Engine control system

一种控制装置、发动机的技术,应用在发动机控制、自动控制、自动控制等方向,能够解决燃烧变动或偏差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

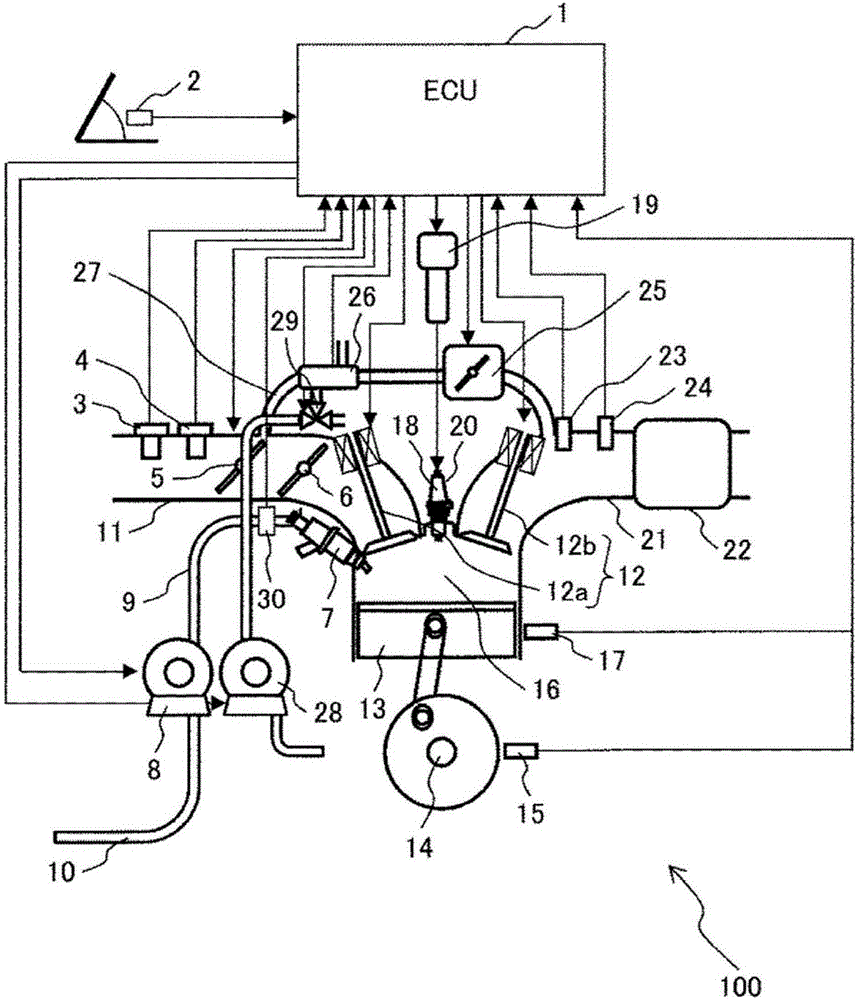

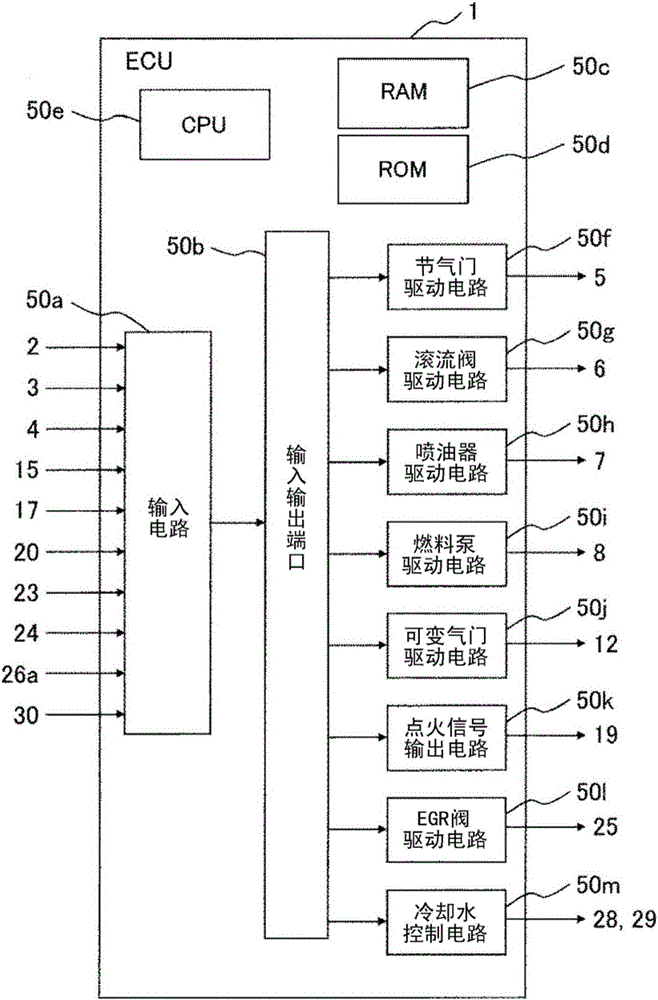

[0046] Next, use Figure 1 to Figure 13 , the configuration and operation of the engine control device according to the present embodiment will be described.

[0047] Figure 1 to Figure 13According to one embodiment of the present invention, it is a configuration diagram of a system in which an engine control device is applied to a gasoline engine for an automobile. device and a recirculation device for recirculating the exhaust gas toward the intake side, in the engine control device, the temperature of the exhaust gas recirculated by the recirculation device is higher than that of the lower case, or the exhaust gas is recirculated by the recirculation device When the amount of exhaust gas is larger than when the amount of exhaust gas is smaller, perform at least one of the following operations, that is, advance the fuel injection timing of the injection device, increase the fuel pressure supplied to the injection device, The number of split multi-stage injections performe...

