Mobile glass lining reaction vessel with vibrating function and regulating function

A glass-lined and reaction tank technology, applied in the field of movable glass-lined reaction tanks, can solve the problems of not being able to measure the temperature very accurately, changing the efficiency and speed of stirring, and being unable to measure the temperature, so as to improve the stirring efficiency and reduce the labor force , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

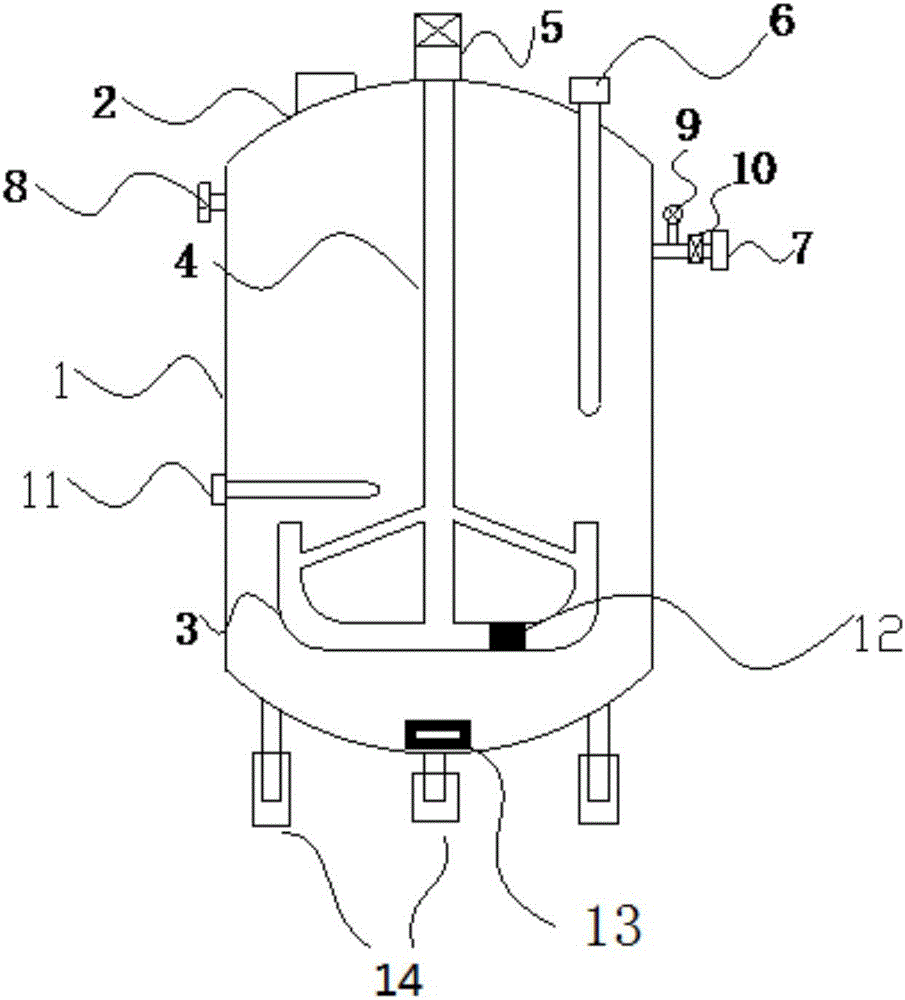

[0012] Such as figure 1 As shown, a movable glass-lined reaction tank with vibration function and adjustment function, it includes a tank body 1, a tank cover 2, a steam inlet 8, an agitator 4 with a stirring blade 3, and an agitator 4 connected to the agitator 4 Motor 5, electric control box, speed sensor 12, action wheel 14, electric control box and motor 5 are electrically connected, speed sensor 12 is installed on the stirring paddle 3 at the bottom of agitator 4, passes through the tank cover 2 and is placed vertically in the tank body The thermometer I6 in 1, the tank body 1 is also provided with a steam outlet 7, the steam outlet 7 is provided with a pressure gauge 9 and an automatic pressure relief valve 10, and the lower part of the tank body 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com