A multifunctional catenary operation trolley and its operation method

A workbench and catenary technology, applied in the direction of transporting passenger cars, track contact elements, railway car body parts, etc., can solve the problems of inflexible operation, high maintenance cost, incomplete functions, etc., and achieve increased working range and easy operation. , full-featured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

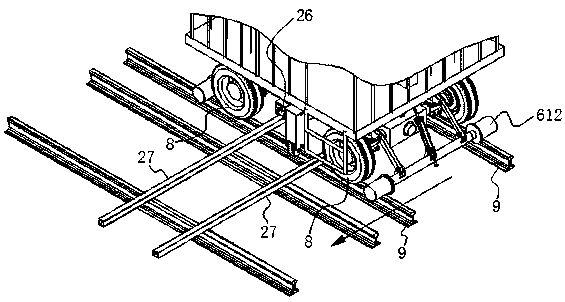

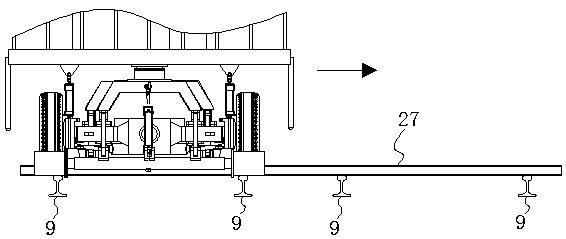

[0050] Embodiment 1: as Figure 1 to Figure 3 As shown, a multifunctional catenary operation trolley includes a front axle 1, a rear axle 2 and a working platform 3, and the front axle 1 and the rear axle 2 are connected together by an underframe 4, and the underframe 4 and located on the side of the front axle 1 is provided with a guide wheel support mechanism 1, on the underframe 4 and located on the side of the rear axle 2 is provided with a guide wheel support mechanism 2 6, the working platform 3 and the underframe 4 They are connected together by a leveling mechanism. The leveling mechanism is used to adjust the levelness of the working platform 3 during operation or walking. The telescopic rotating operating arm 7 is also arranged on the working platform 3, and the bottom frame 4 is provided with a preventive Anti-overturning mechanism for overturning during operation or walking. A hydraulic power system (not shown in the figure) is also provided on the underframe 4, a...

Embodiment 2

[0084] Embodiment 2: as Figure 12 and Figure 13 As shown, compared with Embodiment 1, the difference is that the anti-overturning device is a roller mechanism 28, and the roller mechanism 28 includes a left roller 281, a right roller 282, and an L-shaped connecting rod 283 hinged on the chassis 4. , the L-type connecting rod two 284 and the roller mechanism oil cylinder 285 hinged on the underframe 4; the left roller 281 is rotatably connected to one end of the L-type connecting rod 283, and the right roller 282 is rotatably connected to one end of the L-type connecting rod 284 On, one end of the roller mechanism oil cylinder 285 is hinged with the other end of the L-shaped connecting rod 283, and the other end of the roller mechanism oil cylinder 285 is hinged with the other end of the L-shaped connecting rod 284; the left roller 281 and the right roller 282 are located on two The position between the steel rails 9 and the left roller 281 is in contact with the side of a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com