Self-ventilation motor highly efficient in cooling and heat dissipation

A self-ventilating, high-efficiency technology, applied in the direction of cooling/ventilating devices, electrical components, electromechanical devices, etc., can solve the problems that the self-ventilating motor cannot meet the performance requirements of the motor, and reduce the cost of the vehicle and the space of the vehicle body. Uniform heat dissipation and improved cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

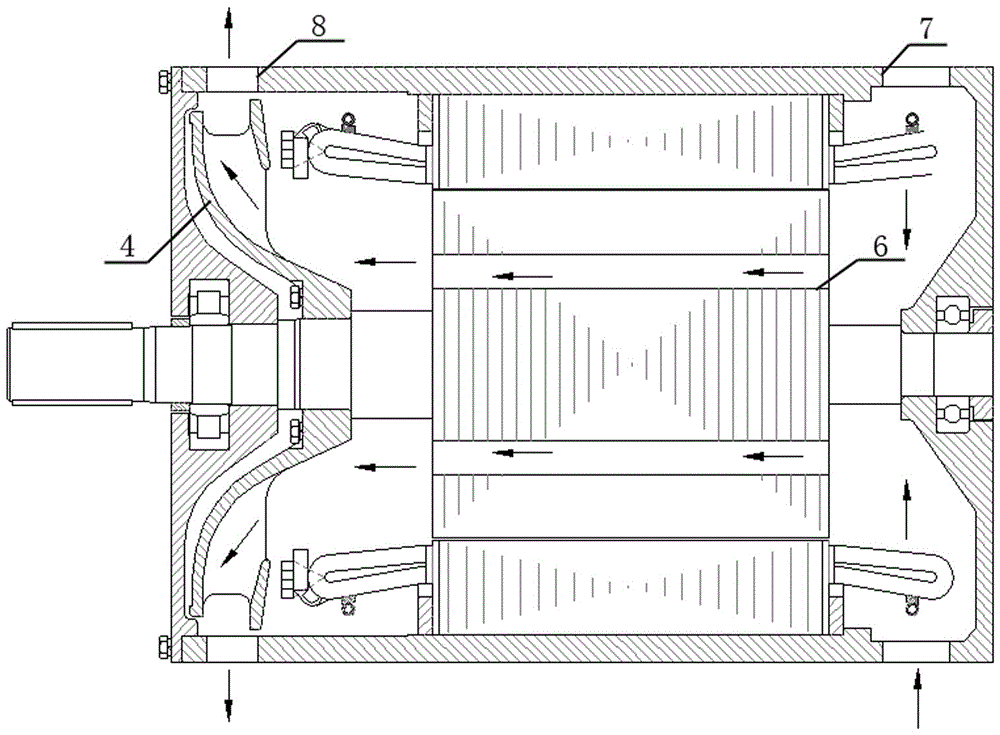

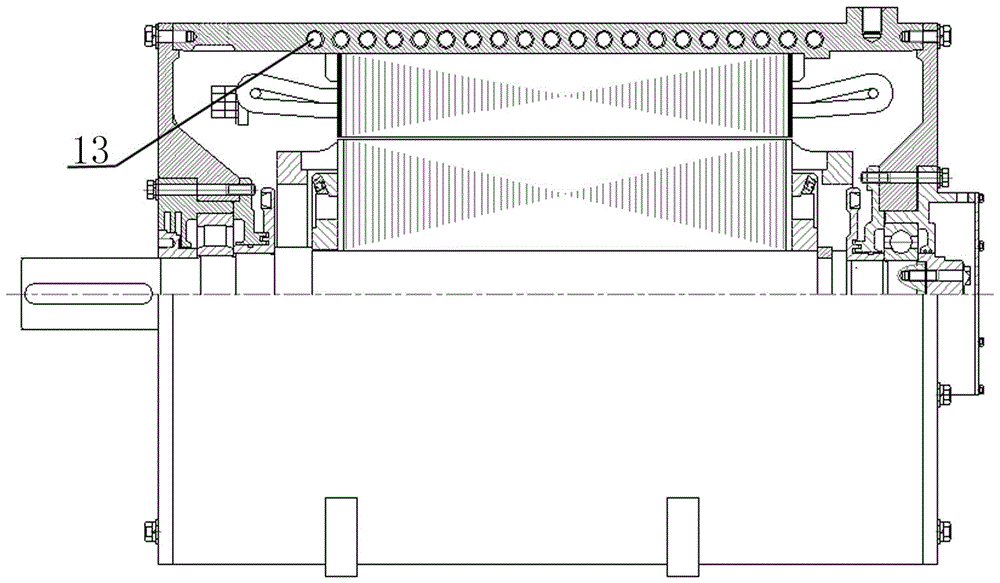

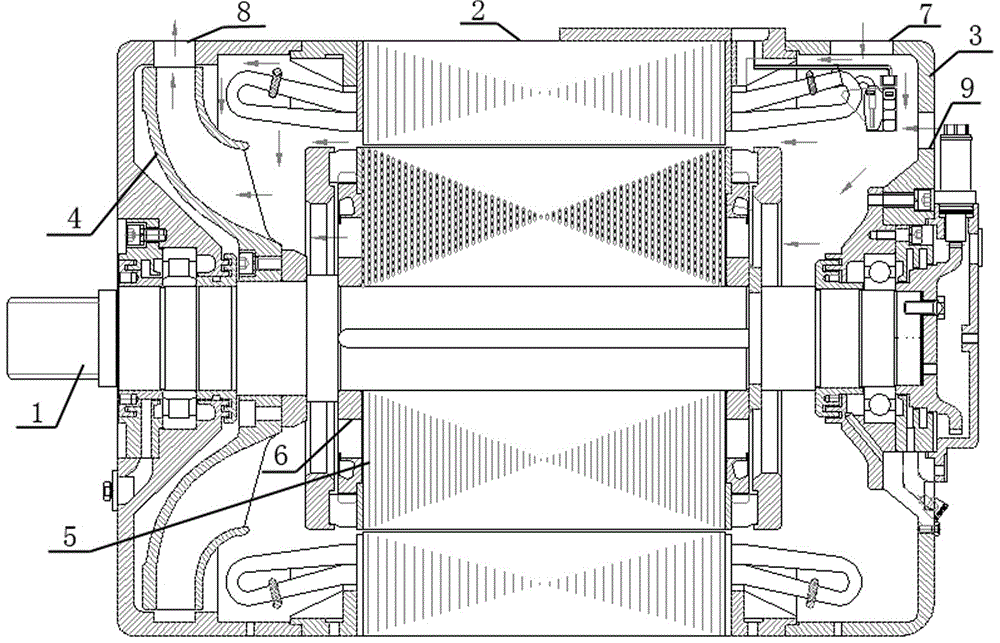

[0018] A self-ventilated motor with high-efficiency cooling and heat dissipation, including a rotor, a frame 2, and an end cover 3, wherein the rotor includes a rotating shaft 1, a centrifugal fan 4, and a rotor core 5, the rotor core is provided with axial ventilation holes 6, and the frame includes a stator core 10 and the casing 11, the casing 11 is provided with an outer circular air inlet 7 and an outer circular air outlet 8, the end cover is provided with an air inlet 9, the stator core 10 is fixed on the casing 11 through the rib plate 12, the stator core and the machine There is a ventilation space between the inner walls of the casing, thus forming four air passage structures. The first air passage structure includes the air inlet 7 of the outer circle of the casing, the ventilation space between the stator core and the inner wall of the casing, the centrifugal fan 4 and the outer circle of the casing. The air outlet 8, the second air path structure includes the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com