Method and device for condensing, cooling and separating material from top of stabilizer tower in benzene hydrogenation process

A technology of condensing cooling and condensing cooler, which is applied in the direction of distillation purification/separation, organic chemistry, etc. It can solve the problems of unstable tower pressure, unsmooth liquid discharge, and stagnant liquid, so as to improve the effect of gas-liquid separation, The effect of small footprint and stable operation indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

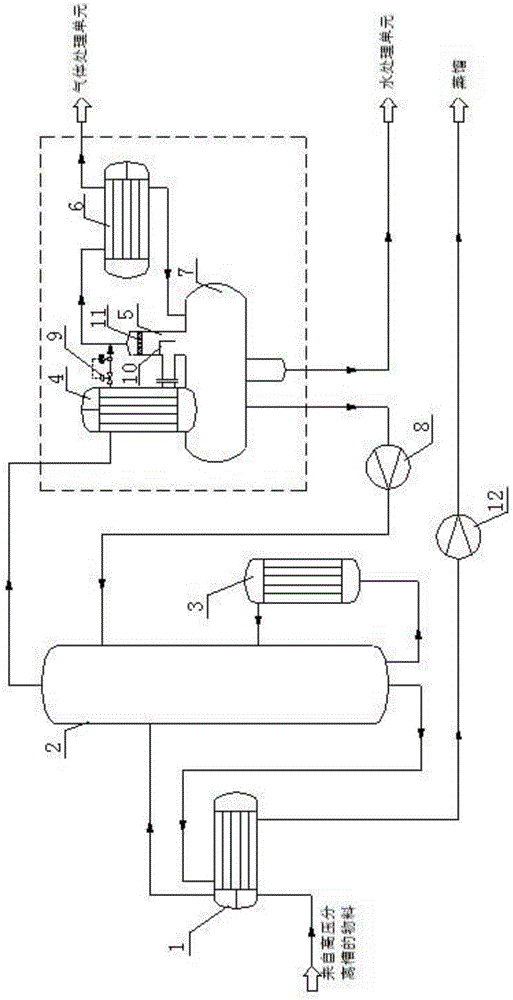

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0023] Such as figure 1 As shown, in the benzene hydrogenation process of the present invention, the method for condensing, cooling and separating the overhead material of the stabilization tower comprises the following steps:

[0024] 1) During the production process, the stable tower top material including impurity gas and product vapor is condensed and cooled in the tower top condensing cooler 4; under the control of the flow regulating valve 9, most of the gas directly enters the exhaust condensing cooler 6, a small Part of the liquid-entrained gas enters the gas-liquid separator 5; the liquid in the top condensation cooler 4 passes through the gas-liquid separator 5 and then enters the reflux tank 7;

[0025] 2) The gas phase separated by the gas-liquid separator 5 is discharged after the mist catcher 11 at the top of the gas-liquid separato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com