Floor mopping machine and spraying structure of same

A mopping machine and nozzle technology, applied in the field of mopping machines, can solve the problems of compression volume, inconvenient use, large bottom shell volume, etc., and achieve the effects of weight reduction, ease of use, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

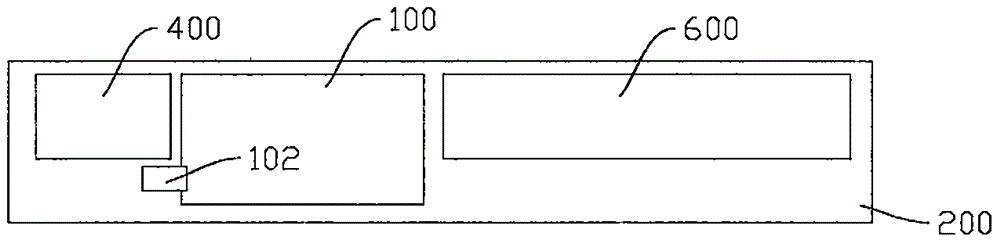

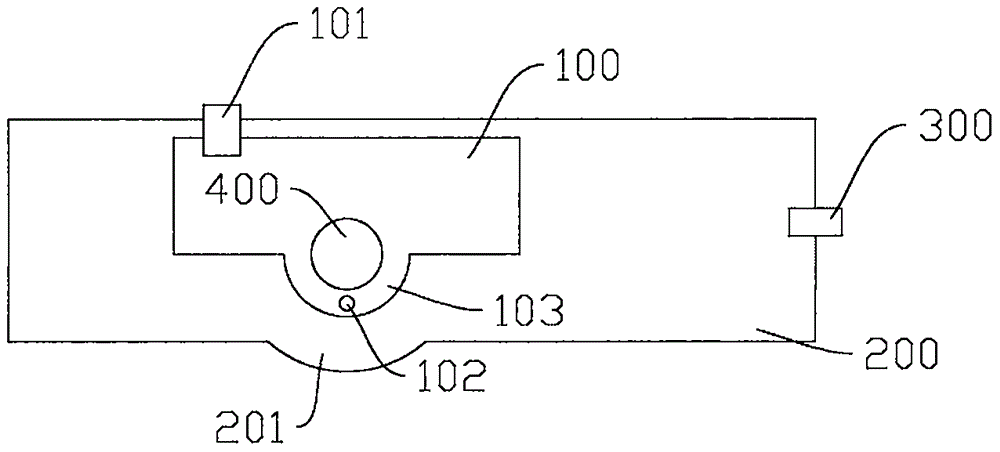

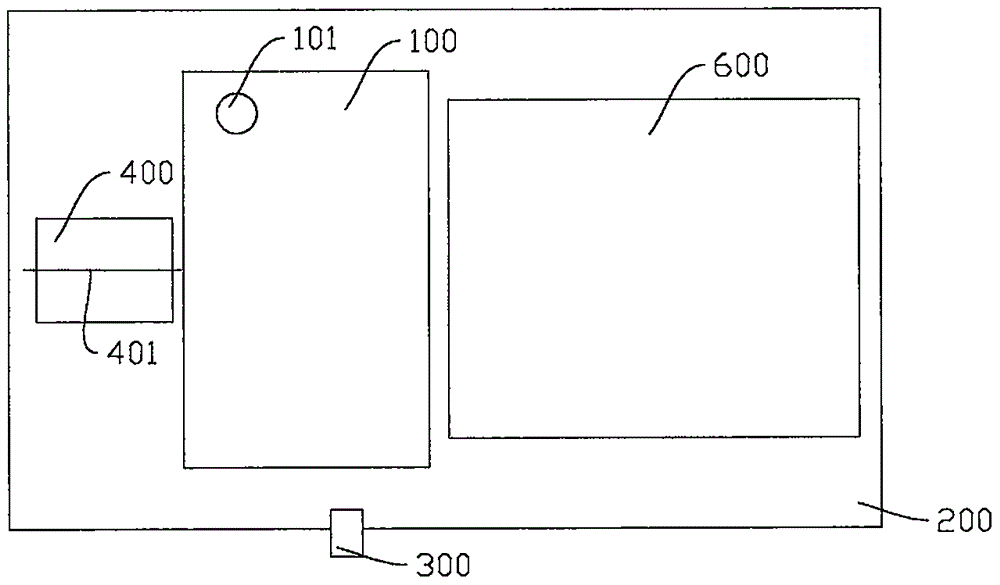

[0030] Such as Figure 1-3 As shown, the legend shown in the drawings is a brief explanatory diagram, and for the sake of clarity, the proportional relationship of the components between the various drawings is not one-to-one correspondence.

[0031] A sprinkler structure for a mopping machine, comprising a tank 100 and a pump device 400 for sucking liquid in the tank 100 and spraying it out through a nozzle 300 provided on a bottom shell 200 of the mopping machine. The box body 100 is used to hold the spraying liquid of the mopping machine. Generally, the liquid that can be used includes water, and in some cases, other liquid sprays can also be used. The pump device 400 can use various types of pumps, including gear pumps or diaphragm pumps, and can also use other similar pumps. The spray structure described in this embodiment makes it possible to use other types of pumps. The pump device 400 sprays the liquid for spraying from the nozzle 300 by suction. The above-mentioned...

Embodiment 2

[0049] A floor mopping machine using the spray structure described in the above-mentioned embodiment 1, including the spray structure described in the above-mentioned embodiment 1, wherein the pump device 400 of the spray structure is controlled by a control device connected in a wireless manner . The control unit can be placed in the handle of the mopping machine, or it can be separated from the mopping machine as an independent part.

[0050] Further, the pump device 400 includes a gear pump or a diaphragm pump, and other similar pumps may also be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com