Automobile seat sliding track assembling machine, clamping mechanism thereof and adjusting method

A technology for a slide rail and a clamping mechanism for an automobile seat, which is applied in the field of automobile manufacturing, can solve the problems of difficulty in adjusting the strength, the quality of the finished slide rail device is average, and there is no inner slide rail and a cage to increase the clamping force, so as to ensure the assembly. quality, the effect of increasing the gripping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

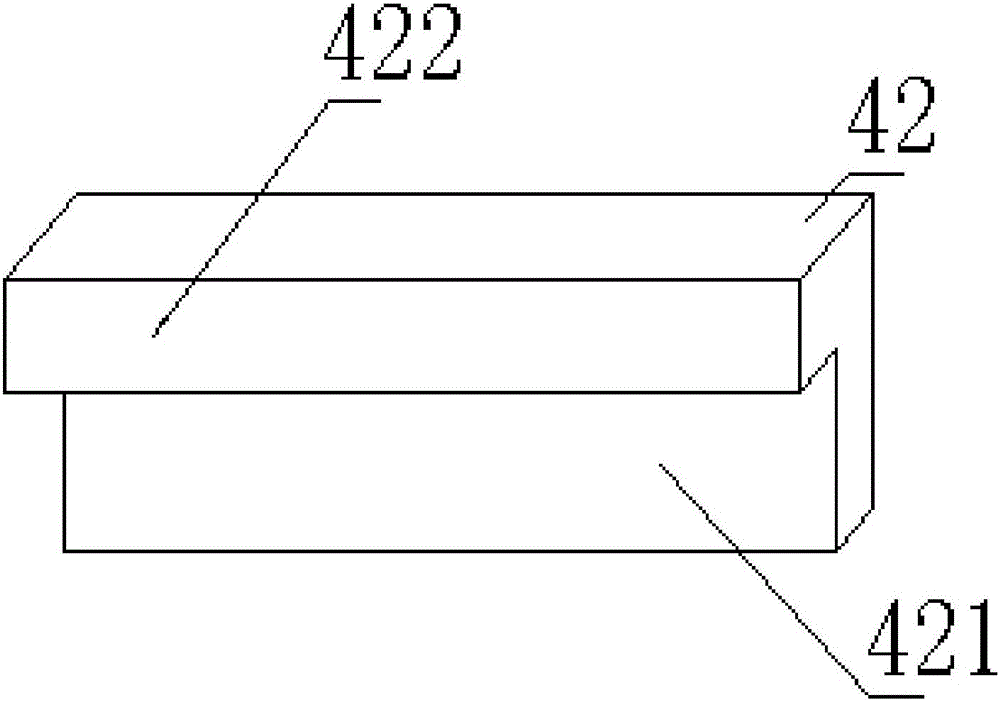

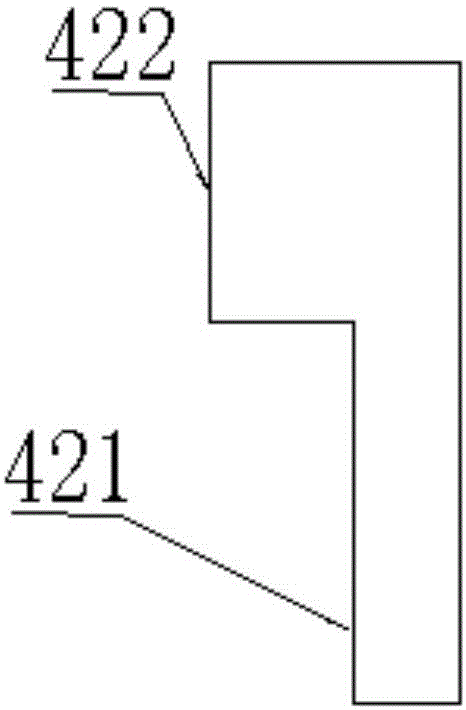

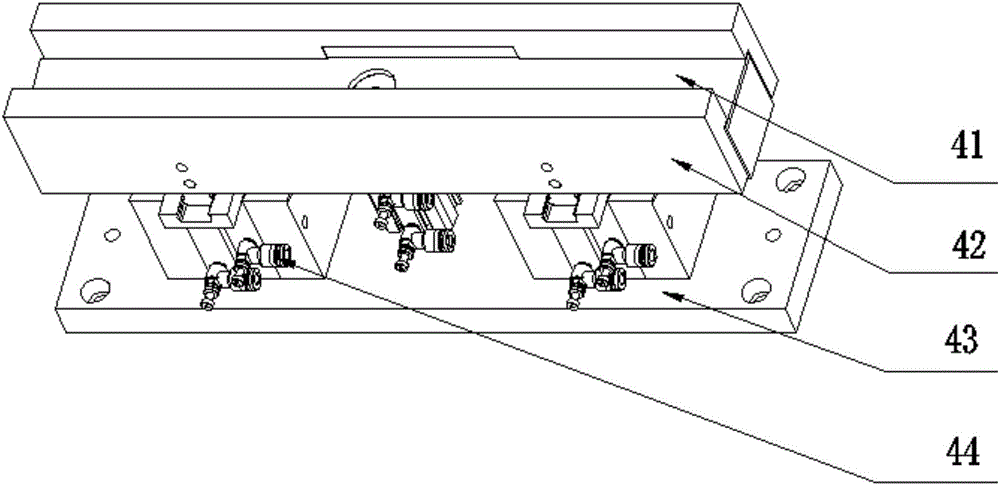

[0033] Such as figure 1 , figure 2 with image 3 As shown, the clamping mechanism 4 of the present invention includes a clamping support base 41, a clamping movable clamping plate 42, a fixed bottom plate 43, and a clamping finger cylinder 44. The two clamping movable clamping plates 42 are respectively arranged on the clamping support On both sides of the seat 41, two clamping finger cylinders 44 are respectively fixed on the fixed base plate 43, and the two clamping finger cylinders 44 are respectively connected to two clamping movable clamping plates 42, so that the state of the two clamping finger cylinders 44 can be controlled. Opening and closing between the two clamping movable clamping plates 42 is controlled. In the open state, place the two cages next to the two clamping movable clamping plates 42 respectively, and then place the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com