Insulating nozzle of welding gun

A technology of insulating nozzles and nozzles, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effects of reduced loss, stable structure, and good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

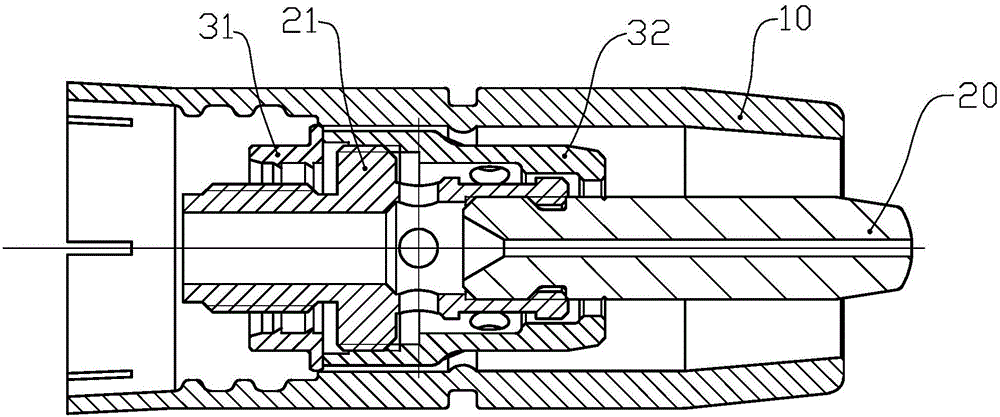

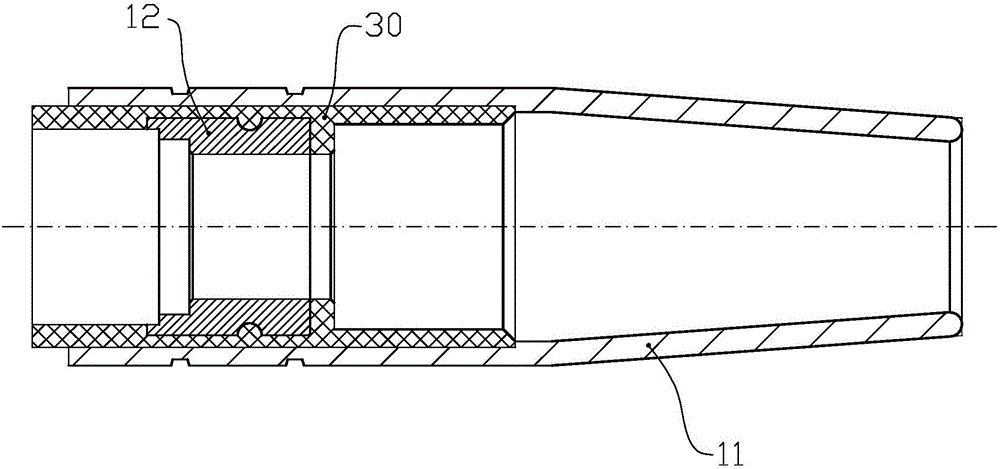

[0014] In order to facilitate the understanding of the technical content of the present invention, the technical solution thereof will be further described below in conjunction with the accompanying drawings and the operation process.

[0015] Such as figure 2 The shown insulating nozzle of a welding torch includes a nozzle outer tube 11, a nozzle inner tube 12 and an insulator 30. The insulator 30 is arranged between the nozzle inner tube 12 and the nozzle outer tube 11 in the form of injection molding. After injection molding, it should ensure that The axes of the nozzle outer tube 11 , the nozzle inner tube 12 and the insulator 30 are coincident. The right end surface of the insulator 30 extends to the inner end of the nozzle outer tube 11 shrinkage cavity, and the left end surface of the insulator 30 extends axially outward for a certain length relative to the left end surface of the nozzle inner tube 11 .

[0016] A groove is arranged on the outer wall of the nozzle inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com