A ball cage positioning device

A technology of positioning device and ball cage, which is applied in positioning device, workpiece clamping device, clamping and other directions, can solve the problems of high operator skill requirements, unfavorable fixture positioning, and manual operation can not meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific examples of the present invention to further describe the technical solutions of the present invention, but the present invention is not limited to these examples.

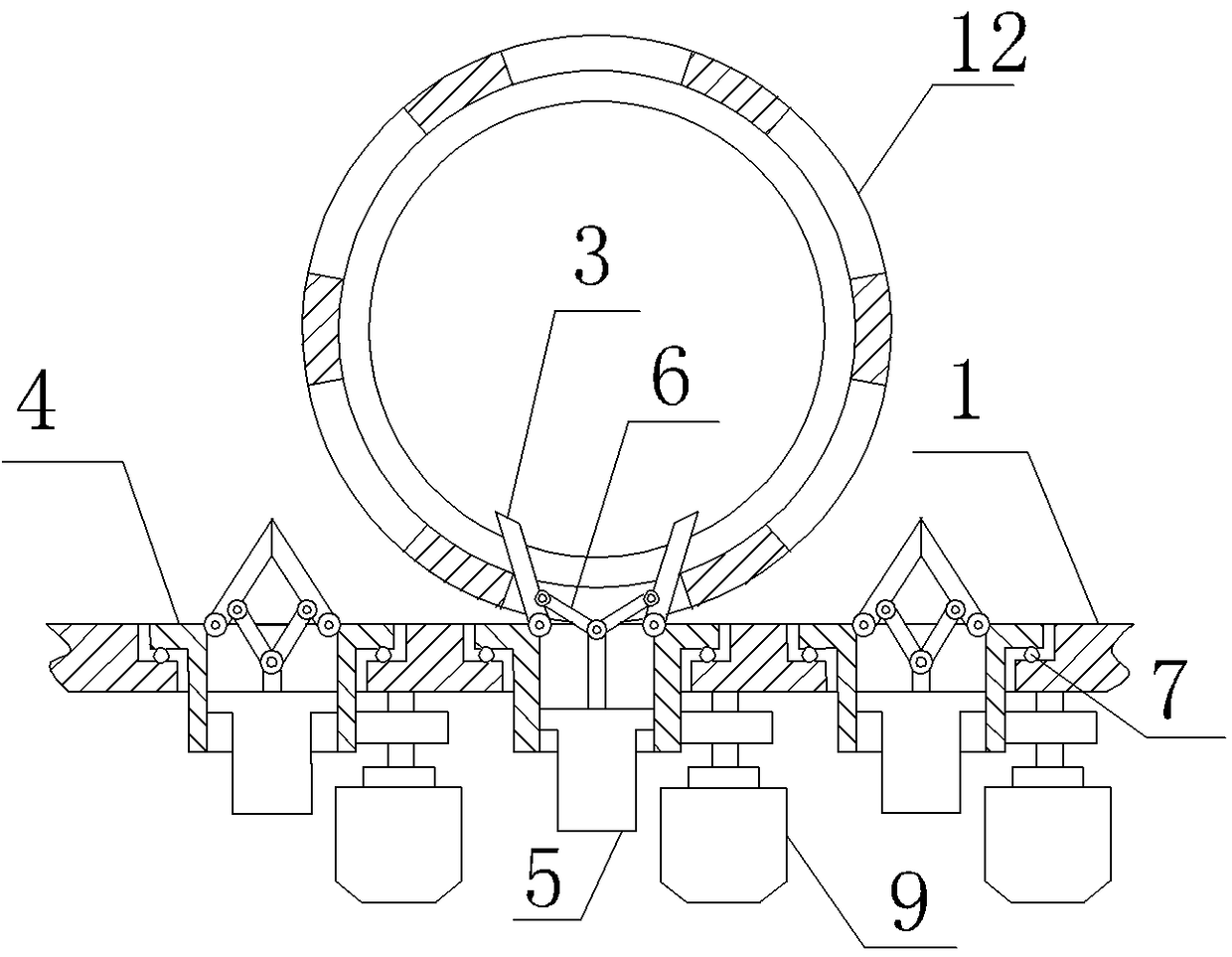

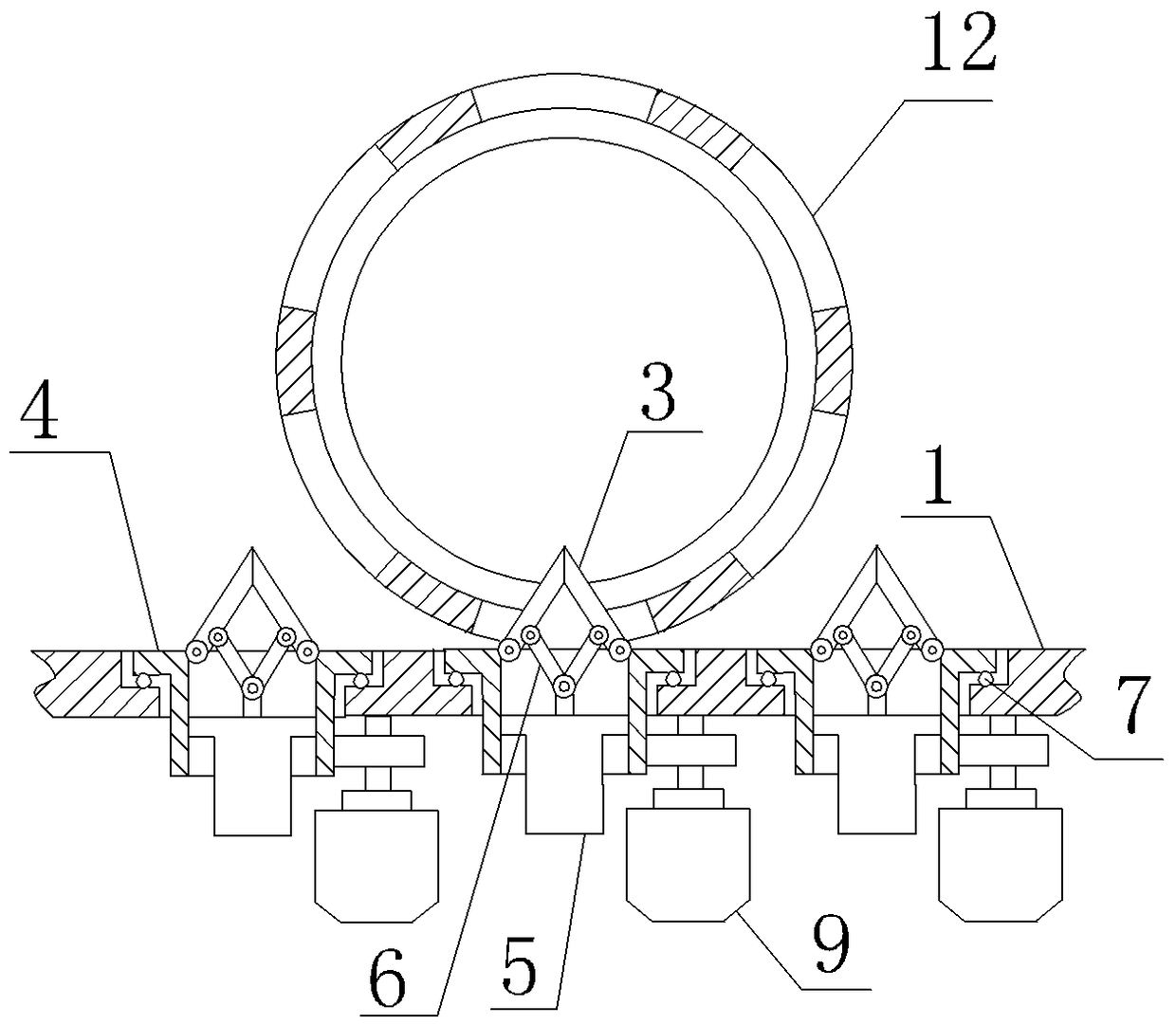

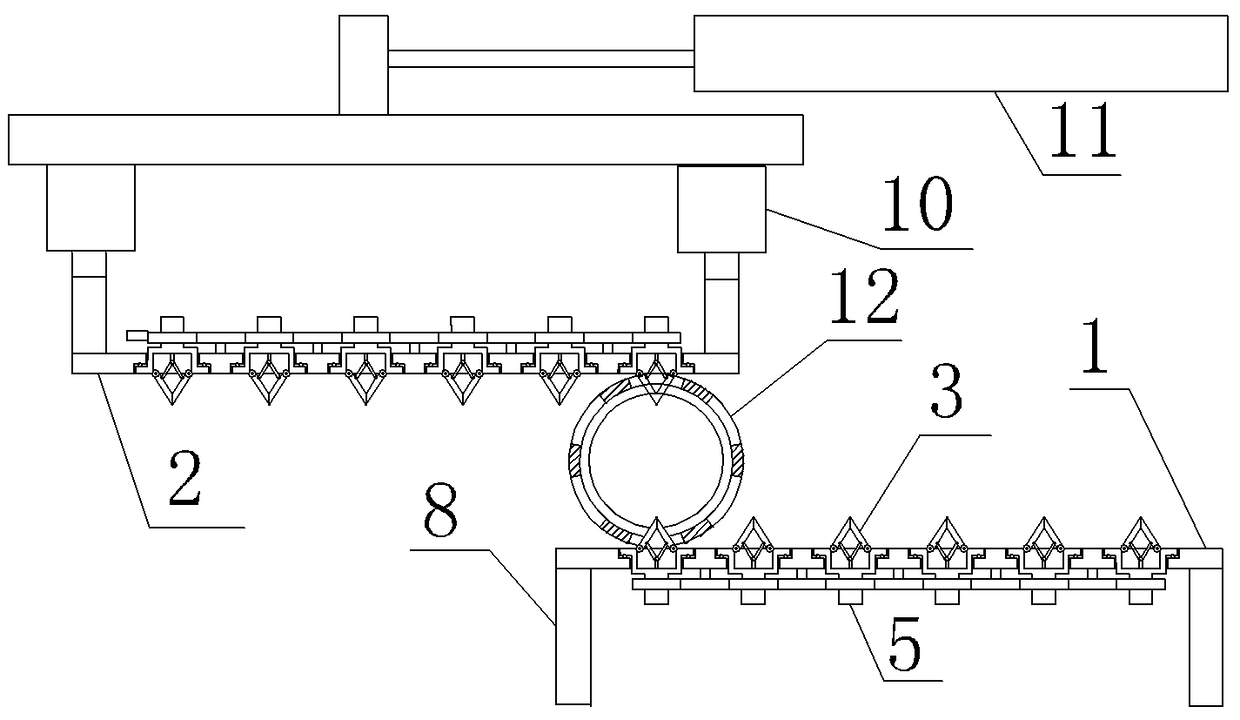

[0020] As shown in the figure, a ball cage positioning device includes a lower guide plate 1 and an upper guide plate 2 for supporting and guiding the ball cage. Six ball cage azimuth controllers are arranged along the length direction of the guide plate, and the spacing between the ball cage azimuth controllers is equal to the circumferential spacing of the 12 cage windows. The cage orientation controller includes two opening and closing plates 3 that can extend into the window of the ball cage. The bottom ends of the two opening and closing plates are connected to the rotating drum 4 through column hinges, and the rotating drum axis is perpendicular to the guide plate. Two opening and closing plates are arranged opposite to each other in the length direction of the guide plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com