An automatic candy vending machine

A vending machine and candy technology, applied to instruments, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., can solve problems such as no occurrence, achieve broad application prospects, and improve work efficiency , Reduce the effect of manual labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

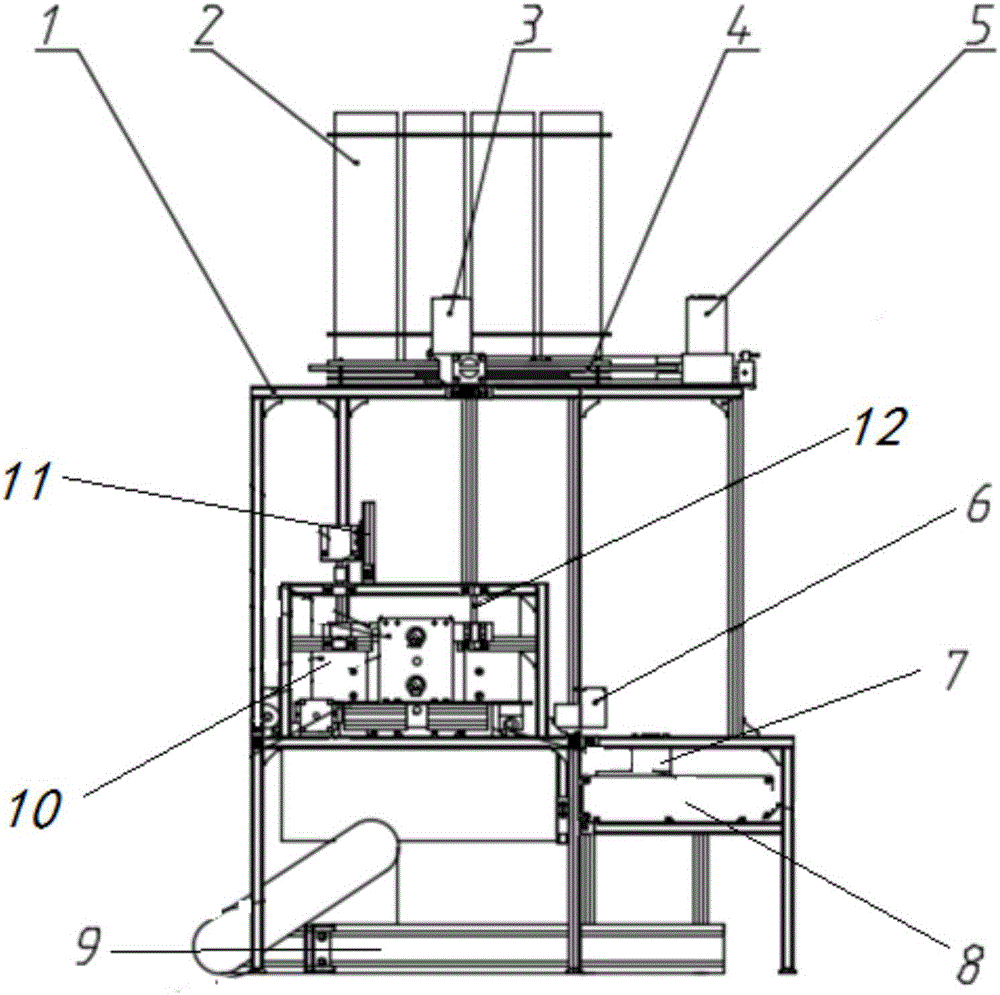

[0032] An automatic candy vending machine, its structure is as in question 1 and figure 2 As shown, the vending machine includes:

[0033] Rack 1;

[0034] Candy storage and selection unit: including 4 candy storage buckets 2, a partition subunit 4 arranged under the candy storage bucket 2, a push rod subunit connected to the partition subunit 4, and a control unit for controlling the movement of the push rod And the sensor arranged under the candy storage barrel 2 for detecting the weight loss of candies; wherein, the partition subunit 4 includes five partitions, which are No. 1 partition, No. 2 partition, and No. 3 partition from top to bottom. plate, No. 4 partition and No. 5 partition, and the push rod subunit includes No. 1 push rod 5 connected with No. 2 partition and No. 2 push rod 3 connected with No. 4 partition, and No. 1 push rod 5 and The No. 2 push rod 3 is connected with the control unit to control the movement of the No. 2 partition and the No. 4 partition re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com