Method for identifying flow characteristic curve of governing valve for steam turbine based on DCS (Distributed Control System) data mining

A technology of data mining and flow characteristics, applied in the direction of electrical digital data processing, special data processing applications, mechanical equipment, etc., can solve the problem of dynamic and static response characteristics deterioration, load response speed and amplitude that cannot meet the requirements of the power grid, and affect the unit economy sexual issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

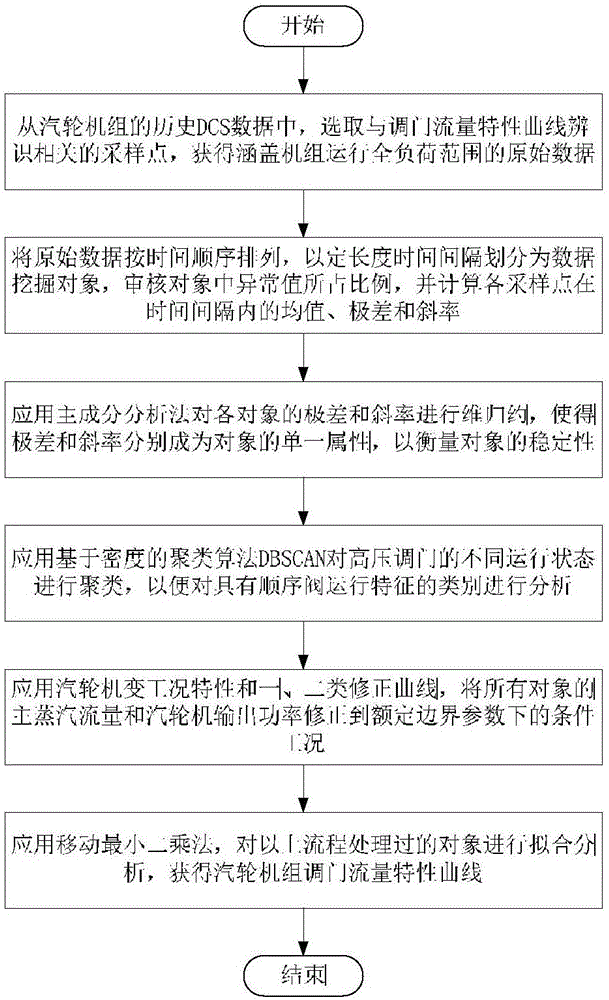

[0043] The method for identifying the flow characteristic curve of the steam turbine valve based on DCS data mining of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0044] 1. From the historical DCS database of the steam turbine unit, select sampling points related to the identification of the flow characteristic curve of the control valve. The sampling points include main steam pressure, main steam temperature, regulating stage pressure, regulating stage temperature, reheat steam pressure, reheat steam Temperature, valve opening, main feed water flow, superheater desuperheating water flow, reheater desuperheating water flow, steam turbine output power and low-pressure cylinder exhaust pressure, set the sampling period to be less than or equal to 30 seconds, and the sampling time can cover the operation of the unit full load range.

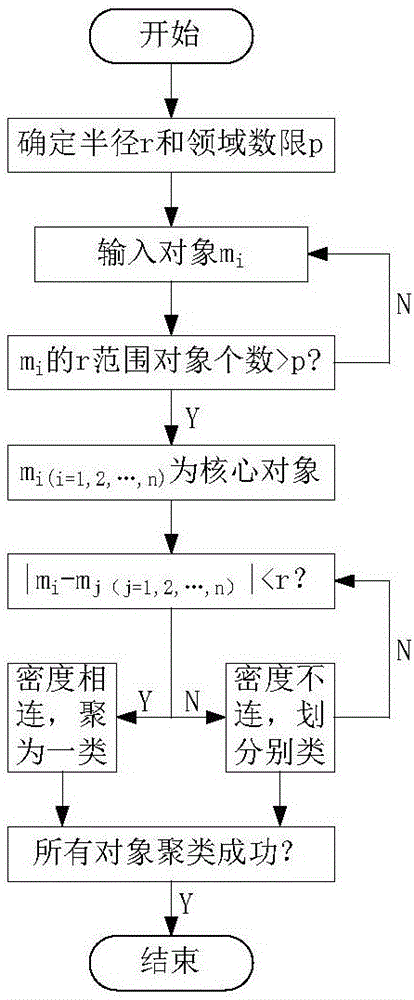

[0045] 2. Arrange the original data in chronological order, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com