Rainwater remover for automobile windshield

A windshield and clearer technology, applied in the automotive field, can solve the problems of troublesome replacement and maintenance, long wiper length, wiper scraping, etc., and achieves the effects of reduced maintenance and replacement costs, longer service life, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

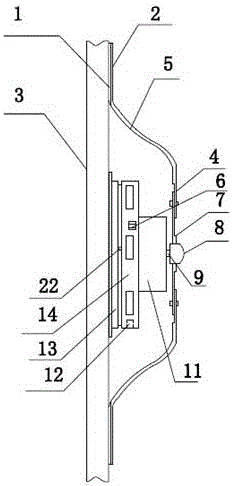

[0035] figure 1 It is a schematic diagram of the overall assembly structure of the first embodiment, figure 1 Among them, a fixing device, a power drive device and a cleaning device are included. The fixing device is used to fit the windshield 3 of the car. Since the windshield 3 has a relatively smooth surface, the fixing device selects a sealing suction cup 13, and the sealing suction cup 13 has an adsorption chamber 19 inside, and when in contact with the windshield 3, the adsorption is mainly completed through the adsorption chamber 19;

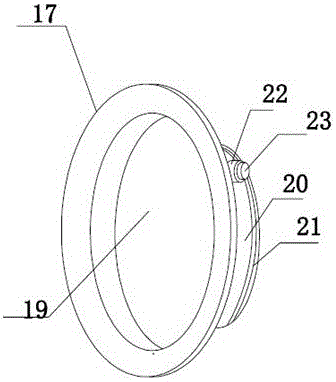

[0036] Such as figure 2 As shown, since the sealing suction cup 13 is made of silica gel material, the texture is relatively soft, so in order to effectively fix the power drive device installed on one side, a protective casing 20 is specially arranged on the back of the sealing suction cup, and the protective casing 20 is hard. quality metal material, the inside of the sealed suction cup 13 is embedded in the protective shell 20;

[...

Embodiment 2

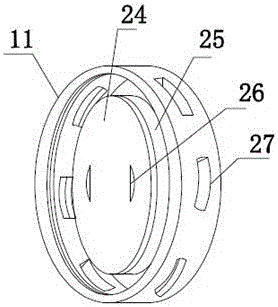

[0059] Such as Image 6 as shown, Image 6 It is the second deformation method of the fixing device. In order to ensure the fixing force between the whole device and the windshield surface, more than one suction cavity 18 is specially set on the edge part of the sealing suction cup, and the suction cavity 18 adopts an inner concave structure;

[0060] In order to be able to absorb, in this embodiment, the thickness of the edge part can be increased. After the concave suction cavity contacts the glass surface, it can absorb the glass surface, and the suction cavity is preferably around the edge part. set so that the edge portion can have a uniform fixing capacity in all directions;

[0061] The function and structure of these suction cavities are the same as those of ordinary small suction cups, and it is not easy to make the suction cavities too large, otherwise it will affect the sealing performance of the sealing suction cup;

[0062] Figure 7 as shown, Figure 7 It is...

Embodiment 3

[0066] Figure 8 It is a schematic structural diagram of a sealed suction cup according to Embodiment 3 of the present invention;

[0067] Figure 8 Among them, the sealing suction cup is another deformation structure, the main purpose is to set up an independent auxiliary suction structure, and set more than one lug 33 around the outside of the edge part, and the suction cavity 32 is set on the lug 33 , the purpose of which is to reduce the influence of the suction cavity 32 on the adsorption of the sealing suction cup, so that it can have an independent auxiliary fixing structure;

[0068] The contact area between the entire sealing suction cup and the windshield surface is also greatly increased, so its adsorption capacity will also be greatly increased, such as Figure 8 As shown, this structure makes the installation more uniform, and its sealing effect is better than that in the first embodiment and the second embodiment.

[0069] In embodiment 3, other structures are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com