A Falling Film Evaporator with Gravity Separation

An evaporating device, falling film technology, applied in the field of falling film evaporating device, can solve problems such as wet steam easily entering the return air pipe, poor evaporation effect, and affecting the life of the compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

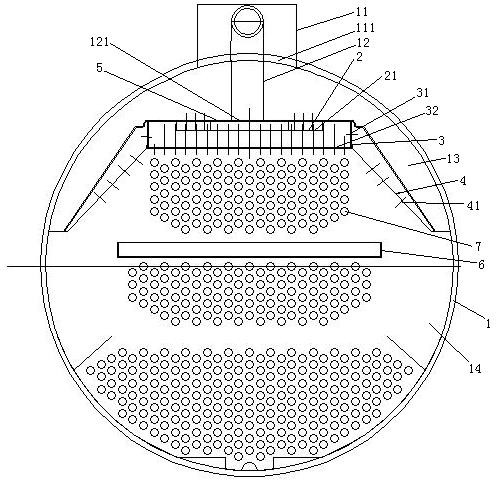

[0030] Embodiment one, see figure 1 , a falling film evaporation device with gravity liquid separation, including an evaporator cylinder 1 and a heat exchange tube 7.

[0031] An air return pipe 11 and a liquid inlet pipe 12 are arranged above the evaporator cylinder 1 . The evaporator cylinder 1 is provided with a static pressure equalizing pan 2 , a gravity distribution pan 3 and a gas baffle 4 . The air baffle plate 4 and the gravity distribution plate 3 are connected together to divide the evaporator cylinder 1 into an upper space 13 and a lower space 14 .

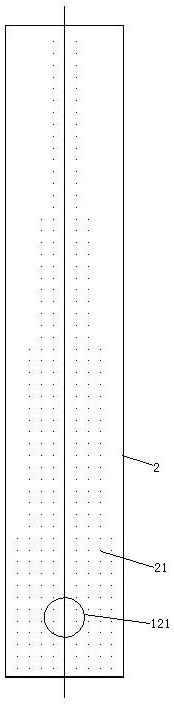

[0032] The static pressure equalizing pan 2 is located above the gravity distribution pan 3 . The bottom of the static pressure equalizing pan 2 is provided with a communication hole 21 communicating with the gravity distribution pan. The top of the static pressure equalizing pan 2 is covered with a top plate 5 . The outlet 121 of the liquid inlet pipe is arranged on the top plate 5 and communicates with the static...

Embodiment 2

[0038] Embodiment two, the difference with embodiment one is:

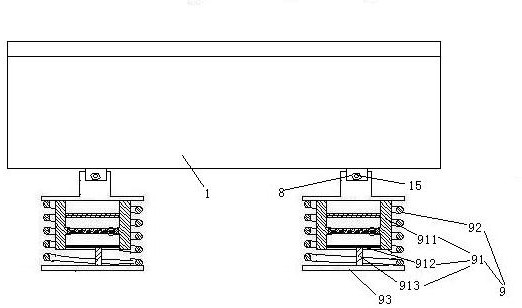

[0039] see image 3 , The evaporator cylinder 1 is provided with at least two supporting feet 9 . The supporting foot 9 includes a vertical damping cylinder 91 and a damping spring 92 sleeved on the damping cylinder. The damping oil cylinder 91 includes a damping oil cylinder body 911 . The damping oil cylinder body 911 is connected with the evaporator cylinder body 1 through bolts 15 and nuts 8 . A first piston 912 is disposed inside the damping oil cylinder body 911 . The first piston 912 is connected to the supporting seat 93 through the piston rod 913 . One end of the damping spring 92 is affixed together with the piston rod 913, and the other end is affixed together with the cylinder body 911 of the damping oil cylinder.

[0040] see Figure 4 , the nut 8 includes a main body section 811 , an anti-swing section 812 and a thread alignment maintaining mechanism 82 . The outer end of the main body section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com