Nested giant magnetostrictive actuator

A giant magnetostrictive and actuator technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problem of increasing the output displacement of giant magnetostrictive actuators, etc. problem, to achieve the effect of simple structure, increased output displacement, and large output displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

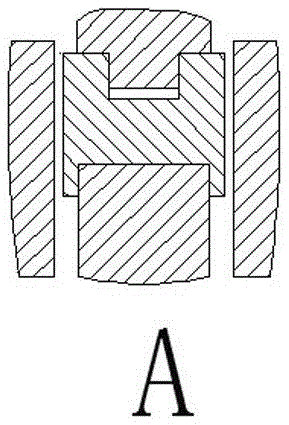

[0019] The invention utilizes the magnetostrictive effect characteristic of the magnetostrictive material, and designs a nested giant magnetostrictive actuator by combining two kinds of magnetostrictive materials with different shapes.

[0020] The nested giant magnetostrictive actuator mainly includes a magnetic-resistance base, a lower magnetic-conductive sheet, a coil bobbin, a magnetostrictive sleeve, a magnetic-conductive sleeve, a magnetic-resistant sleeve, a lower magnetic-conductive block, and a magnetostrictive rod , upper magnetic block, cylindrical yoke, upper magnetic sheet, magnetic resistance shell, magnetic resistance step transmission shaft, preload cover and disc spring, such as figure 1 As shown in , the lower end of the giant magnetostrictive actuator has an inner groove at the bottom, a bolt through hole on the circumference, a ring-shaped boss on the outer edge of the upper end, and a magnetic resistance base 7 with a boss in the center; There is a boss in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com