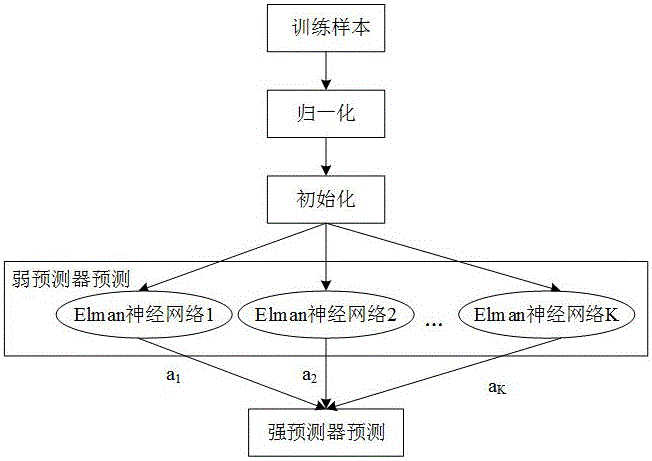

Method for predicting content of silicon in molten iron on basis of Elman-Adaboost strong predictor

A technique for strong predictors, forecasting methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

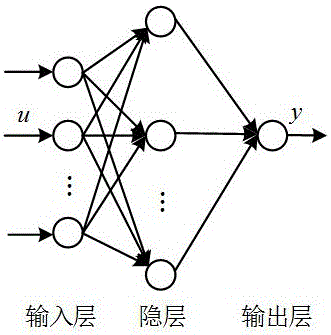

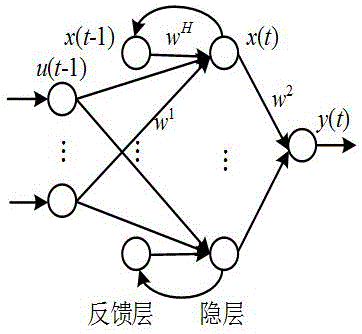

Method used

Image

Examples

Embodiment

[0075] Blast furnace ironmaking is the process of reducing iron ore to iron, which is time-varying, nonlinear, multi-scale and dynamic. The silicon content in molten iron is an important variable that reflects the quality of pig iron and the thermal state of the production process. A high silicon content indicates residual coke in the furnace, and a low silicon content indicates that the energy reserve in the furnace is exhausted. Lower silicon content can not only stabilize the quality of pig iron and save energy, but also avoid hearth freezing when cooling the hearth, so the silicon content should be controlled to fluctuate smoothly within a lower range. However, due to the complex temporal and spatial distribution of variables in the blast furnace and physical and chemical reactions, the high temperature, high pressure and corrosive environment in the blast furnace, and the closedness of the blast furnace structure, it is difficult to directly measure the silicon content in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com