Straight stroke spring return hydraulic actuator

A technology of spring return and actuator, which is applied in the direction of engine components, mechanical equipment, fluid pressure actuators, etc., can solve the problems of single action principle, low integration, few spring return structures, etc., to achieve convenient use and slow down the decline The effect of speed, ease of installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

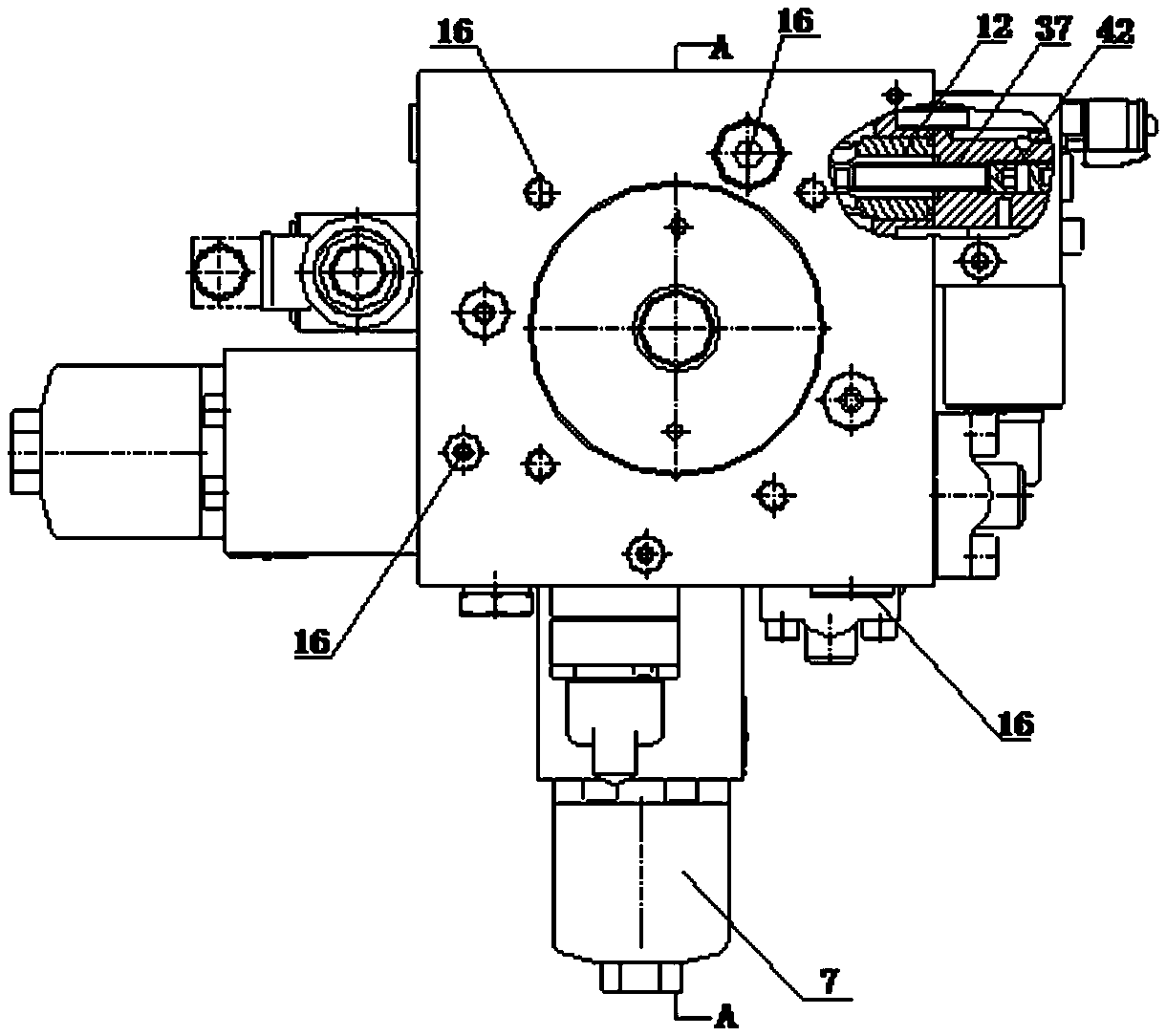

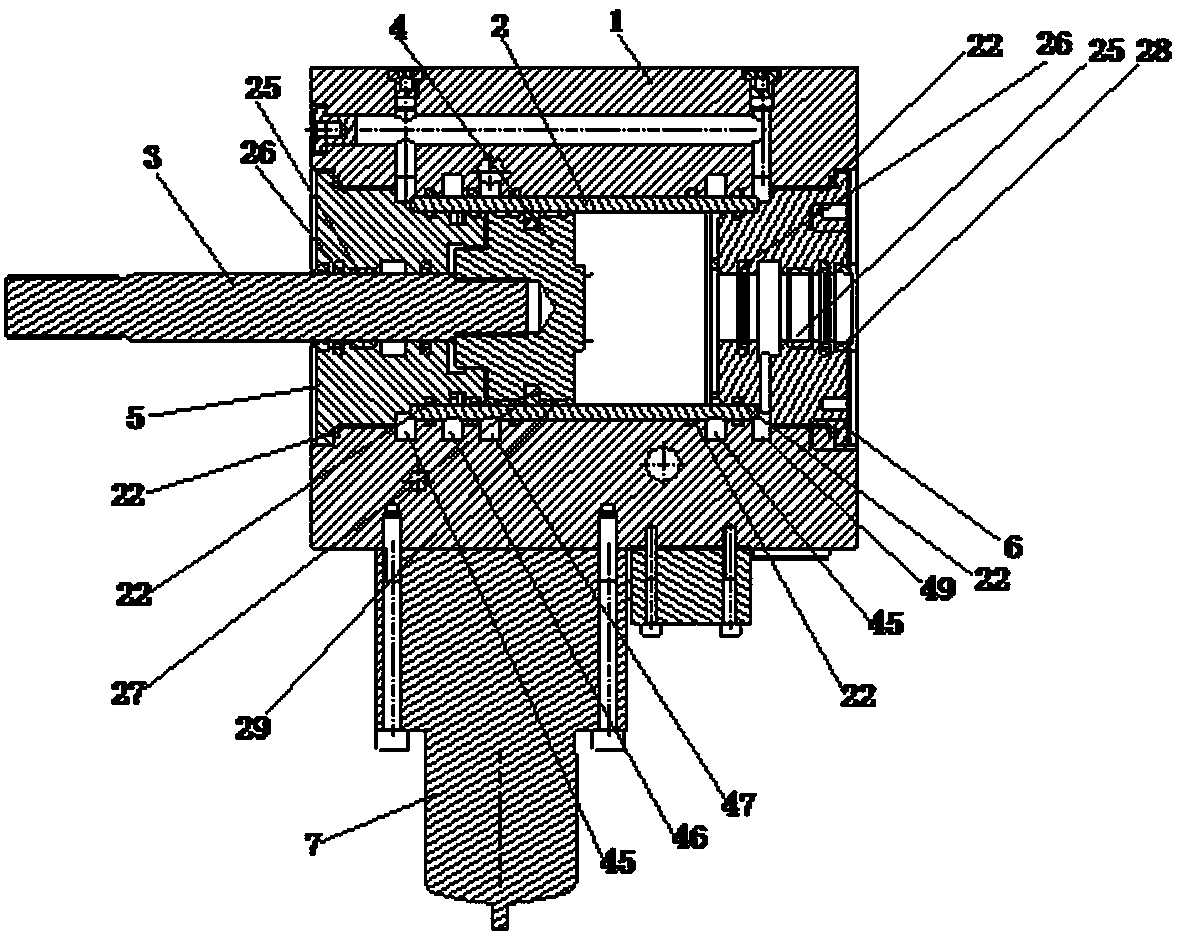

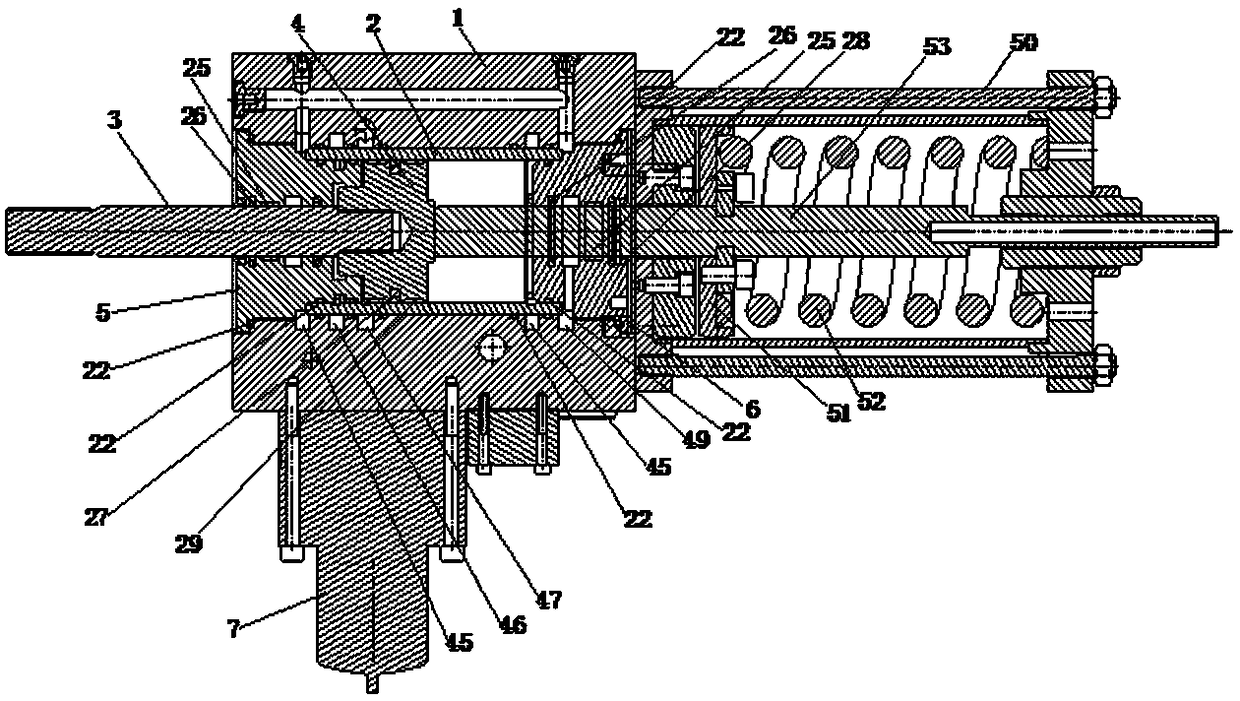

[0029] Such as Figure 1 to Figure 9 As shown, the straight stroke spring return hydraulic actuator of the present invention includes a main oil circuit block 1, in which an oil cylinder 2 is arranged, and a corresponding oil cylinder upper cylinder head 6 and an oil cylinder lower cylinder head are matched. 