A kind of preparation method of environment-friendly copper alloy strip material

A copper alloy strip material, an environment-friendly technology, applied in the field of preparation of environment-friendly copper alloy strip material, can solve the problems of large material and energy consumption, complex production process, environmental pollution, etc., and achieve improved quality, good fluidity, and improved The effect of production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

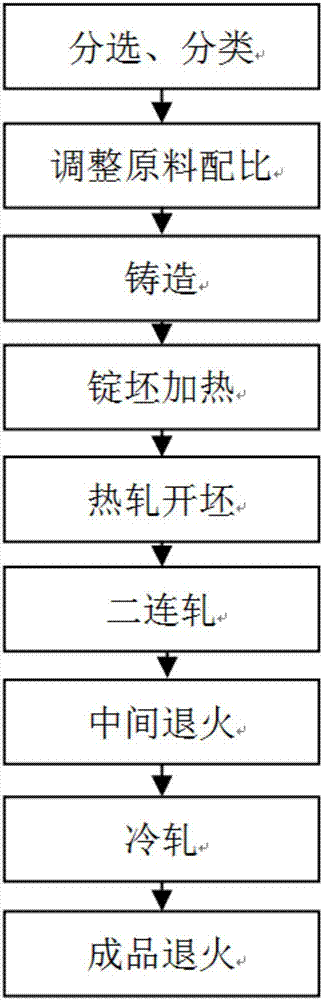

[0026] A method for preparing an environment-friendly copper alloy strip is characterized in that it comprises the following steps:

[0027] (1) Sorting and classification: firstly carry out the test of element content according to the type of waste miscellaneous copper, then sort and classify according to the test results and carry out the mark of element content to the described waste miscellaneous copper after classification;

[0028] (2) Adjust the ratio of raw materials: according to the element content of the actual demand, select the scrap copper that meets the requirements for smelting. Carrying out the test of the content, comparing the test result with the element content of the actual requirement, and adding the corresponding element to the scrap copper by calculation for the element that does not meet the element content of the actual requirement, Get the ratio of raw materials that meet the actual needs;

[0029] (3) Casting: Melting the raw materials obtained in...

Embodiment 2

[0043] The method for preparing an environment-friendly copper alloy strip as described above, the difference of this embodiment is that it includes the following steps:

[0044] (1) Sorting and classification: firstly carry out the test of element content according to the type of waste miscellaneous copper, then sort and classify according to the test results and carry out the mark of element content to the described waste miscellaneous copper after classification;

[0045](2) Adjust the ratio of raw materials: according to the element content of the actual demand, select the scrap copper that meets the requirements for smelting, the smelting temperature is 1080°C, and the smelting time is 1.5h. The content of the element is tested, and the test result is compared with the element content of the actual requirement. For the element that does not meet the element content of the actual requirement, the corresponding element is added to the scrap copper by calculation. , to get t...

Embodiment 3

[0054] The method for preparing an environment-friendly copper alloy strip as described above, the difference of this embodiment is that it includes the following steps:

[0055] (1) Sorting and classification: firstly carry out the test of element content according to the type of waste miscellaneous copper, then sort and classify according to the test results and carry out the mark of element content to the described waste miscellaneous copper after classification;

[0056] (2) Adjust the ratio of raw materials: according to the element content of the actual demand, select the scrap copper that meets the requirements for smelting, the smelting temperature is 1150°C, and the smelting time is 1.5h. The content of the element is tested, and the test result is compared with the element content of the actual requirement. For the element that does not meet the element content of the actual requirement, the corresponding element is added to the scrap copper by calculation. , to get ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com