Embodiment 2

[0093] Next, use Figure 14 , Figure 15, Figure 16, Figure 17, Figure 18, Figure 19 , the second embodiment of the present invention will be described. In this example, use figure 1 The system described in is used as an automotive engine system. Additionally, use figure 2 The configuration described in hereinafter is used as the ECU 1 .

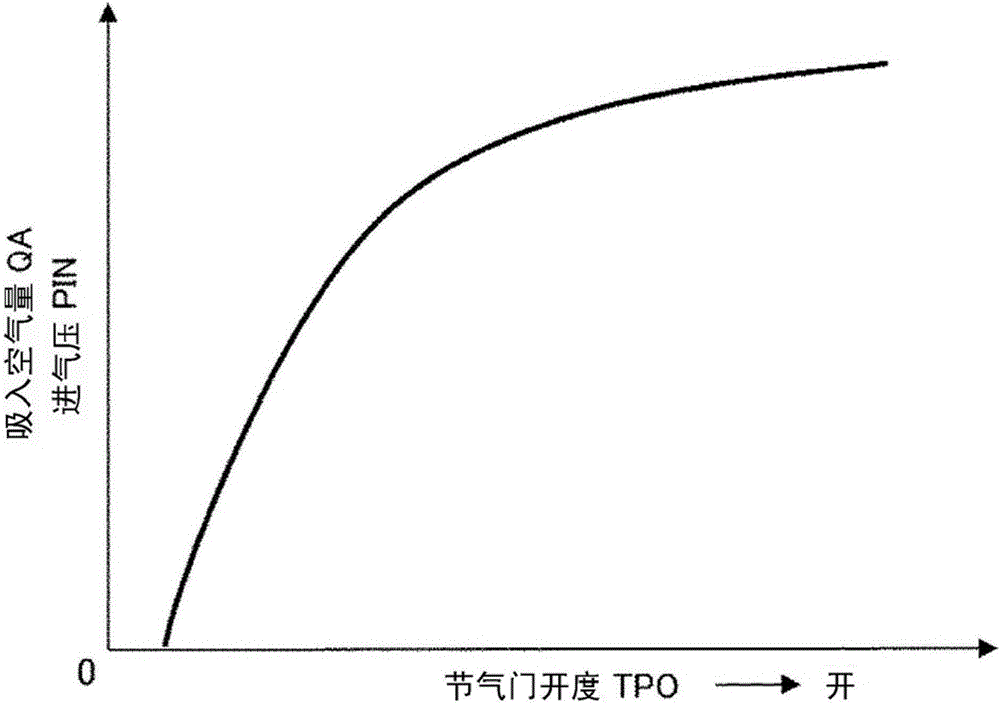

[0094] Figure 14 Regarding the present embodiment, it is a characteristic map of EGR control based on the intake air amount QA and the engine speed NE. The vertical axis represents the intake air amount QA, and the horizontal axis represents the engine speed NE. The EGR control determines the ranges of internal EGR, external EGR, and without EGR (without EGR) based on the intake air amount QA and the engine speed NE. At this time, the internal EGR controls the EGR flow through the variable intake and exhaust valves 12 . External EGR controls EGR flow through EGR valve 25 .

[0095] Figure 15A It is a characteristic diagram showi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com