Pressing stirring type cup

A stirring and cup technology, which is applied to household appliances, applications, kitchen utensils, etc., can solve the problems that the force direction is difficult to accurately predict, and the force area of the stirring cup is large, so as to achieve the effect of not easy to tip over and even distribution of the center of gravity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

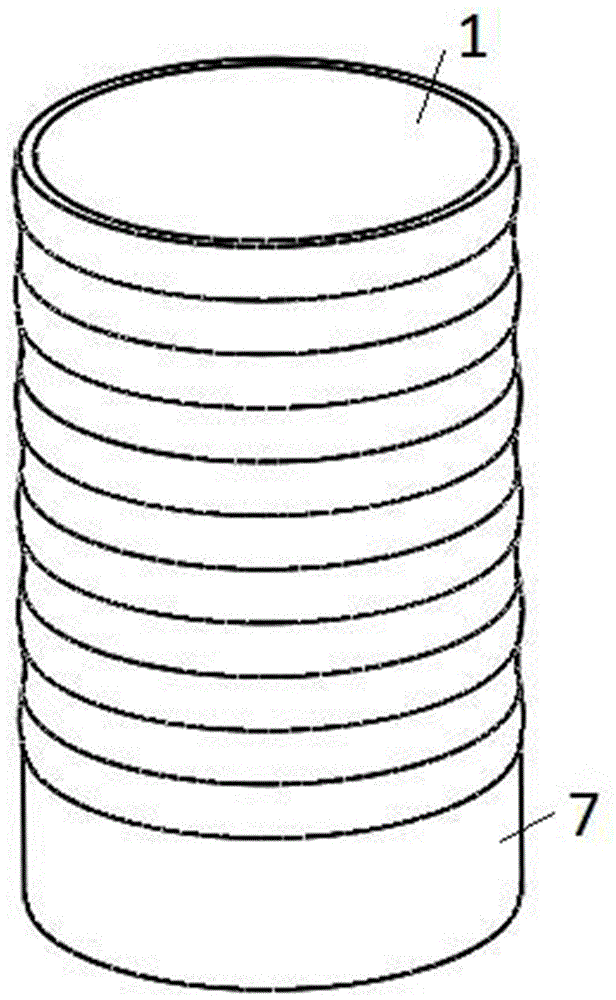

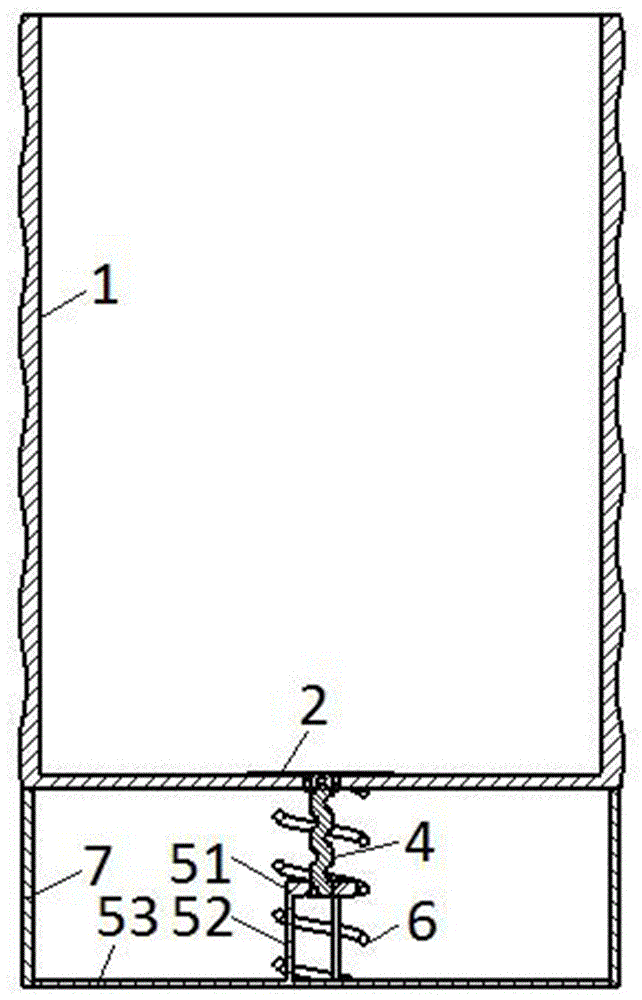

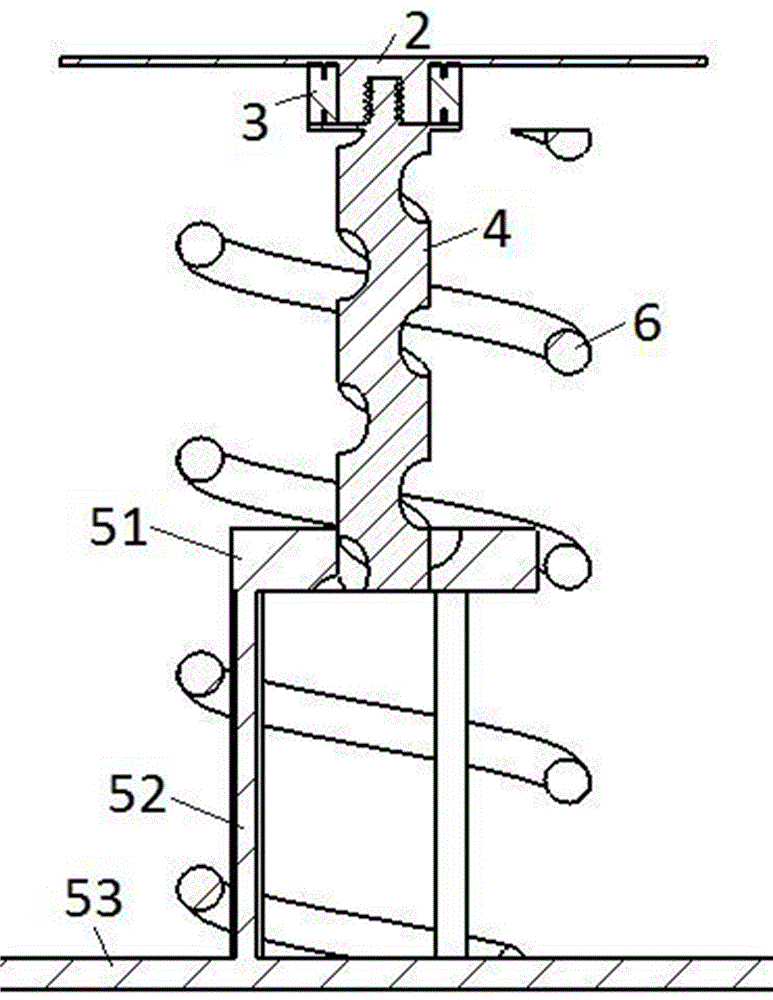

[0043] The user puts liquid material into the container 1 of the mixing cup, holds the wave-shaped outer wall of the container 1 and presses the container 1 downward, and the screw shaft 4 is driven by manpower to slide down in the through hole of the top plate 51, and the screw shaft 4 4 Rotate and drive the connected paddle 2 to rotate to stir the material in the container 1. When the lower end of the screw shaft 4 touches the column gasket 5, the container 1 can no longer be pressed down. The user lets go of the hand, and the compressed cylinder When the spring and soft cover return to their original shape, the container part 1 is pushed upward by elastic force, and the screw shaft 4 is driven by the elastic force to slide upward in the through hole of the top plate 51, and the screw shaft 4 rotates in the opposite direction and drives the wheel paddle 2 connected to it to rotate. Stir the material in the container part 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com