Tin diselenide/polyethyleneimine composite material and preparation method and application thereof

A polyethyleneimine, tin diselenide technology, applied in secondary batteries, electrochemical generators, electrical components, etc., can solve the problem of reducing the cycle stability of electrode materials, reducing the cycle life of sodium ion batteries, and limiting diselenide. tin industrial production and other issues, to achieve broad industrial application prospects, excellent rate performance and cycle stability performance, and the effect of improving rate performance and cycle stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

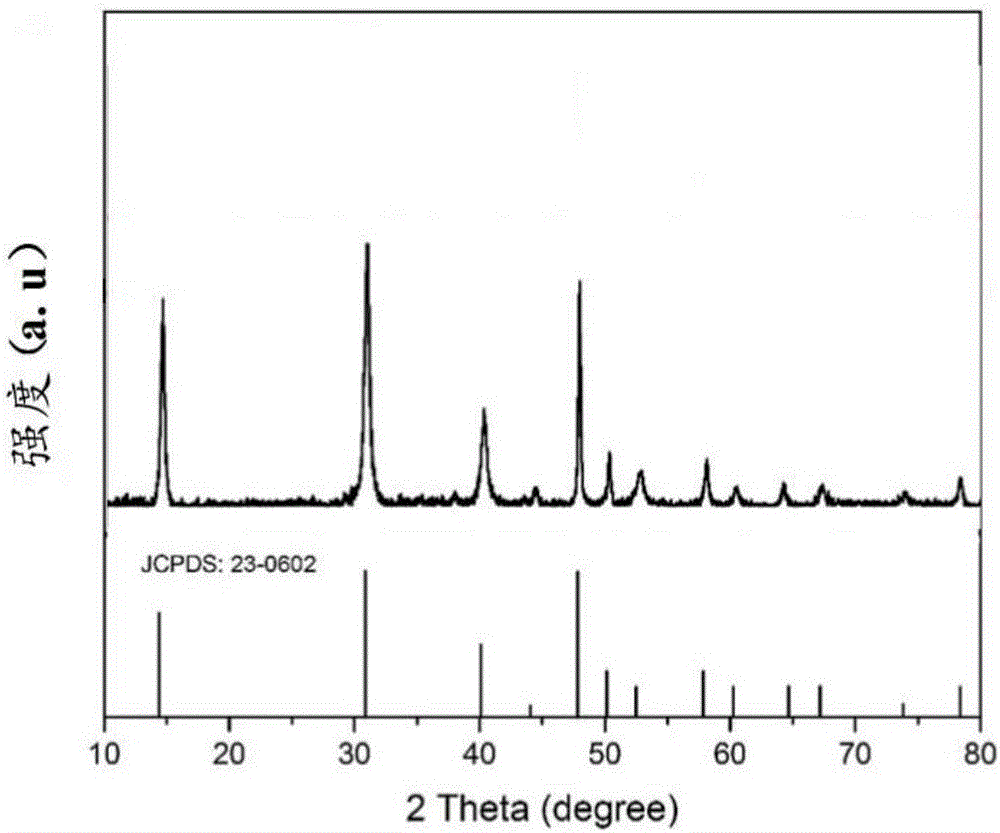

[0040] First, weigh 5 mmol of tin tetrachloride pentahydrate and dissolve it in 50 mL of deionized water and stir for 10 min to dissolve it completely. Take another 50mL of water, pass nitrogen gas for 5min first, then add 20mmol sodium borohydride, stir well, after it is completely dissolved, add 10mmol selenium powder, stir for 30min to make it completely dissolved. Then the above two solutions were mixed, 0.4g of polyethyleneimine with a molecular weight of 1200 was added, stirred for 1 hour, then moved to a reaction kettle, and subjected to a hydrothermal reaction at 200°C for 24 hours, and then the hydrothermal reaction product was suction filtered, After washing and vacuum drying, a tin diselenide / polyethyleneimine composite material is obtained. XRD results show that the tin diselenide material does not have any impurities.

