Movable extending-and-contracting control method for electrical equipment support in underground comprehensive pipe gallery

A technology of electrical equipment and control methods, applied in the direction of mechanical equipment, supporting machines, etc., to achieve the effects of stable connection, simple structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

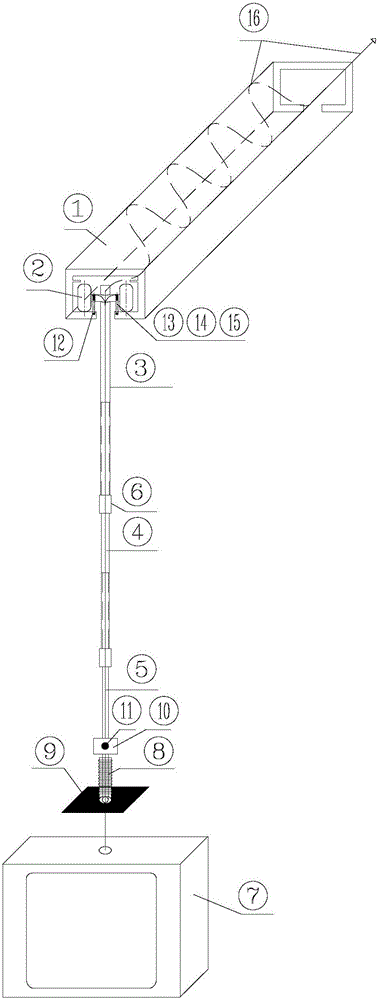

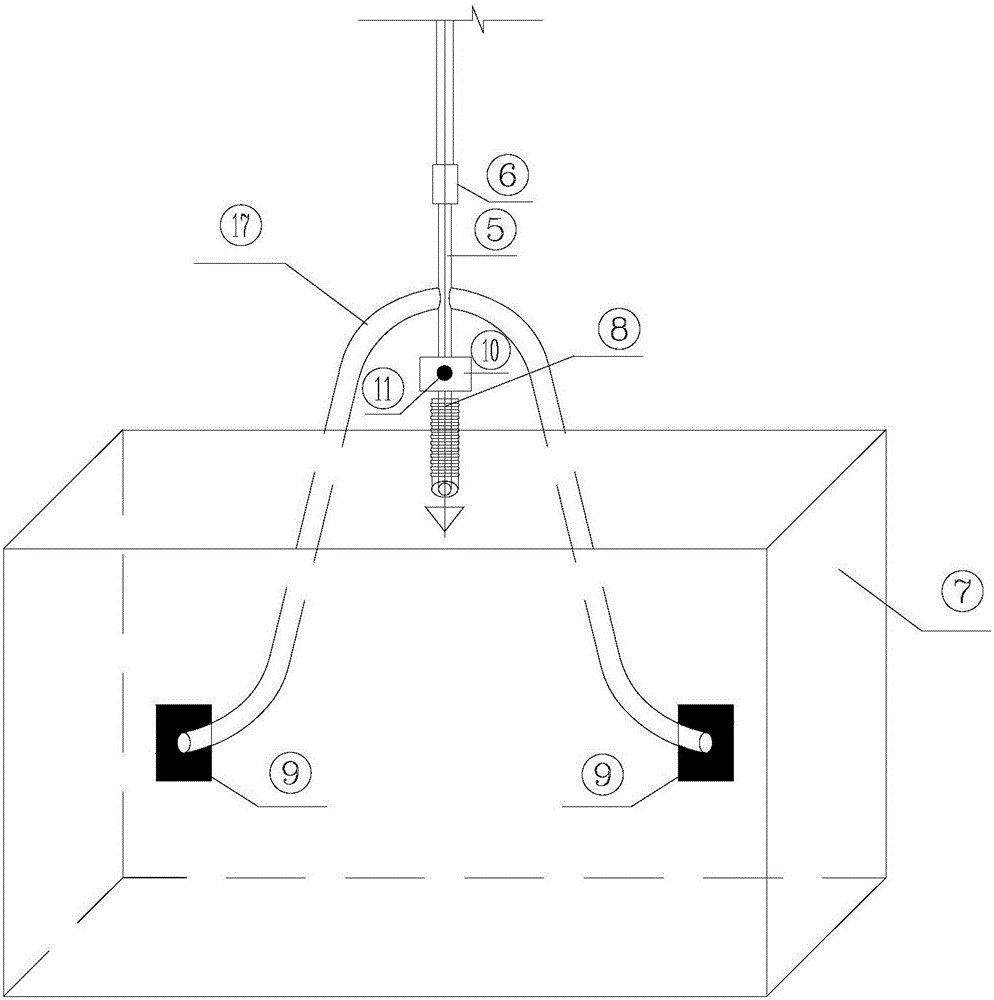

[0042] like figure 1 As shown, the present invention implements a movable and telescopic control method for electrical equipment in an underground comprehensive utility gallery through a movable and telescopic electrical equipment bracket, the electrical equipment bracket including a translation mechanism, a telescopic mechanism, a connection mechanism, and a control unit. Among them, the translation mechanism includes slide rail 1, walking wheel 2, electromagnet 13, spring 14, limit pin 15, etc.; 5 (telescopic rod); the connection mechanism includes a locking sleeve 6, a fixed pin and a hasp; the control unit includes a control box 10, a control button 11, and a cable 16. The bottom of the electrical equipment support is additionally provided with a flexible pipe 8 and a welding plate 9 for connecting the electrical equipment 7 .

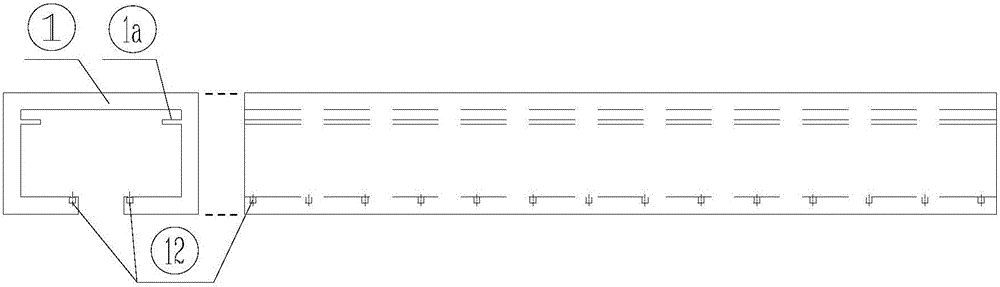

[0043] like image 3As shown, the slide rail 1 of the translation mechanism is generally a rectangular frame with a through groove at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com