A crawler type rotary tiller

A rotary tiller and crawler-type technology, which is applied in the field of crawler-type rotary tillers, can solve the problems of difficulty in walking, poor rotary tillage effect, and inconvenient machine position transfer, and achieve flexible machine position transfer, convenient adjustment, and rotary tillage operations high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

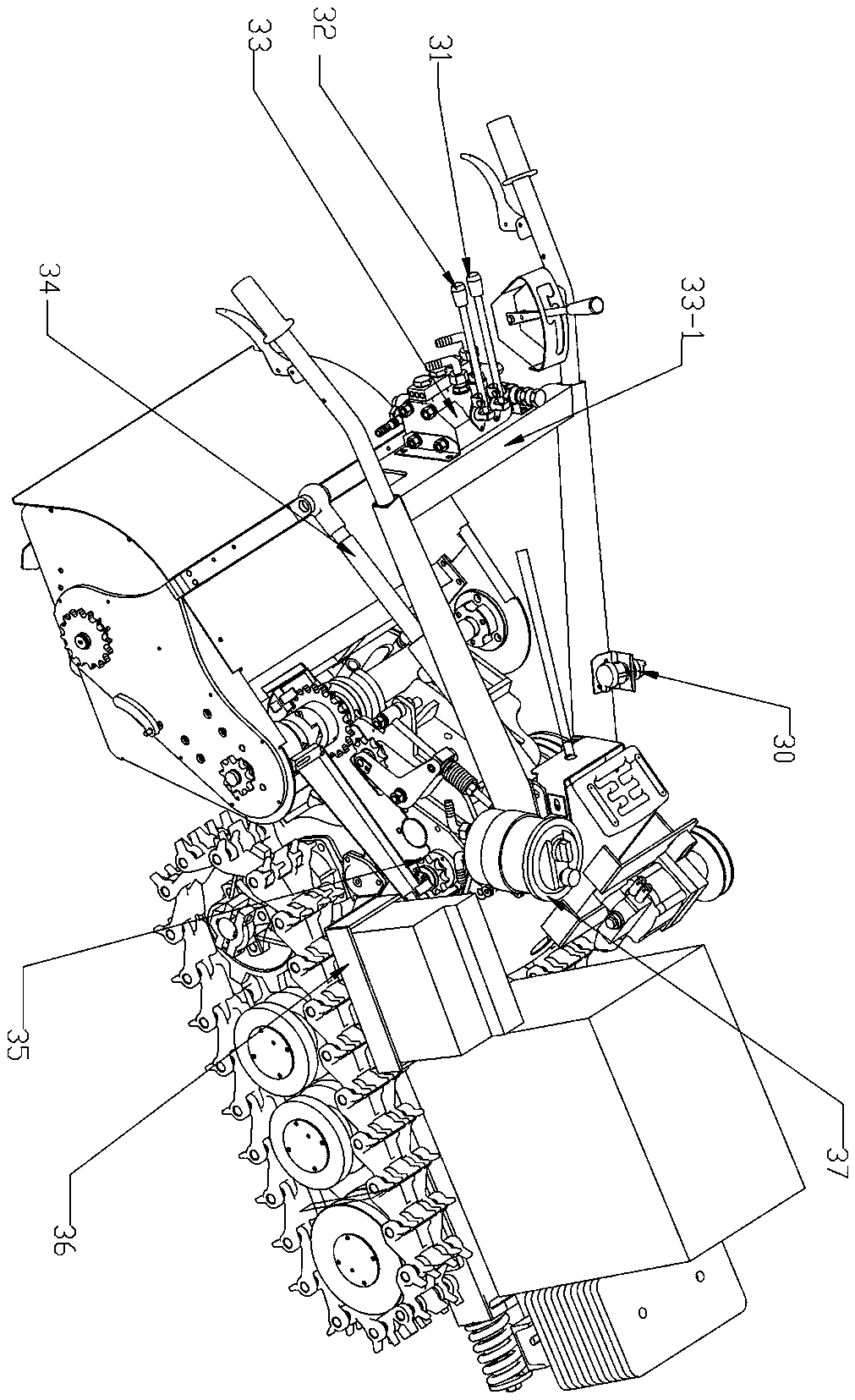

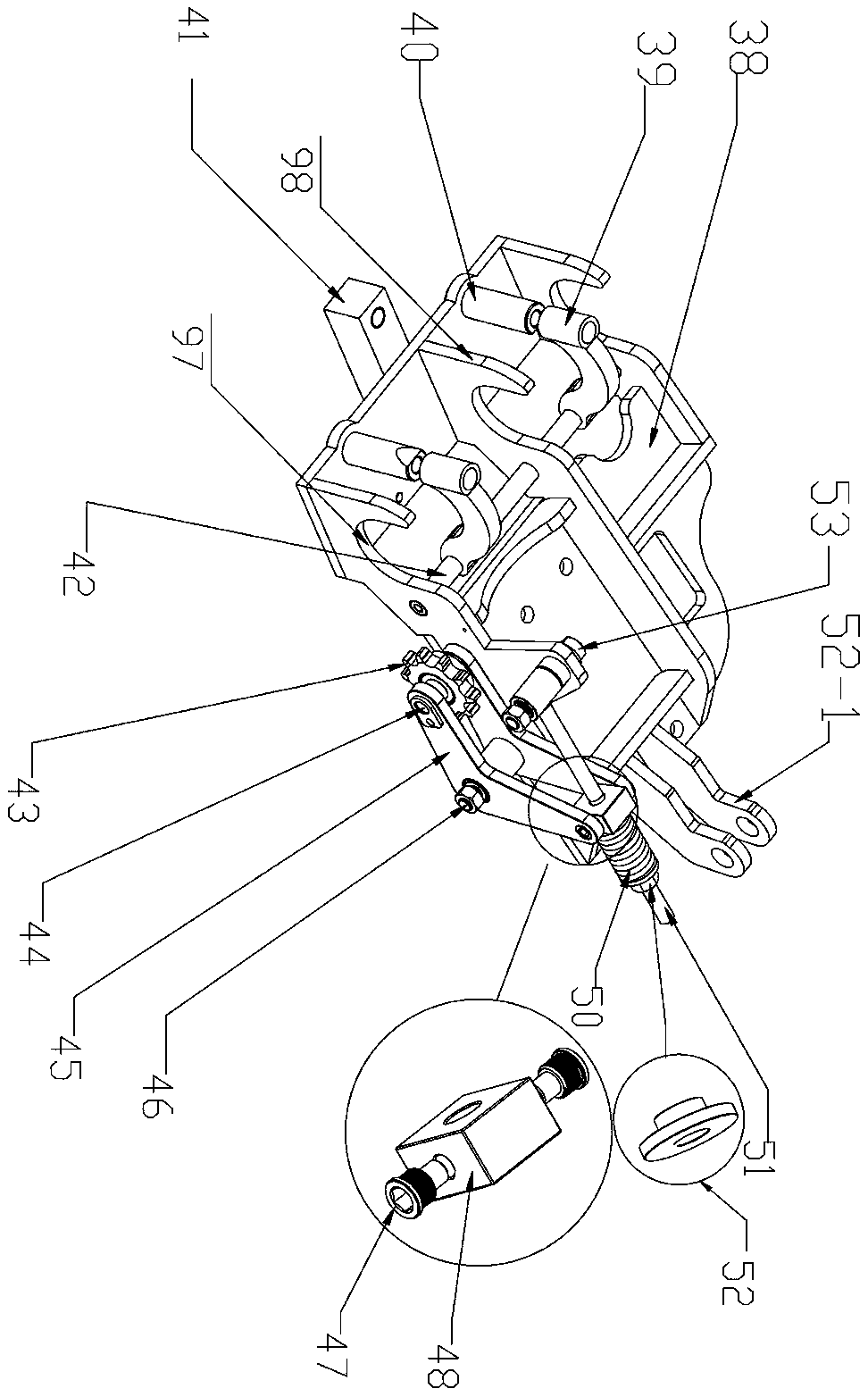

[0028] Embodiment 1: a kind of crawler type rotary cultivator, as Figure 1-8 As shown, including chassis device, power system, control system and rotary tillage device;

[0029]The chassis device is located at the bottom of the rotary tiller, and the frame 1 is set on the bottom of the crawler rotary tiller, which is the carrier of other components and mechanisms; the wheel axle 85 fixes the lower end of the front part of the frame 1, and the upper and lower cylindrical surfaces at both ends are respectively A platform 101 is provided so as to be installed in the long groove 102 of the frame 1 to prevent it from rotating; the tension spring 3 and the spring washer 2-1 are set on the tension column 2 and the spring washer is at the front end of the tension spring 3 , the other end of the tension spring is blocked at the front end of the frame 1, and the tension column 2 is threaded into the thread hole on the wheel axle 185. After the installation is completed, it is ensured t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com