Coating method for high-speed rail concrete surface strong waterproof thin coating type polyurethane paint

A technology for concrete surface and polyurethane coating, applied in the direction of polyurea/polyurethane coating, anti-corrosion coating, coagulation pavement for on-site paving, etc., can solve the problems of high use cost, difficult construction, failure, etc., and achieve good tensile performance and temperature change resistance, overcoming the effect of short construction operation time and improved waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

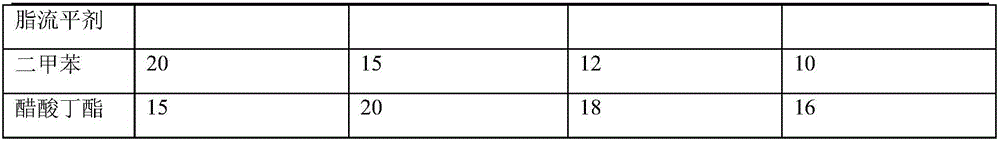

[0023] The technical solutions of the present invention will be further described below in conjunction with specific embodiments. The raw materials used in the embodiments of the present invention are all purchased from existing market suppliers, and the pure purity raw materials are analyzed. The following forms illustrate the components and contents of each paint layer. The unit is g, and the order of addition in the summary of the invention is adopted. Prepared with stirring.

[0024] Preparation of the first resin component of the primer

[0025]

Example 1

Example 2

Example 3

Example 4

hydroxyl terminated polybutadiene

50

55

0

0

Polytetrahydrofuran ether glycol

0

0

55

50

Anatase Titanium Dioxide

25

15

20

18

Barium sulfate

5

4

5

3

mesochrome

8

4

6

6

Bentonite

8

5

7

6

1,4-Butanediol

15

0

0

0

Ethylene glycol

0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com