Candle convenient to use with insertion plate

A plug-in board and candle technology, applied in the field of daily necessities for lighting, can solve the problems of wax oil accumulation on the candle body, difficult to remove, partial burning of the candle, etc., to avoid affecting the appearance and trouble of removal, and stable transparency , the effect of saving candles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

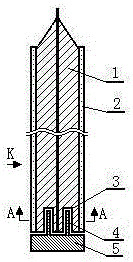

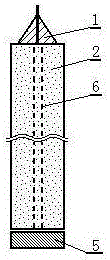

[0016] As shown in the figure, a candle that is convenient to use with a plug board includes a candle body 1. The main features of the present invention are: the outer diameter of the candle body 1 is coated with a layer of transparent polymer fireproof coating 2, transparent polymer Two side-by-side tear lines 6 are arranged along the height direction on the left side wall thickness of the material fireproof coating 2, and the thickness of the transparent polymer fireproof coating 2 is 2mm.

[0017] The lower end of the candle body 1 is provided with three evenly distributed circular concave holes 3 along the axial direction. The concave hole 3 is sleeved on the circular post 4 of the plug board 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com