Rotary compressor

A rotary compressor and an integrated technology, applied in the field of compressors, can solve the problems of limited maximum displacement and achieve the effects of reducing area, reducing thickness and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

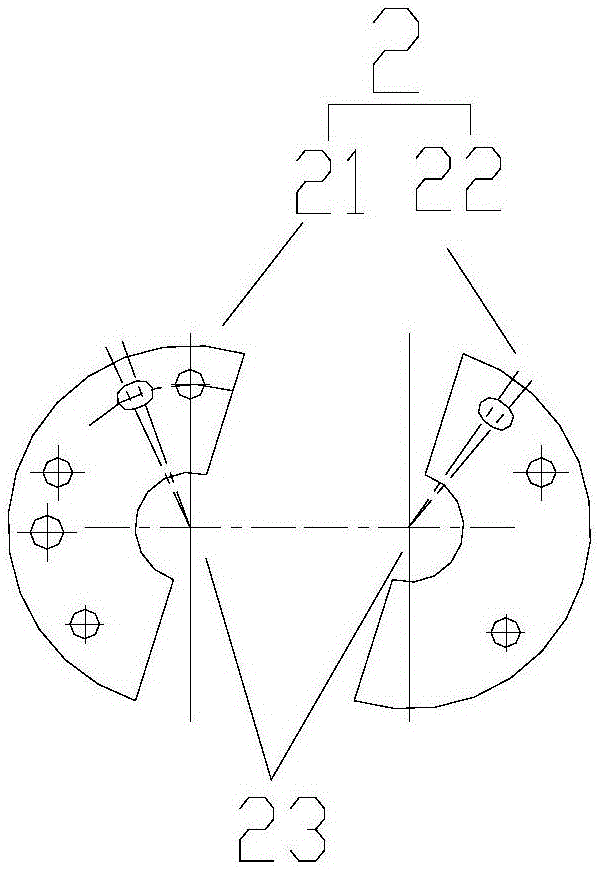

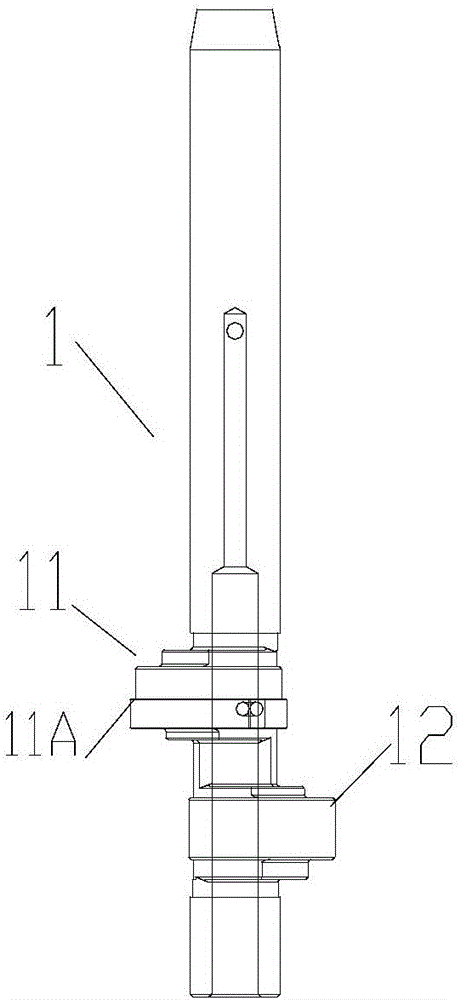

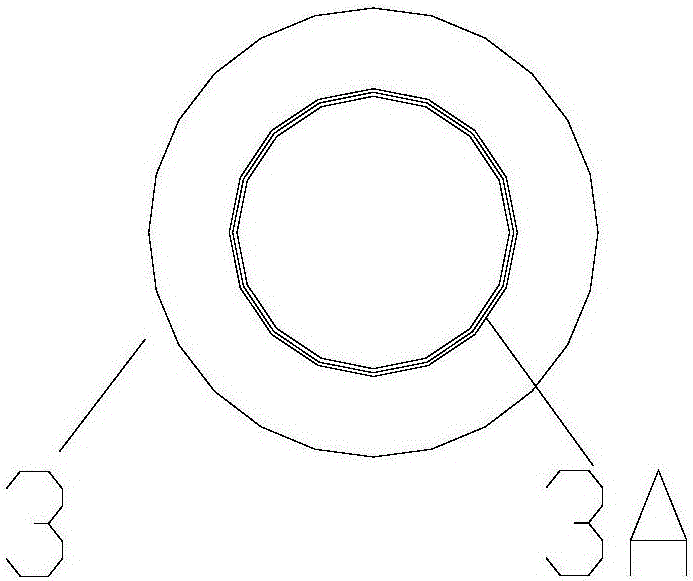

[0029] Such as Figure 1-3 As shown, the present invention provides a rotary compressor, which includes a crankshaft 1, a first cylinder assembly and a second cylinder assembly, and a partition 2 is also arranged between the first cylinder assembly and the second cylinder assembly , wherein, the partition 2 is a detachable structure in which two or more partition units are assembled and detachable.

[0030] 1. In the rotary compressor of the present invention, by setting the partition between the first cylinder assembly and the second cylinder assembly as a detachable structure in which two or more partition units are assembled and detachable, it can In the process of assembling with the crankshaft, the detachable partition is moved to the corresponding position on the crankshaft to be assembled and then assembled, without the need to assemble the two by passing the crankshaft through the center hole of the partition, As a result, the eccentric diameter of the crankshaft no l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com