Walking support for mine excavation face, walking method and roadheader

A tunneling face, walking technology, used in mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems affecting the quality of the roadway, the broken roadway roof, etc., to ensure the quality of the roadway, improve the construction efficiency, labor Intensity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

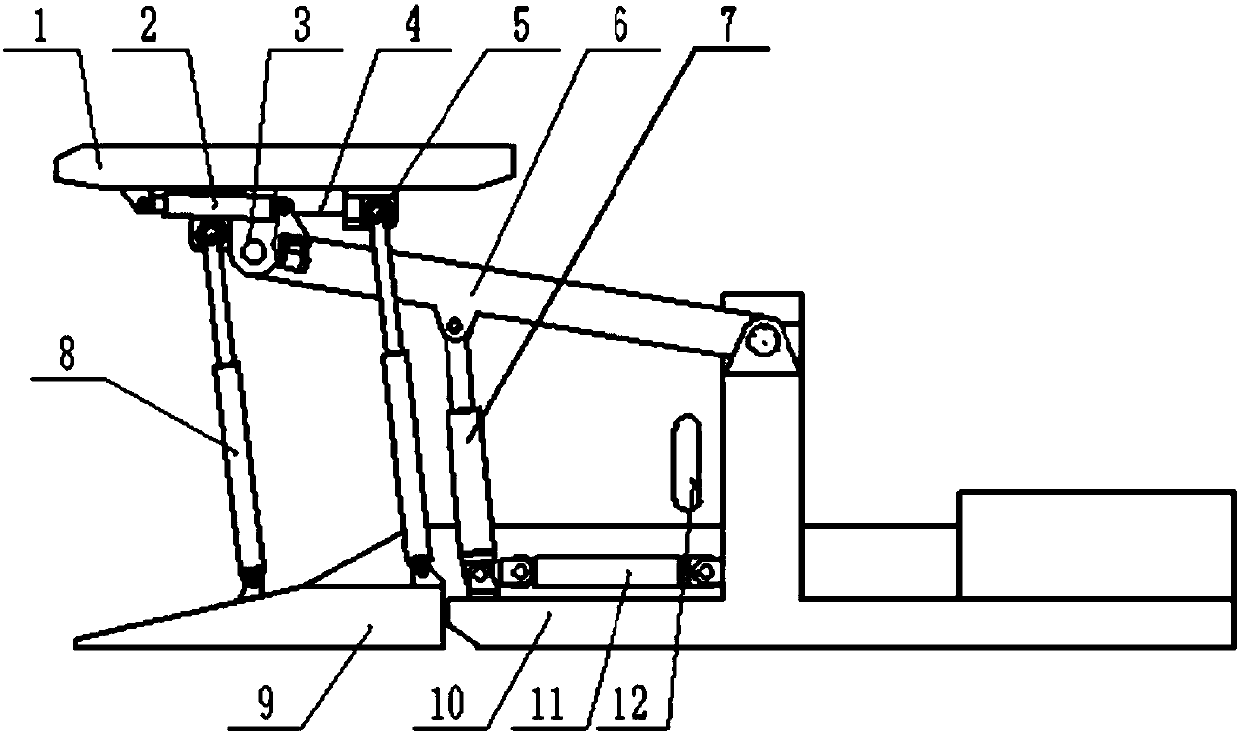

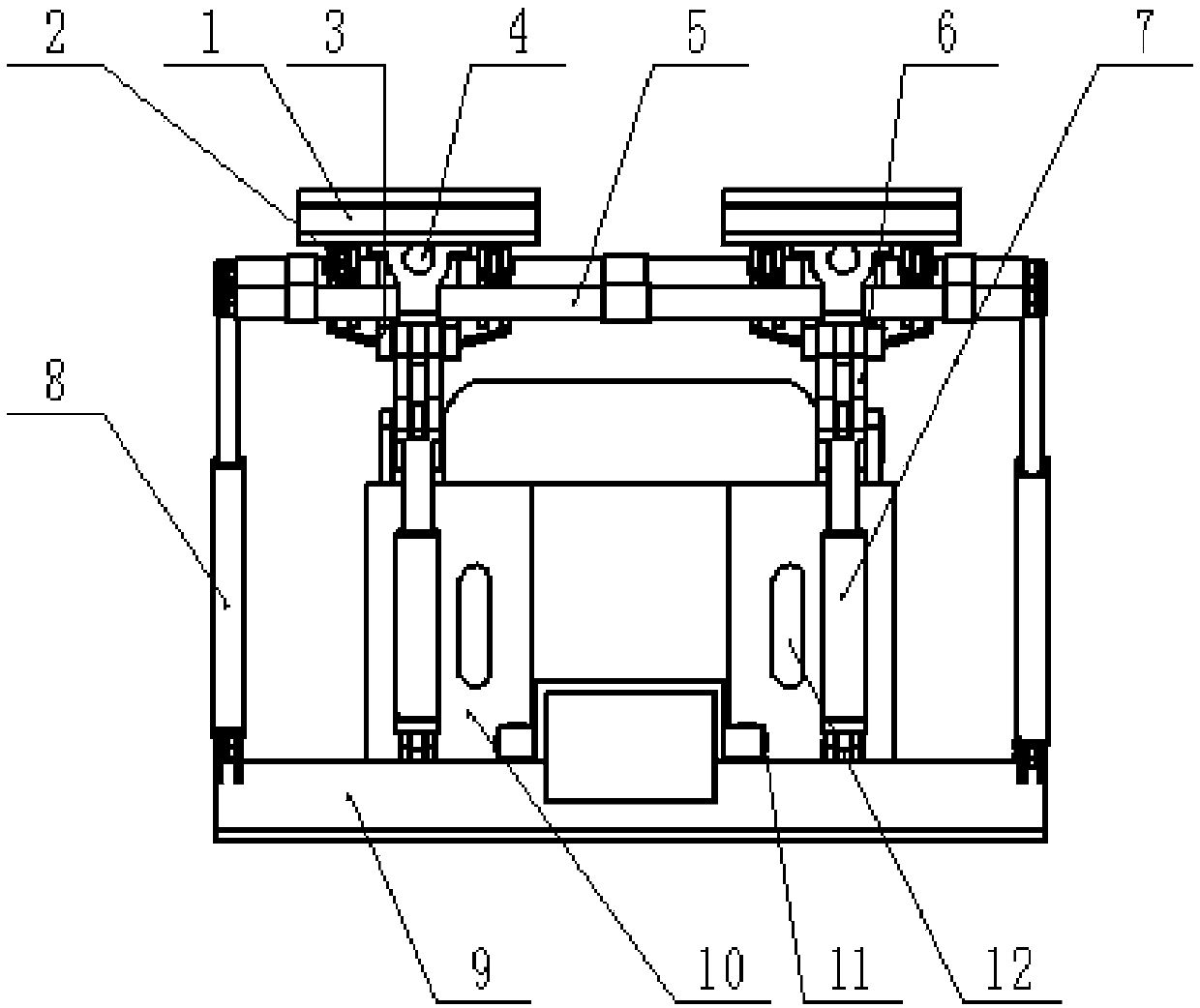

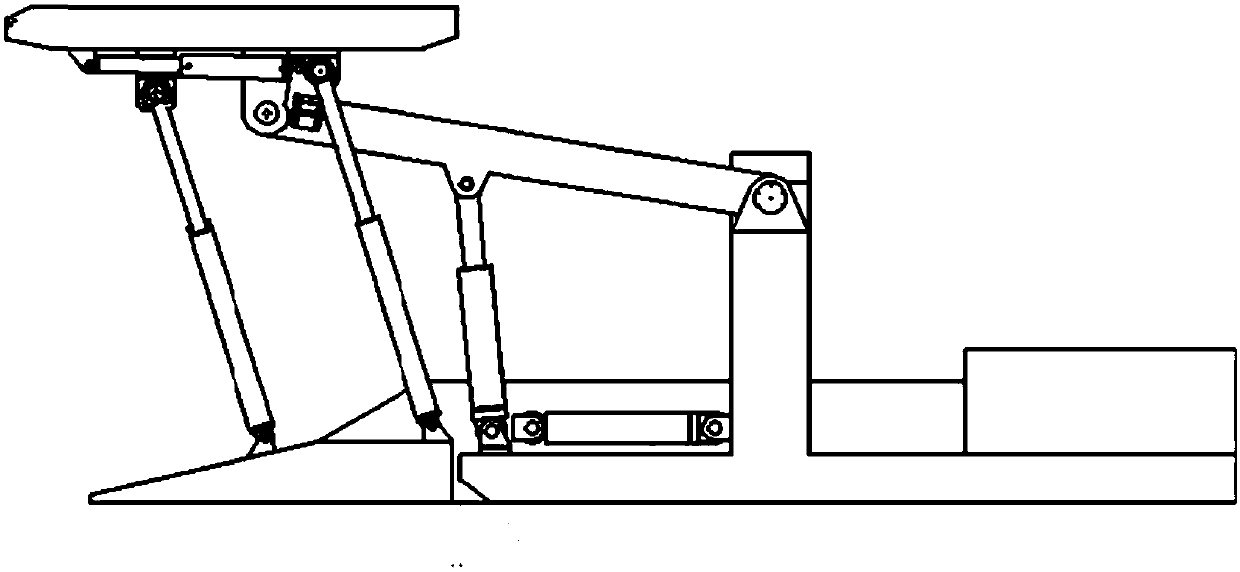

[0029] Such as figure 1 , 2 As shown, the walking support for the mine excavation face of the present invention includes a top beam 1, an upper push jack 2, a friction pair structure that can slide back and forth relative to each other, a single swing rod 6, a rear support column 7, a front support column 8, a shovel Material plate 9, base 10 and down move jack 11.

[0030] The top beam 1 is connected to one end of the single swing link 6 through a friction pair structure that can slide back and forth relatively, the other end of the single swing link 6 is hinged to the base 10, and the rear support column 7 is connected between the base 10 and the single swing link 6; The support column 8 is connected between the shovel plate 9 and the top beam 1; the top beam 1 acts on the single swing rod 6 through the upward push jack 2; the shovel plate 9 is connected with the base 10 through the downward push jack 11; front and rear support Columns 8 and 7 are both telescopic. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com