Hedge Type Secondary Grinding Machine

A secondary grinding and hedging technology, which is applied in the field of grinding machines, can solve problems such as weak pertinence, and achieve the effects of improving production efficiency, increasing contact area, and fine secondary grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below according to the drawings and embodiments.

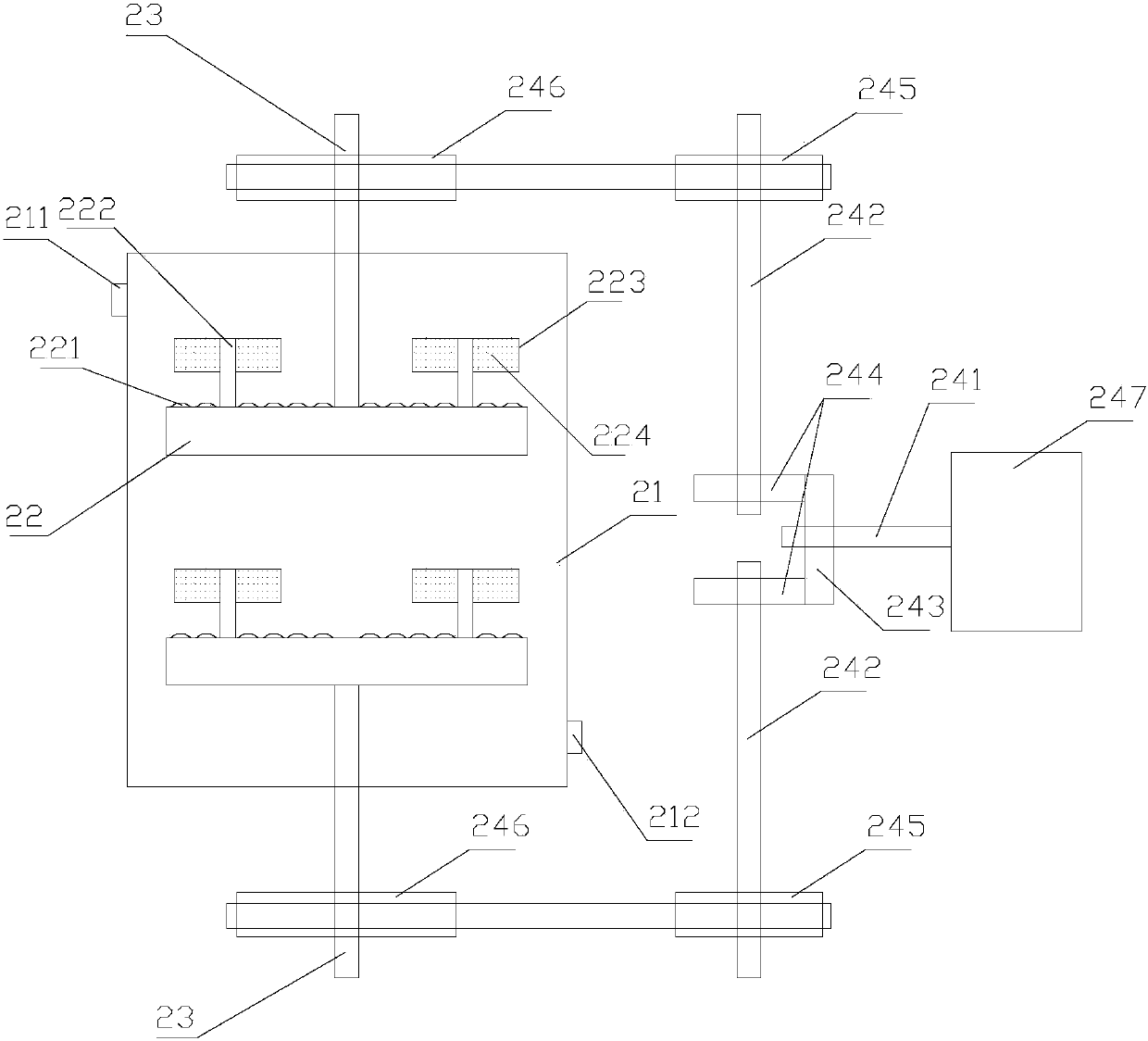

[0012] figure 1 It is the structural representation of the opposite type secondary grinder of the present invention, with reference to figure 1 , the present invention, the hedge-type secondary grinder includes a secondary grinder shell 21 and a secondary grinder, the upper portion of the secondary grinder shell 21 is provided with a secondary grinder inlet 211, and the bottom is provided with a secondary grinder outlet 212, the above-mentioned The secondary grinding device comprises two grinding discs 22, two grinding disc rotating shafts 23, and a secondary grinding driving device. The above-mentioned grinding discs 22 are arranged horizontally in the above-mentioned secondary grinding machine housing 21 and are all sleeved on the above-mentioned grinding disc rotating shafts 23. The above-mentioned grinding discs 22 are in a vertical relationship and opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com