Automatic feeding and mounting mechanism for inner container of dressing case

An installation mechanism and automatic feeding technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of low efficiency, troublesome to take the inner tank, unsatisfactory effect, etc., and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

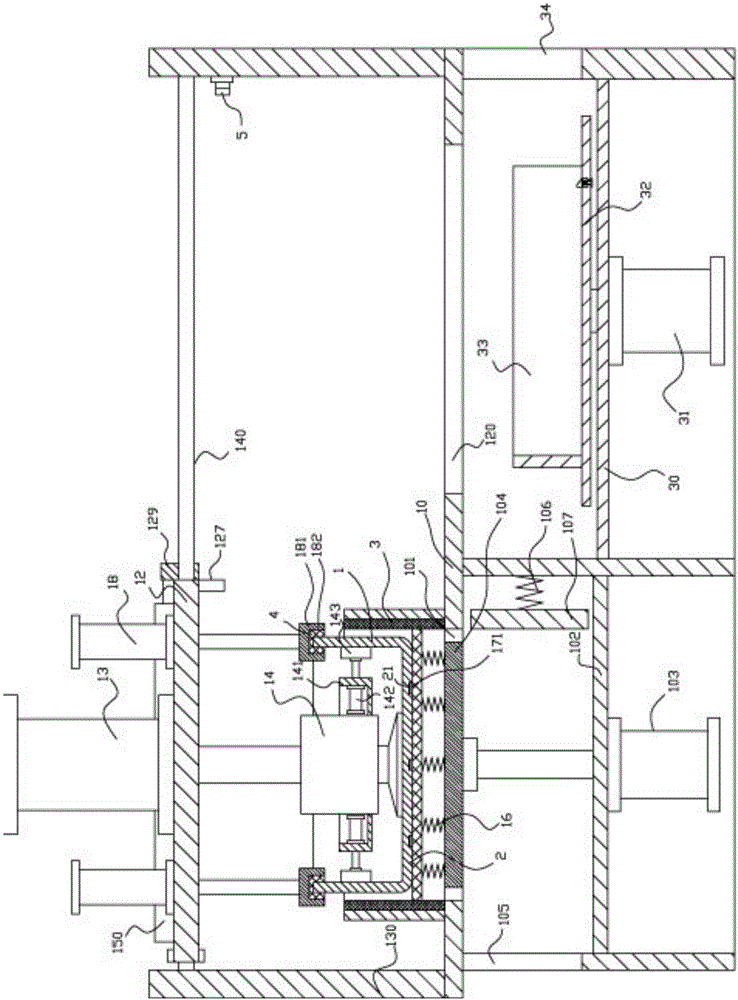

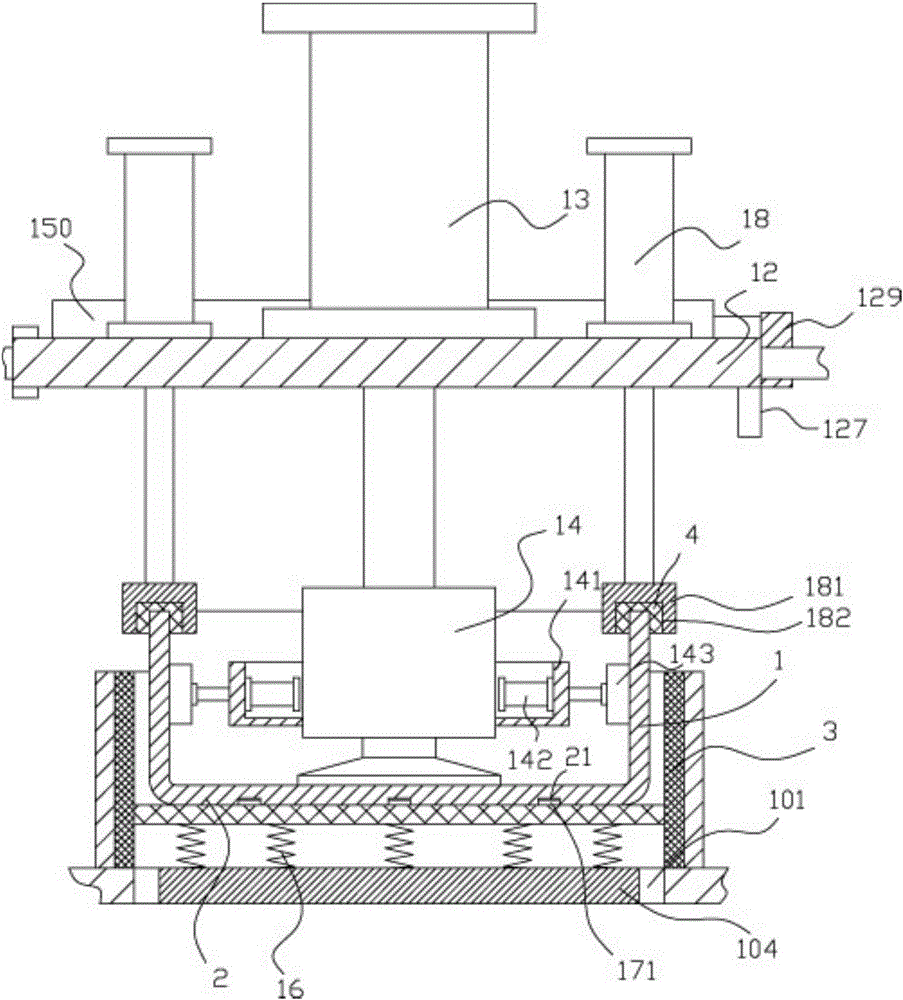

[0022] Example: see Figure 1 to Figure 4 Shown, a kind of makeup box liner automatic feeding installation mechanism, comprises frame 10, the left middle part of the top plate of described frame 10 has through hole 101, and the right middle part of the top plate of frame 10 has grasping through hole 120, the bottom of the grasping through hole 120 is provided with a liner lifting support plate 30, the liner lifting support plate 30 is fixed on the bottom support side plate of the frame 10, and the bottom surface of the liner lifting support plate 30 is fixed with a liner lifting cylinder 31, the push rod of the inner tank lifting cylinder 31 passes through the inner tank lifting support plate 31 vertically upwards and is fixed with the inner tank lifting plate 32, the top surface of the inner tank lifting plate 32 has an annular limit side plate 33, and the frame 10 The bottom support side plate on the right side has a liner feeding through hole 34, which corresponds to the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com