A mesh breathable wide and narrow knitted belt and its manufacturing method

A technology of wide and narrow knitting and manufacturing method, applied in the directions of knitting, warp knitting, textiles and paper making, etc., can solve the problems of poor air permeability, single shape, heavy weight, etc., and achieve the effects of alleviating pressure, comfortable wearing and novel appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

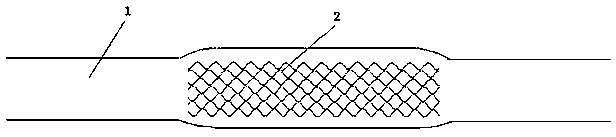

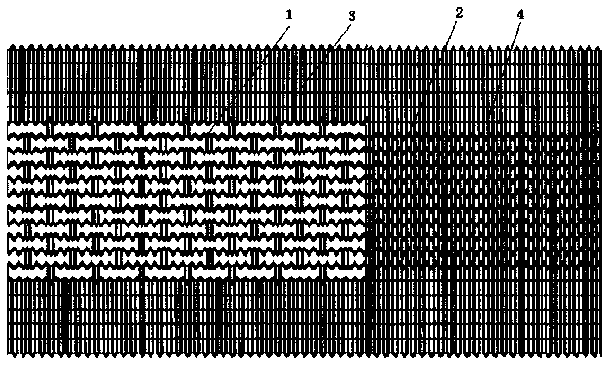

[0019] as attached figure 1 and 2 As shown, the present invention discloses a mesh breathable wide and narrow knitted belt, comprising a main body of the belt, on which the main body of the belt is provided with a narrow solid section 1 and a wide mesh section 2, and the width of the wide mesh section 2 is greater than that of the narrow mesh section. The width of the solid section 1, the narrow solid section and the wide mesh section are integrally crocheted in the same crochet knitting machine that knits electronically driven combs. The narrow solid section and the wide mesh section are set up in a loop end to end, that is, there are multiple narrow solid sections and wide mesh sections on the main body of the webbing, which are formed by alternating circular weaving. The crochet machine is a cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com