Method for Equipment Monitoring Using Signal and Video Synchronization

A video synchronization and equipment monitoring technology, which is applied in the direction of load hanging components, transportation and packaging, safety devices, etc., can solve the problem that the cause of the accident is difficult to determine, the dispatcher cannot monitor the whole process, and the operation of each part of the vehicle is delayed. Time and other issues, to achieve the effect of intuitively reflecting the situation on the spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, technical features, invention objectives and technical effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

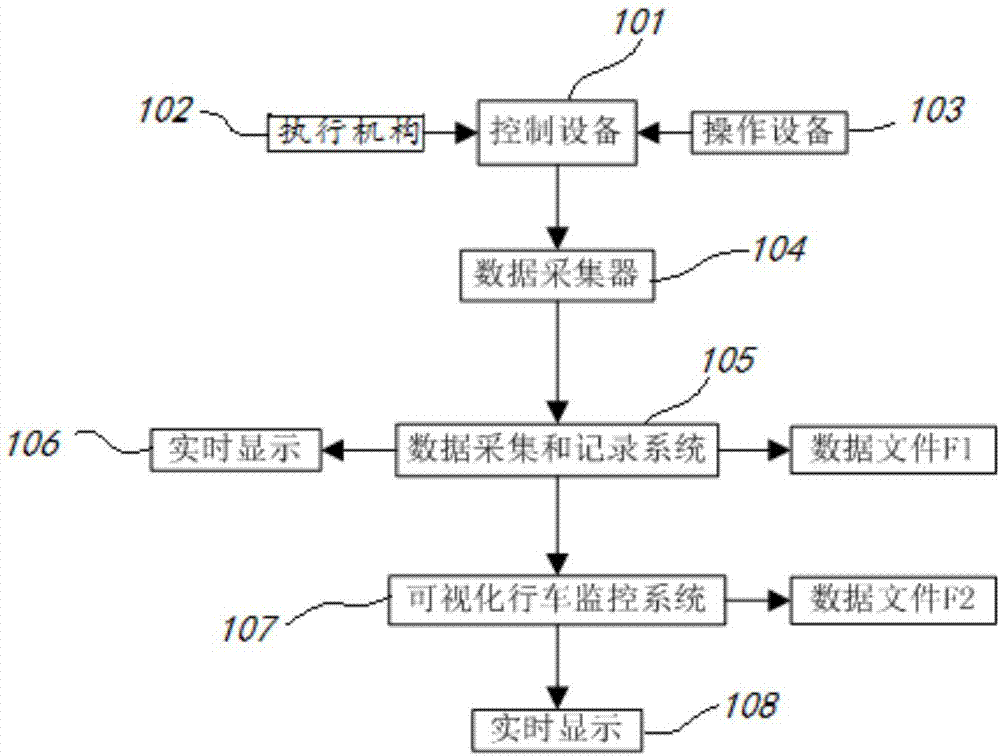

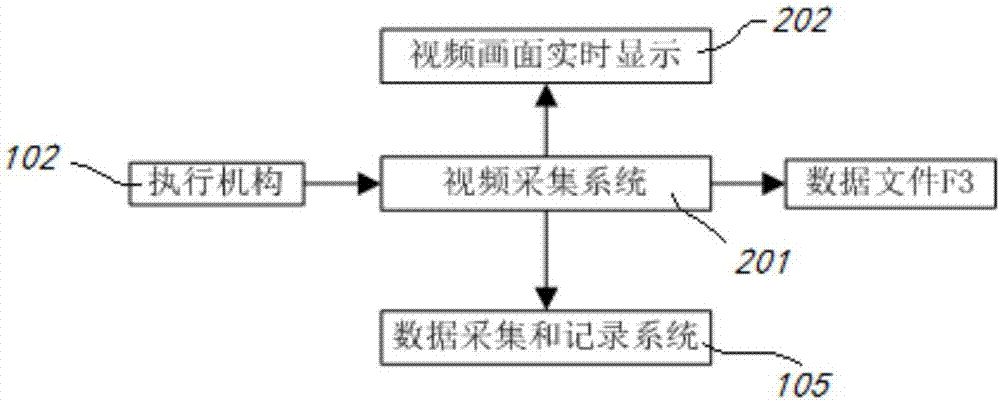

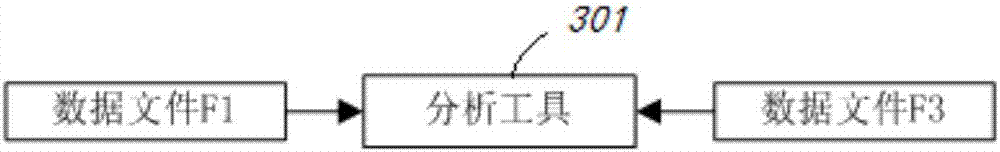

[0033] Such as Figure 1 to Figure 4 , which is a method for equipment monitoring using signal and video synchronization in the present invention, the method includes the following steps:

[0034] Step S1: Record the collection and transmission of the signals of the on-site actuators

[0035] In this step, first, the control device 101 collects signals from the actuator 102 and the operation device 103 , and in this embodiment, the signal from the actuator 102 is transmitted to the control device 101 through the sensor.

[0036] The collected signal is transmitted to the data collector 104 through the control device 101 ; then, the data collector 104 transmits the signal to the data collection and recording system 105 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com