High-temperature electric furnace provided with optical measurement channel

An optical measurement and electric furnace technology, applied in the field of measurement, can solve the problems of troublesome loading and unloading, difficult to solve the material of the extension rod, and difficult to design and manufacture the end knife edge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

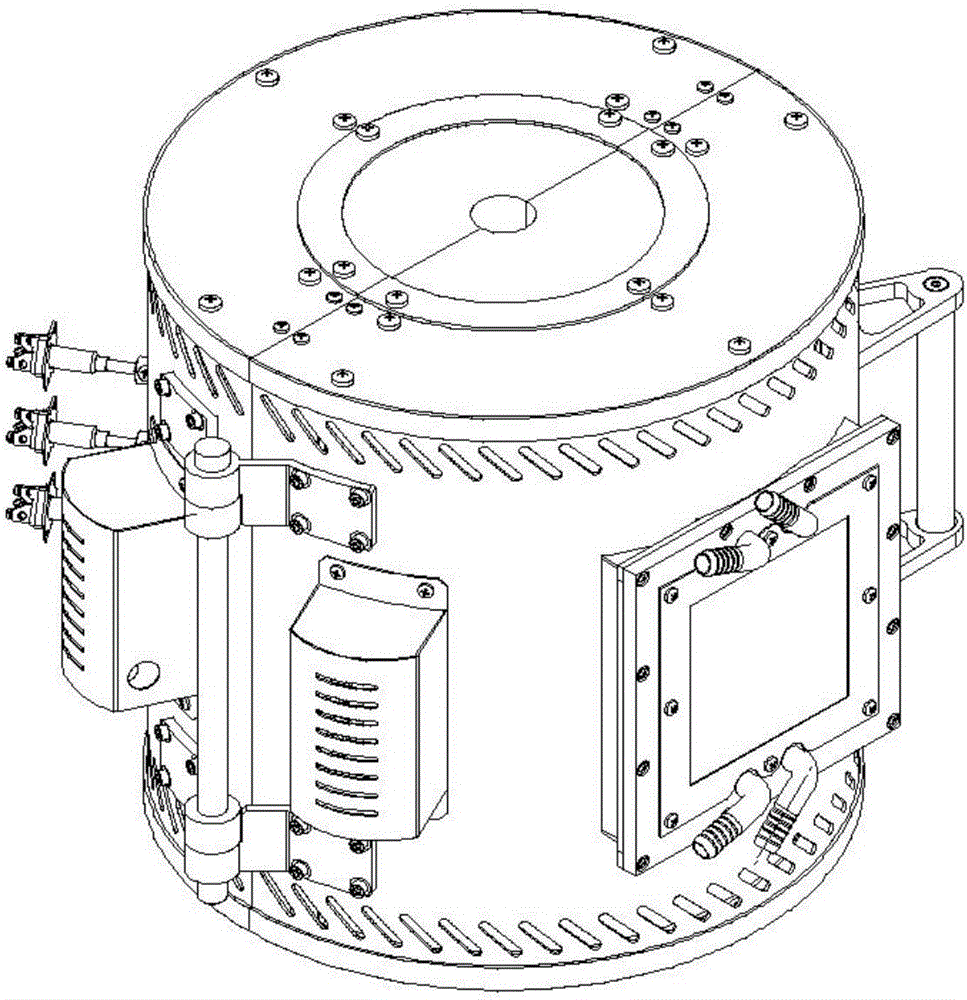

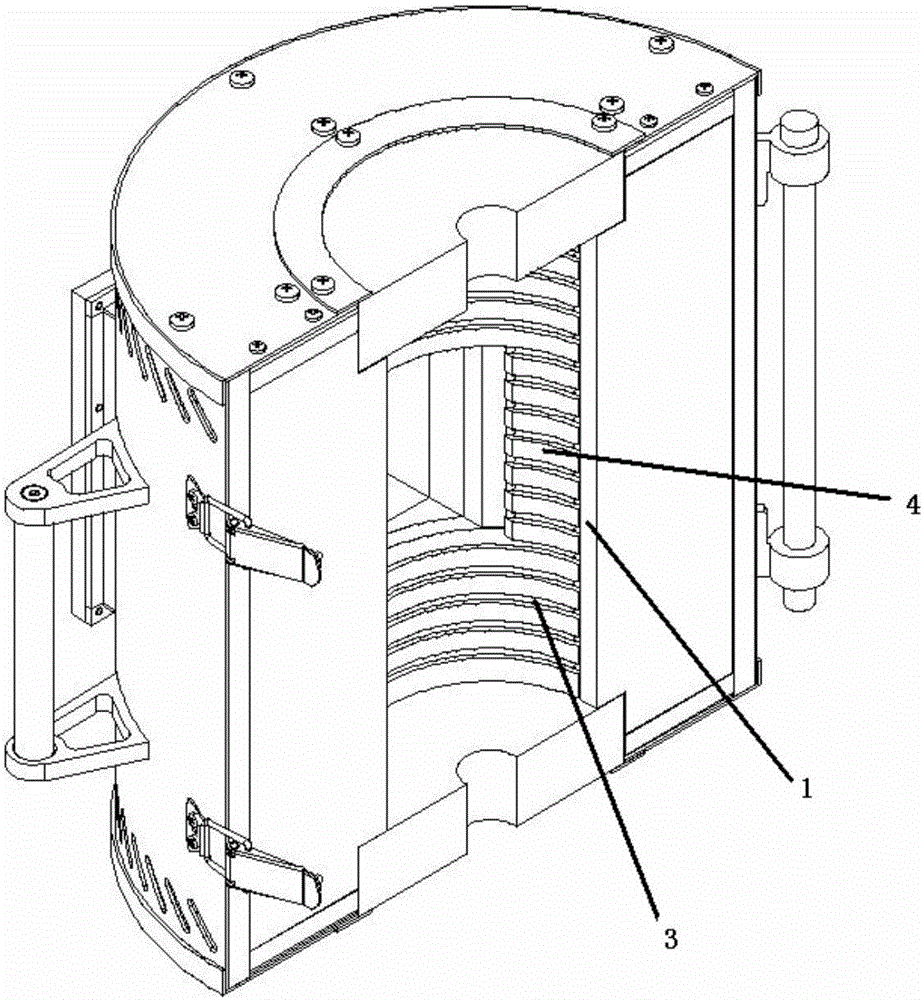

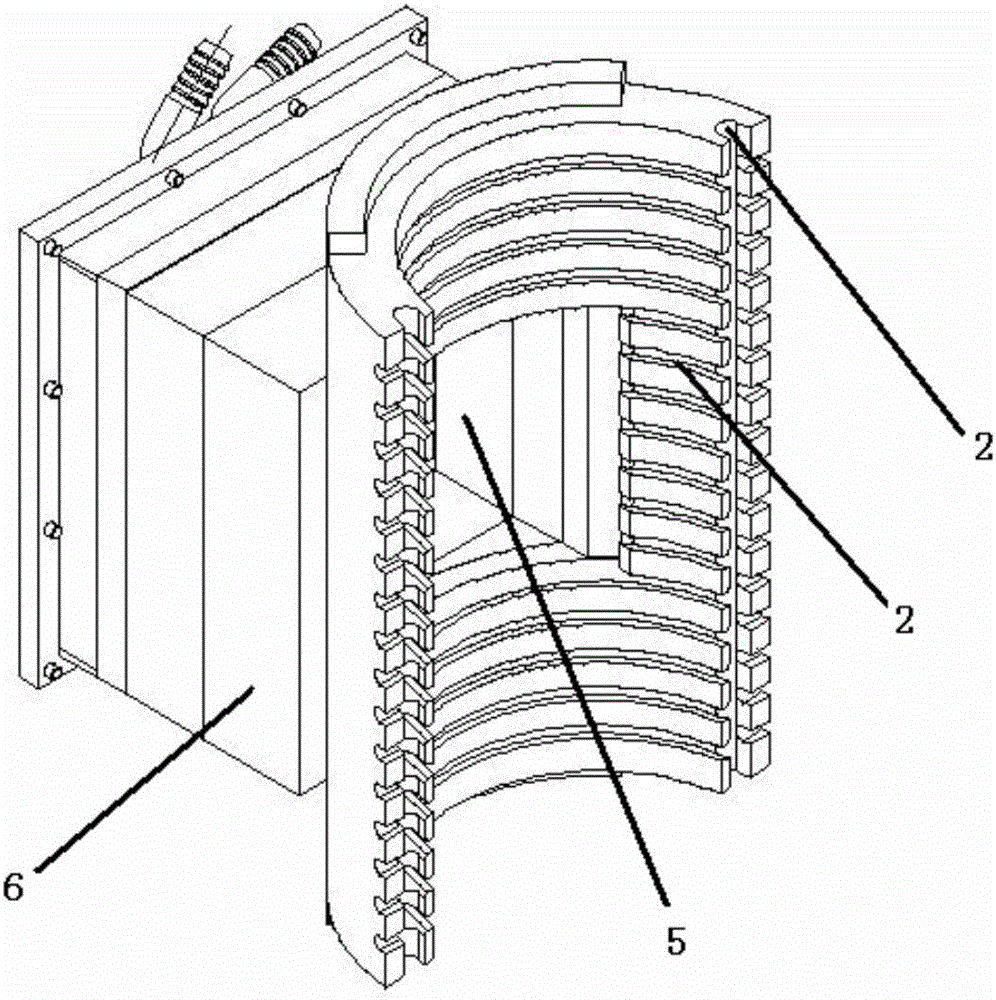

[0017] See attached Figure 1~4 As shown, this kind of high-temperature electric furnace with optical measurement channel has a power of .5kW, 1.2kW during heat preservation, and the temperature fluctuation in the furnace after heat preservation is within ±2°C. When measuring, the electric furnace is hung on the material testing machine , the electric furnace is a double semi-cylindrical split structure. The outer dimensions of the furnace shell of the electric furnace are φ380×380mm high. The size of the furnace tube 1 of the electric furnace is 150mm inside diameter×300mm high. Aluminum oxide ceramics, the purity of aluminum oxide is more than 90%. High-purity aluminum oxide is very effective for the electrical insulation and chemical stability of the electric cathode wire in the furnace, which can ensure the long-term stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com