A high-speed alignment mechanism for small cartons

A technology of sorting mechanism and carton, applied in conveyors, conveyor objects, rotary conveyors, etc., can solve the problems of increased labor costs, slow speed, and high error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

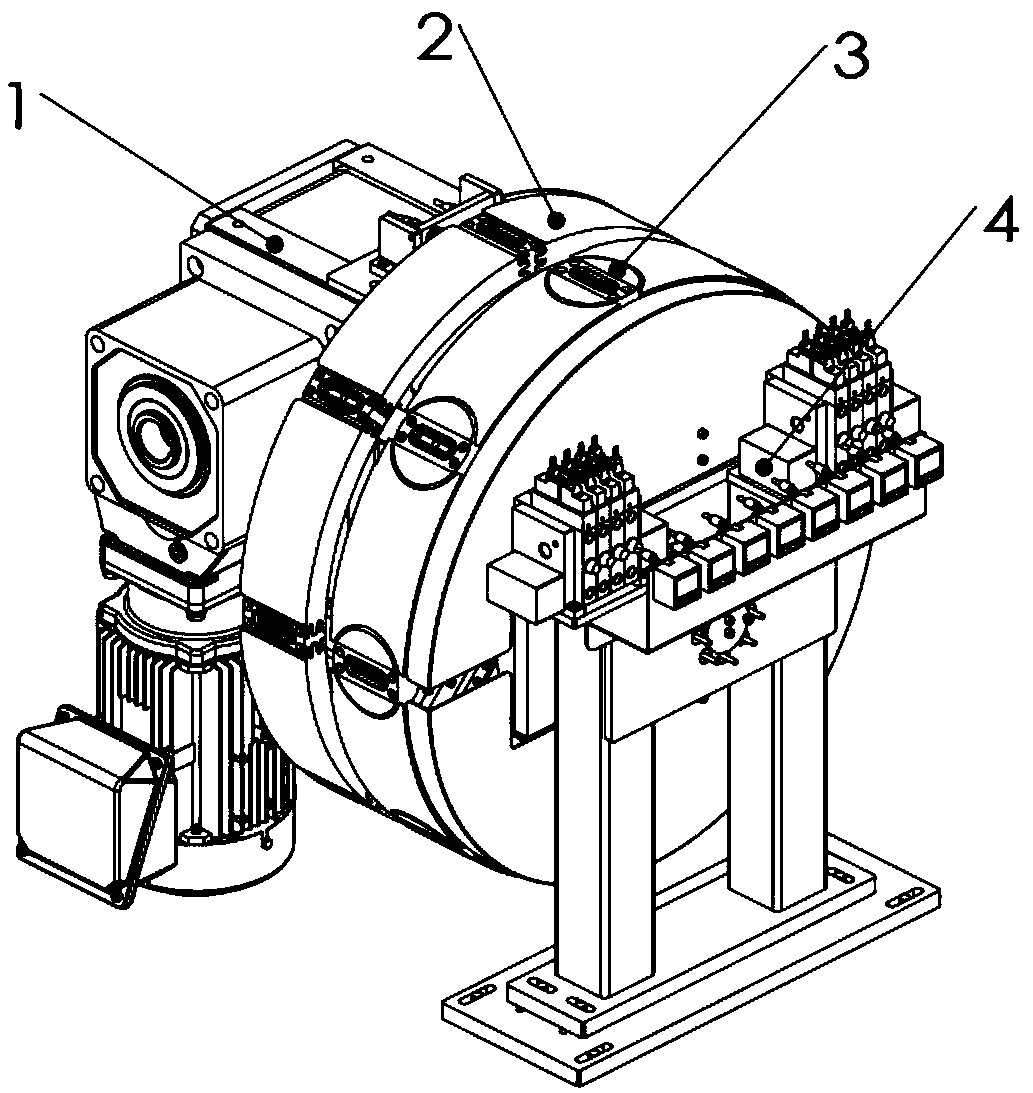

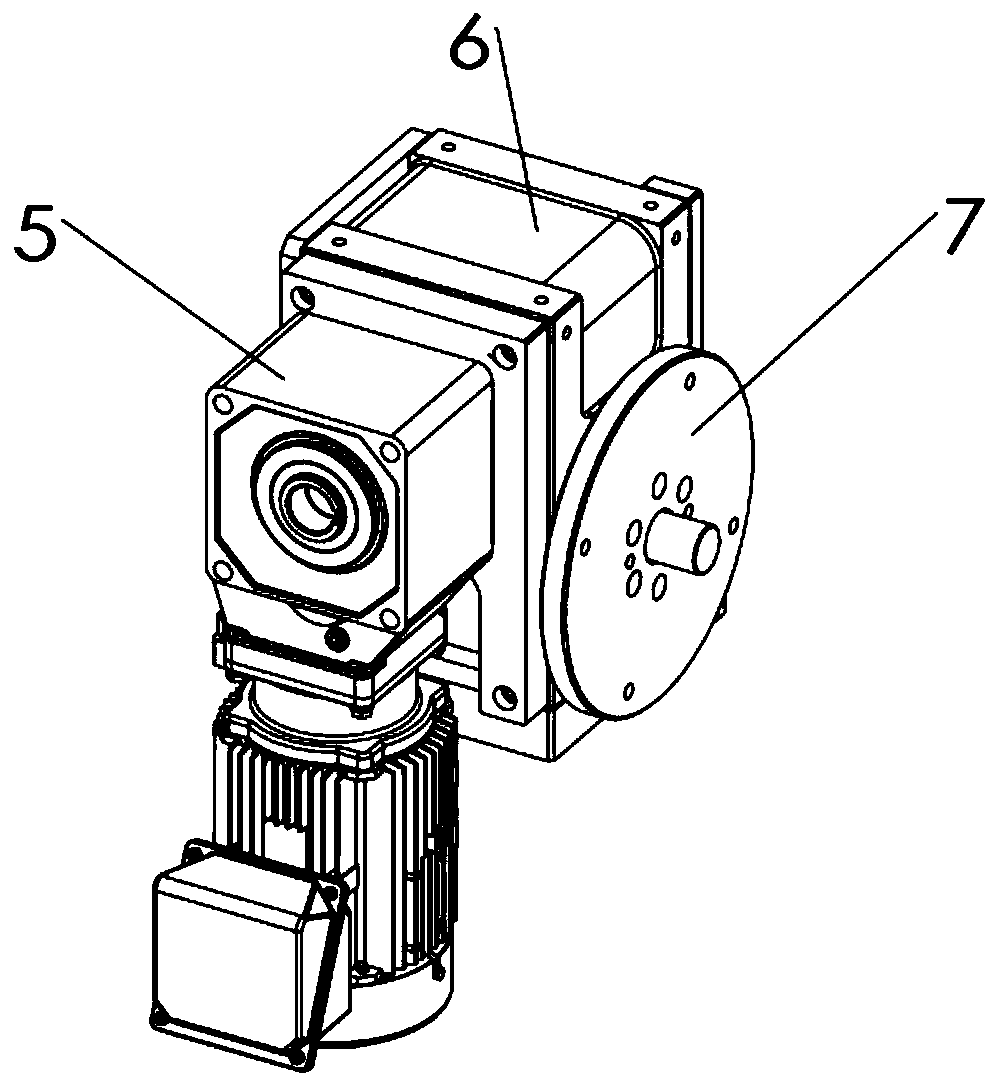

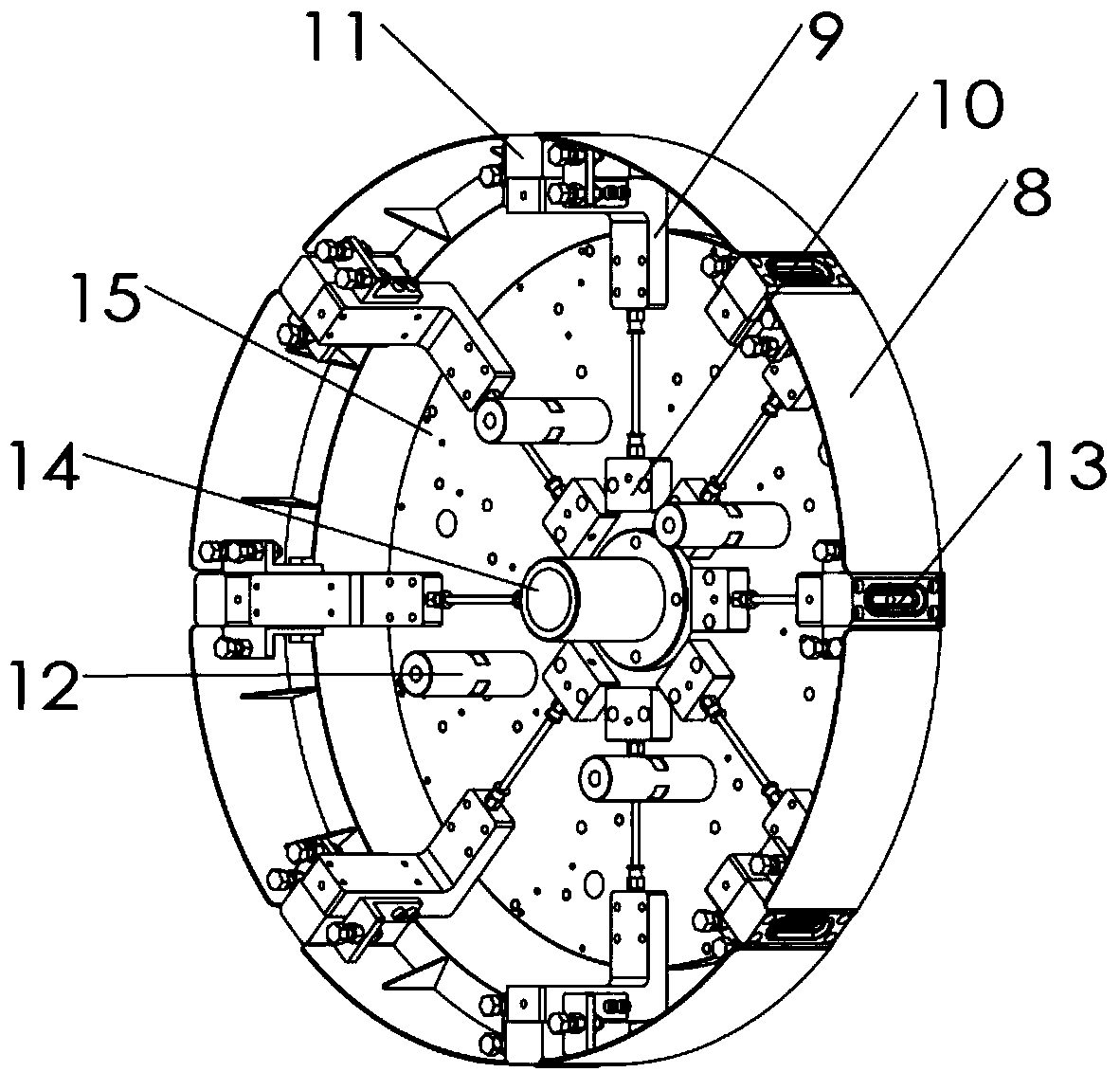

[0027] see figure 1 and Figure 8 , the present invention provides a high-speed sorting mechanism for small cartons, including a divider drive mechanism 1, a static carrier turntable assembly 2, a moving carrier cam assembly 3, a vacuum and frame assembly 4, a front streamline 50 and The streamline 51 in the rear segment.

[0028] The divider driving mechanism 1 is installed and connected with the static carrier turntable assembly 2 .

[0029] The static carrier turntable assembly 2 and the moving carrier cam assembly 3 are installed on the front and rear of the turntable 15 respectively.

[0030] The vacuum and frame assembly 4 is installed and fixed with the moving carrier cam assembly 3 through fastening screws, and communicated through pipelines.

[0031] The divider driving mechanism 1 drives the static carrier turntable assembly 2 and the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com