5. A piston 4 is fitted in the oil cylinder 2, and the piston rod 3 of the piston 4 protrudes from the lower cylinder head 5 of the oil cylinder and the main oil circuit block 1; connected oil circuit, and is matched with corresponding plug; the piston seal 27 and the piston guide ring 29 are arranged at the joint between the piston 4 and the oil cylinder 2; A shaft seal 26 and a shaft guide ring 25; the upper cylinder head 6 of the oil cylinder is provided with a reset mechanism that cooperates with the piston 4 . The linear stroke spring return hydraulic actuator of the present invention, through the cooperation of the main oil circuit block 1, the piston 4, the oil cyl...

Embodiment 2

[0031] As preferred on the basis of the above-mentioned embodiments, the reset mechanism includes a housing 50, a spring seat 51, a spring 52 and a spring shaft 53, and the housing 50 is installed on the right end of the upper cylinder head 6 of the oil cylinder. One end of the spring shaft 53 is slidingly fitted with the outer end of the housing 50, and the other end is in contact with the piston 4 after passing through the upper cylinder head 6 of the oil cylinder and is slidably fitted with the upper cylinder head 6 of the oil cylinder; the spring seat 51 is fixedly mounted on the spring shaft 53 and close to the left end of the housing 50 , the spring 52 is sleeved on the spring shaft 53 and is located between the spring seat 51 and the right end of the housing 50 . A spring shaft 53 and a spring seat 51 are provided, which improves the speed and accuracy of the spring 52 returning.

Embodiment 3

[0033] As preferably, the spring shaft 53 is provided with a shaft seal 26 and a shaft guide ring 25 where the spring shaft 53 cooperates with the upper cylinder head 6 of the oil cylinder, and the right end of the upper cylinder head 6 of the oil cylinder is provided with an anti-corrosion ring that cooperates with the spring shaft 53 The dust ring 28 not only improves the sealing performance, but also facilitates reset and improves the speed and accuracy of reset.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com