Automatic sampling barrel for pile bottom slurry

An automatic sampling and mud technology, applied in sampling, sampling device, measuring device and other directions, can solve the problem of not fully representing the mud at the bottom of the hole, and achieve the effect of simple structure, convenient use and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

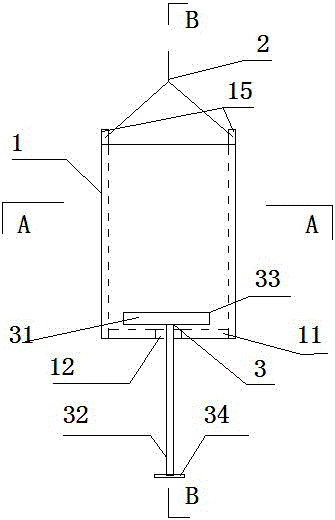

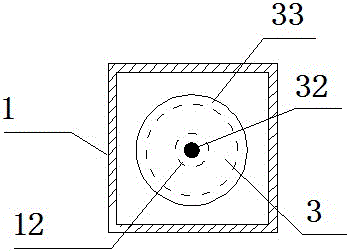

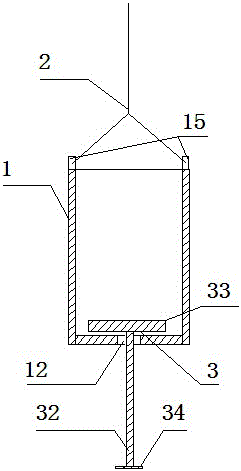

[0016] Such as Figure 1 to Figure 4 As shown, the present invention includes a barrel body 1, a lead wire 2 and a back sealer 3, the lead wire 2 is arranged above the barrel body 1, a bottom plate 11 of the barrel body 1 is provided with a barrel bottom hole 12, and the back sealer 3 includes The bottom cover plate 31 and the stop bar 32 arranged at the bottom of the back cover plate 31 , the back cover plate 31 is arranged in the bucket body 1 , and the stop bar 32 is movably connected with the bottom plate 11 through the bucket bottom hole 12 .

[0017] A sealing ring 33 is sheathed on the bottom cover plate 31 , and a limiting piece 34 is provided at the lower end of the limiting rod 32 . The sealing ring 33 is a rubber ring, which is sleeved on the outer periphery of the bottom cover 31 or arranged below the bottom cover 31 to play a sealing role and prevent the mud from leaking when the barrel is pulled upwards. When sampling the sampling bucket is put down to the botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com