Hydraulic coordinated biomass sawing equipment

A biomass and sawing technology, applied in sawing equipment, circular saws, grain processing and other directions, can solve the problems of high drying requirements of biomass raw materials, increased production costs, low crushing efficiency, etc., to reduce drying costs. , the effect of fast sawing speed and high crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

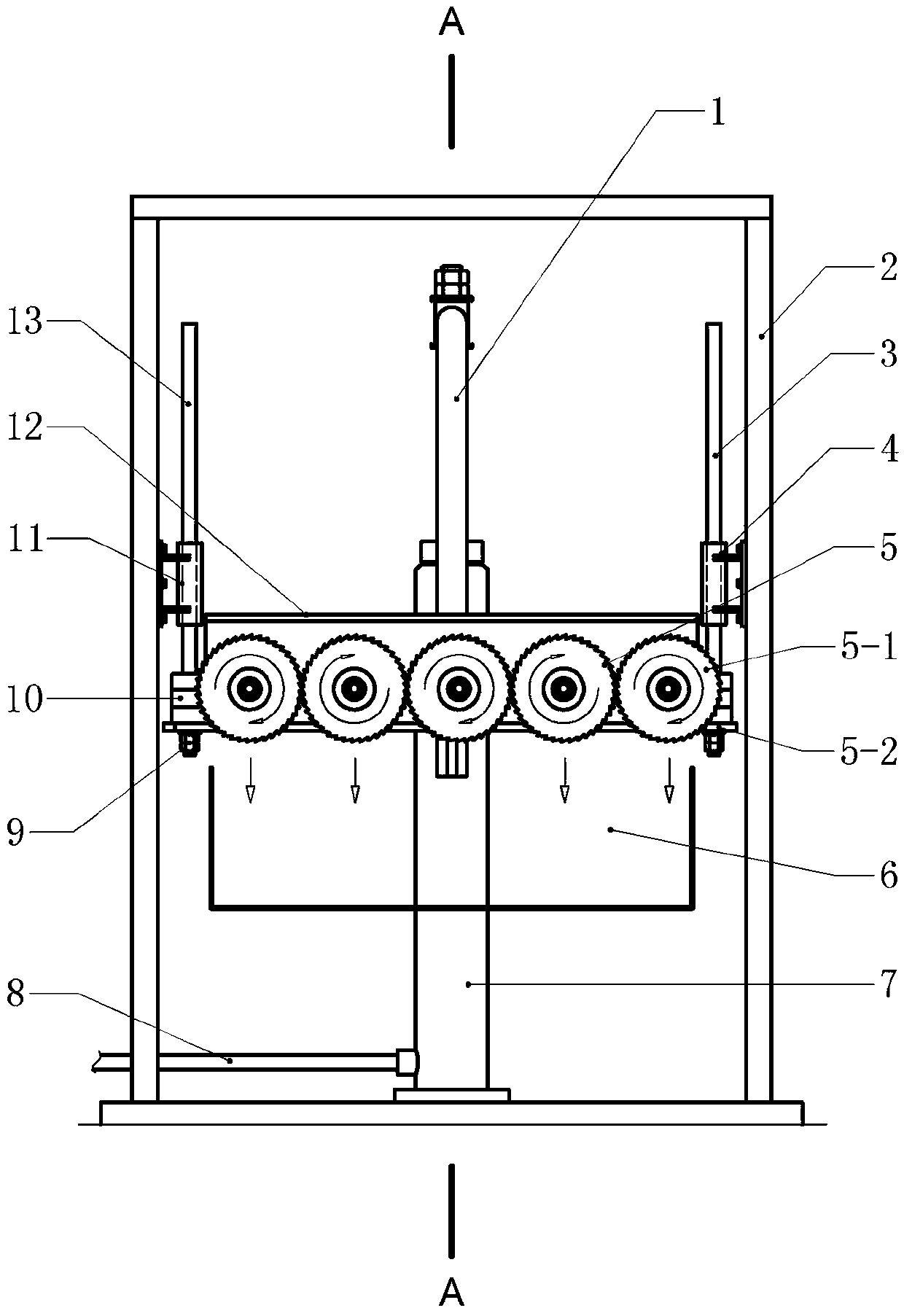

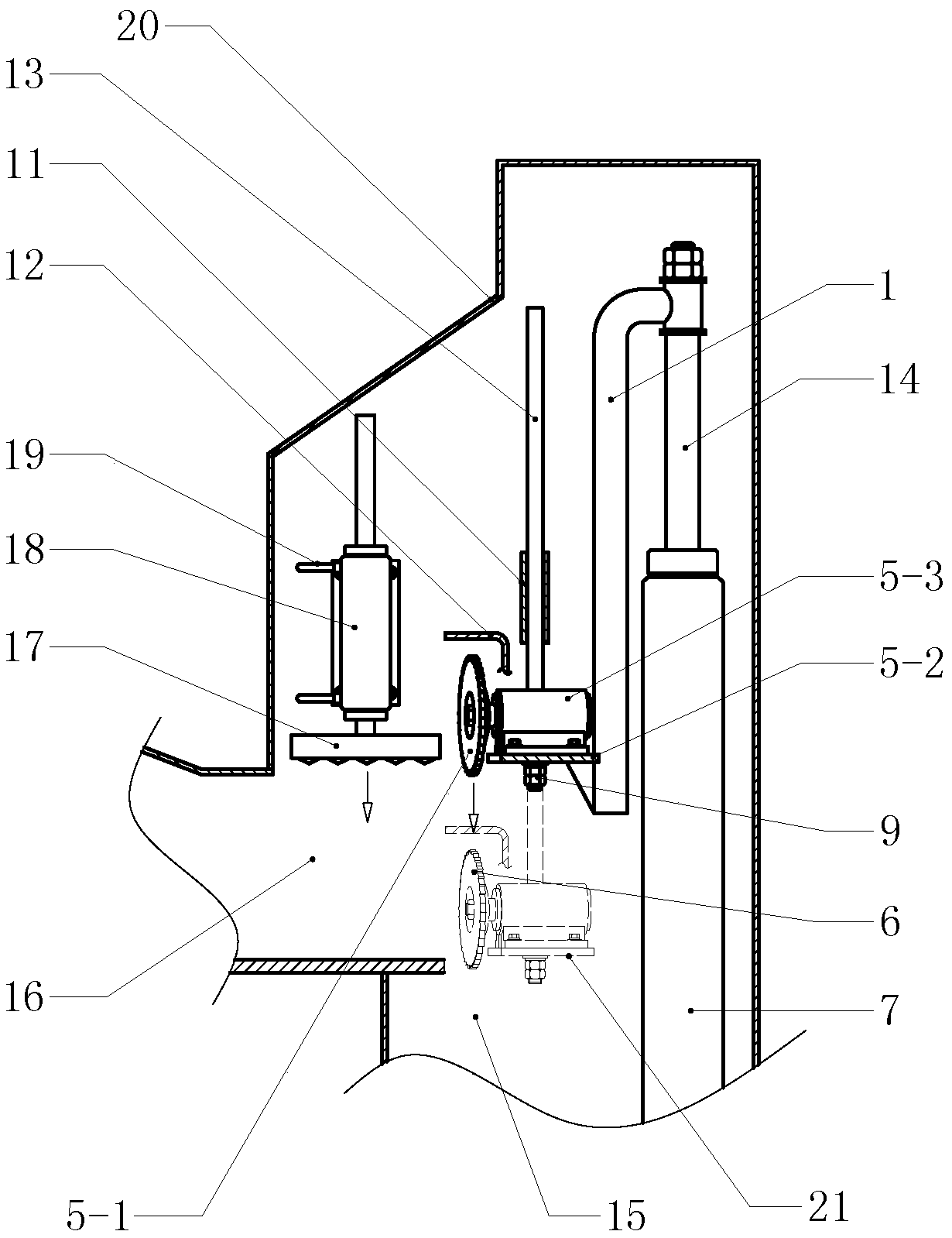

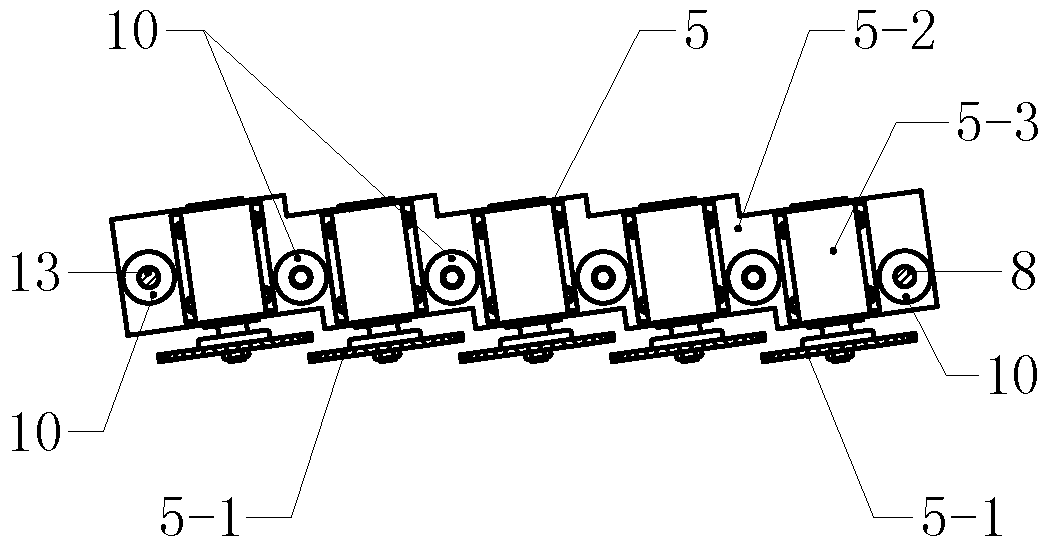

[0015] Example Figure 1-3 In the shown embodiment, the hydraulically coordinated biomass sawing equipment mainly consists of a hydraulic cylinder 7, a frame 2, a saw row assembly 5, a lifting rod 1, a left guide rail 11, a left guide rod 13, a right guide rail 4, and a right guide rod 3 and the enclosure 20, the hydraulic cylinder 7 and the frame 2 are arranged in the enclosure 20, the upper end of the hydraulic cylinder 7 has a hydraulic column 14 protruding; the saw row assembly 5 is composed of a lifting chassis 5-2, a small high-speed motor Composed of multiple circular saw blades, a counterweight 10 is arranged on the saw row assembly 5; multiple small high-speed motors are arranged on the lifting chassis 5-2, and circular saw blades are installed on the rotating shafts of each small high-speed motor. The circular saw blades are arranged horizontally in a straight line, and the sawing direction of the circular saw blades is vertically downward. There is a horizontal ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com