Special pressure head for cylinder hydrostatic test

A hydraulic test and indenter technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems that it is difficult to meet the automatic operation of the automated test production line, the indenter cannot meet the use requirements, and the connection and sealing cannot be realized. , to achieve the effect of reliable sealing, avoid bearing axial force, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

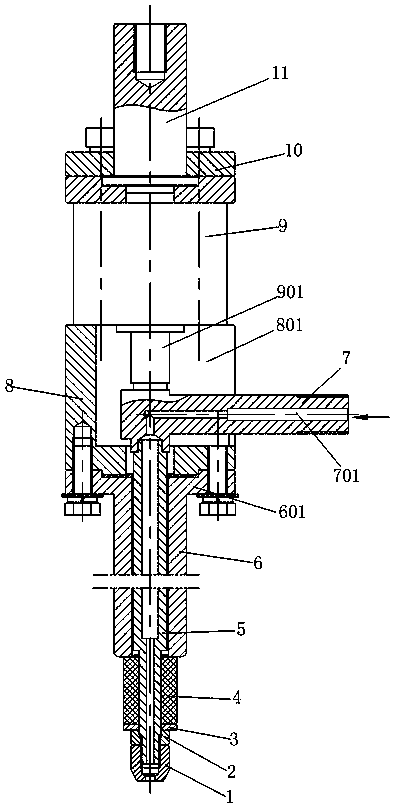

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

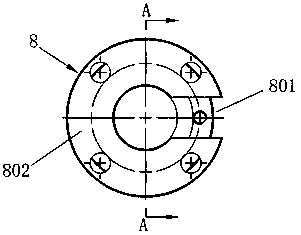

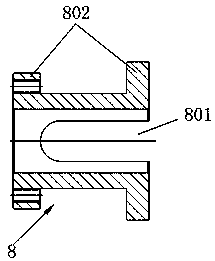

[0015] Such as Figure 1~3 As shown, the present invention includes a hollow tubular central rod 5, the central rod 5 is slidably sleeved in the sleeve 6, the central rod 5 can move up and down in the sleeve 6, the lower end of the central rod 5 is fixedly equipped with a nut 2, an elastic sealing ring 4 And the gasket 3 is set on the center rod 5 between the casing 6 and the nut 2. The elastic sealing ring 4 can be a rubber sealing ring or a silicone sealing ring. A ball nut 1 is provided under the nut 2. The ball nut 1 is used In anti-loosening. The upper end of the casing 6 is provided with a flange 601, and the upper end of the casing 6 is fixedly connected to the lower end of the connecting body 8 by bolts through the flange 601. Connect the upper end of the cylinder body of cylinder 9, connecting rod 11 can conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com