Motor noise reduction structure

A technology of noise reduction and motor cover, applied in the direction of exhaust diffuser, cleaning equipment, vacuum cleaner, etc., can solve the problems of unsatisfactory sound absorption effect and limited noise reduction space, and achieve the effect of preventing resonance, eliminating noise and eliminating wind noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0035] like

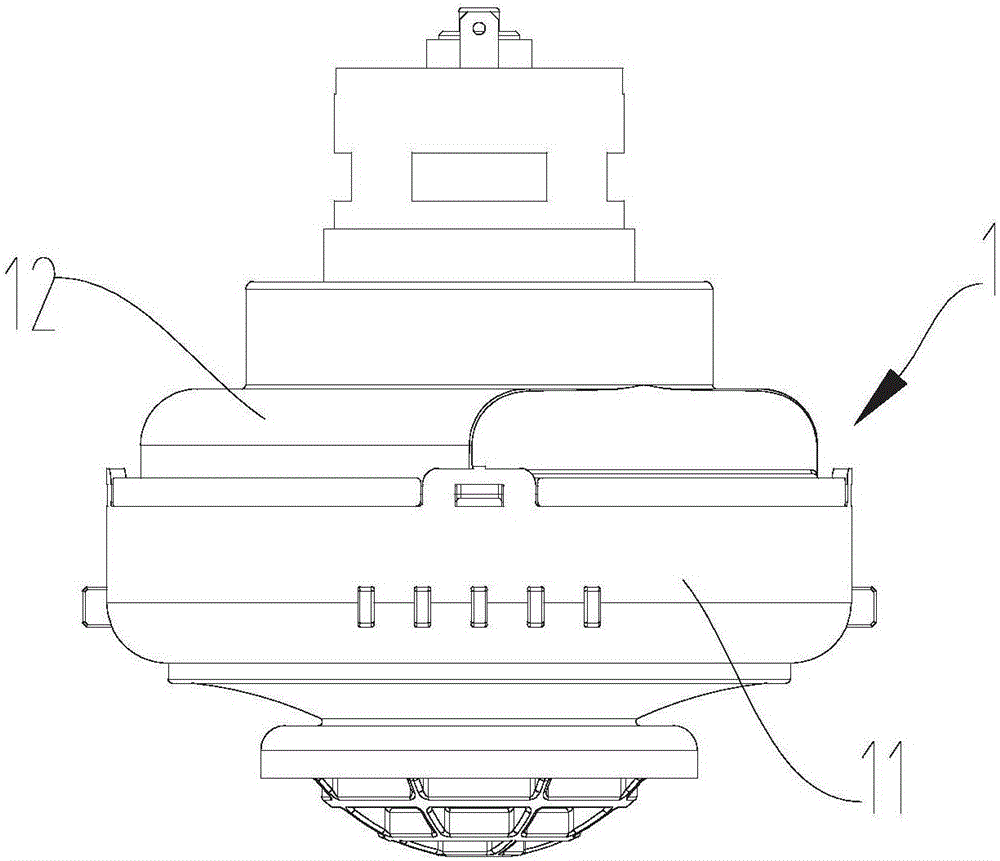

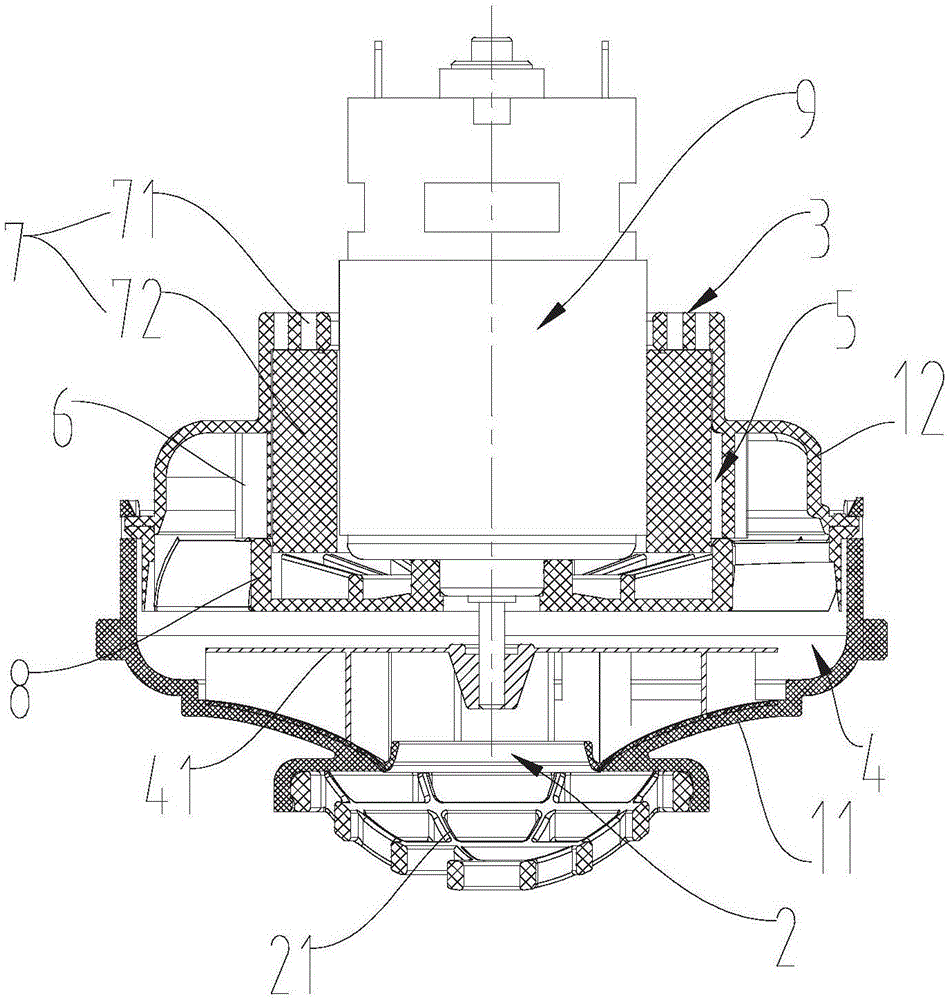

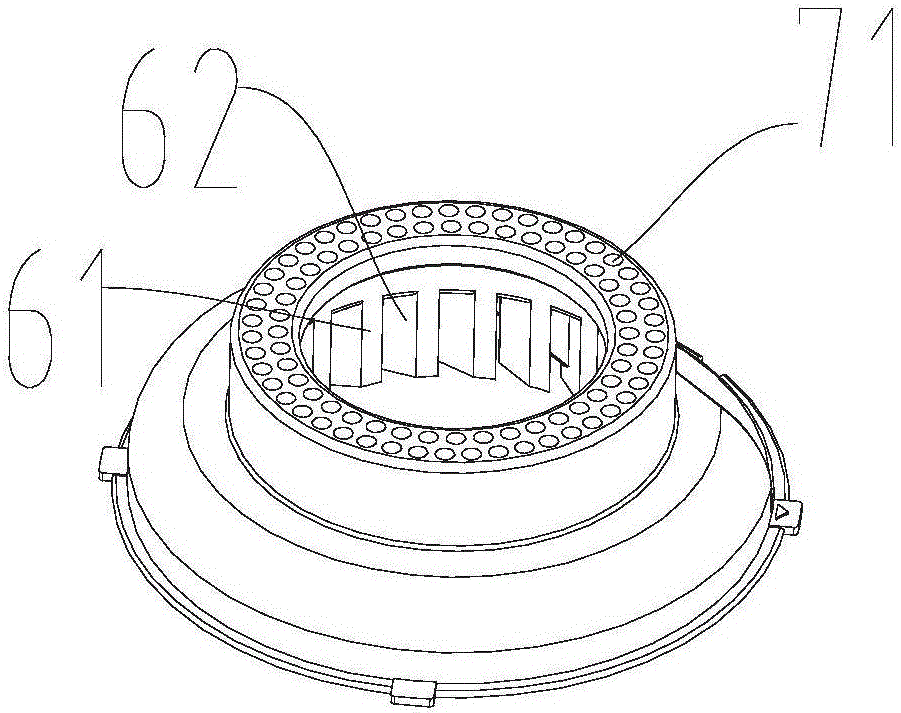

[0036] figure 1 , figure 2 As shown, a motor noise reduction structure includes a motor cover 1 for accommodating a motor 9, and the motor cover 1 includes a moving impeller chamber 4 and a muffler chamber 5 in sequence from the air inlet 2 to the air outlet 3, and the moving impeller chamber 4 is provided with a moving impeller assembly 41, and the sound-absorbing cavity 5 is provided with a first sound-absorbing portion 6 and a second sound-absorbing portion 7, and the first sound-absorbing portion 6 includes an oblique grid, and is arranged on the first sound-absorbing portion The second muffler portion 7 downstream of 6 includes dense small holes 71 arranged at the air outlet 3 and a muffler material 72 arranged inside the air outlet 3 . In this embodiment, the motor cover 1 includes a wind cover 11 and a muffler cover 12 sealingly engaged with the wind cover 11, the moving impeller cavity 4 is arranged in the wind cover 11, the sound-absorbing chamber 5 i...

no. 2 example

[0045] like Figure 8 As shown, the motor noise reduction structure of this embodiment is basically the same as that of the first embodiment, the difference is that only the first noise reduction part 6 is provided in the noise reduction cover 12, that is, only oblique grids are provided.

no. 3 example

[0047] like Figure 9 As shown, the motor noise reduction structure of this embodiment is basically the same as that of the first embodiment, the difference is that only the second noise reduction part 7 is provided in the noise reduction cover 12, that is, only the dense small holes arranged at the air outlet 3 are provided. 71 and the sound-absorbing material 72 arranged inside the air outlet 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com