the direction of bearing components, bearings, anti-corrosion coatings, etc., can solve the problems of re-pollution, high cost, damaged bearings, etc., and achieve the effect of long-term reliable anti-corrosion and reasonable cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

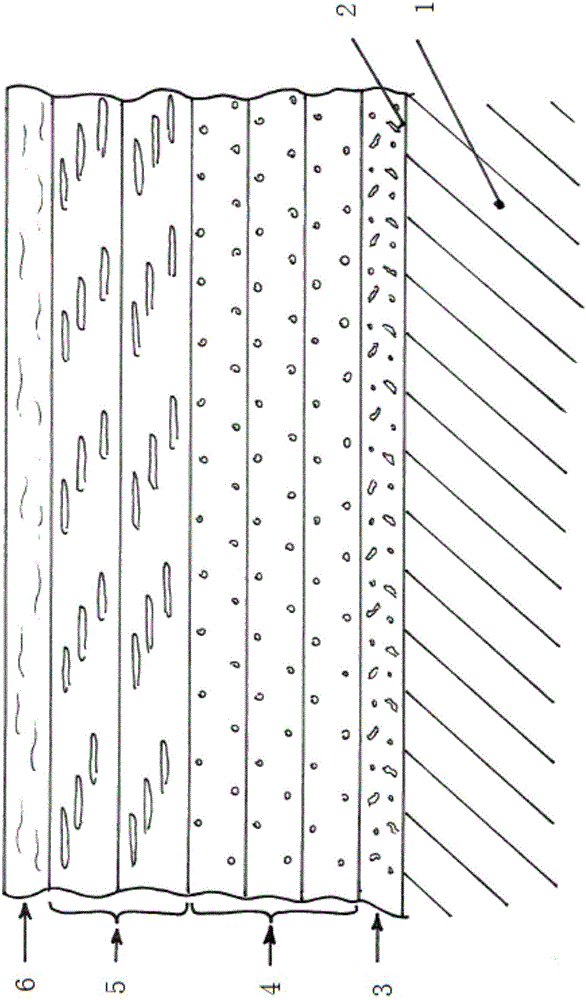

[0037] figure 1 A schematic view of an exemplary embodiment of a coated bearing assembly 1 is shown. The figure is greatly simplified and not to scale, and only shows a section of the bearing assembly 1 . The bearing component 1 can be, for example, a bearing ring of a rolling element bearing or a plain bearing or the like. In particular, the bearing assembly 1 is formed as an assembly of a large bearing of a wind turbine or other large machine. The bearing assembly 1 can be made of steel, in particular rolling element bearing steel.

[0038] The base layer 3 is applied to the surface area 2 of the bearing component 1 . The surface region 2 can extend over the entire surface of the bearing component 1 with the exception of raceways and runners, which are not shown in the figures, or only over a partial region of the bearing component 1 . Base layer 3 comprises polyurethane, zinc and vinylphosphonic acid.

[0039] As an alternative to vinylphosphonic acid, the base layer 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com