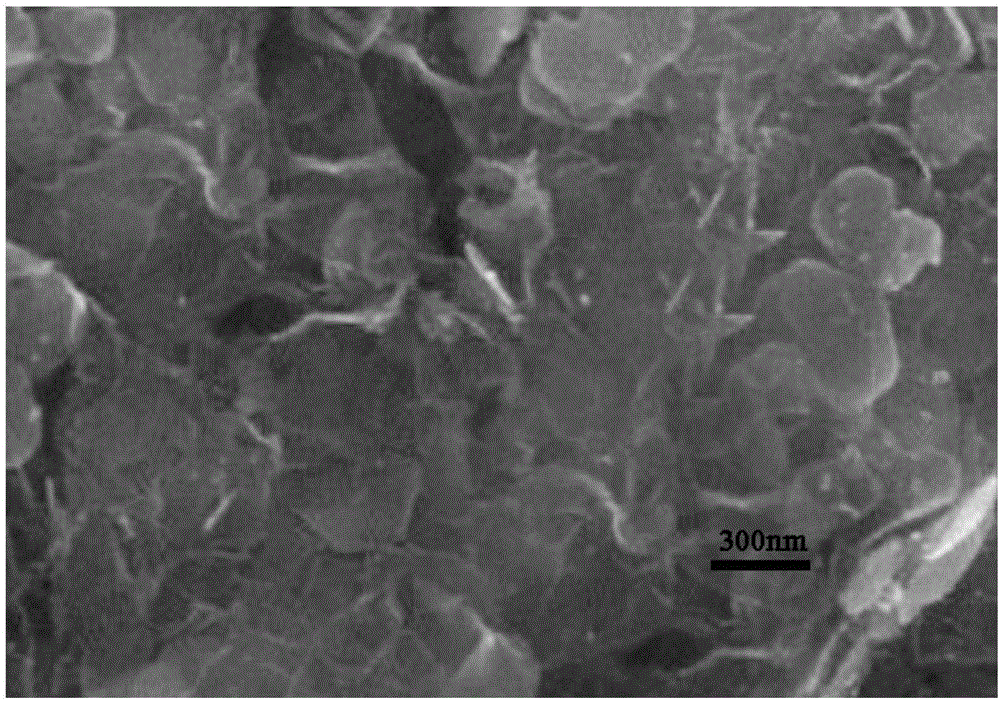

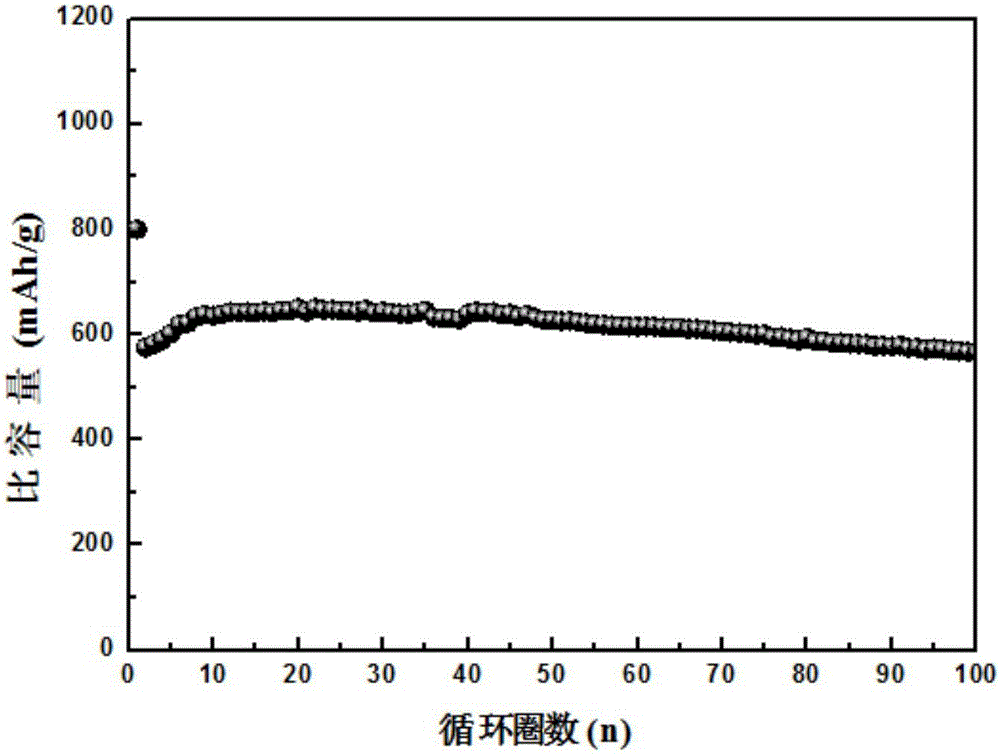

[0041] From figure 2 and image 3 It can be seen that the thickness of the tin diselenide hexagonal nanosheet is about 10 nm, and the side len...

Embodiment 2

[0044]First, weigh 6 mmol of tin tetrachloride pentahydrate and dissolve it in 50 mL of deionized water and stir for 10 min to completely dissolve it. Take another 50mL of water, pass nitrogen gas for 5min first, then add 25mmol sodium borohydride, stir well, after all dissolved, add 12mmol selenium powder, stir for 30min to make it completely dissolved. Then the above two solutions were mixed, 0.4g of polyethyleneimine with a molecular weight of 1200 was added, stirred for 1 hour, then moved to a reaction kettle, and subjected to a hydrothermal reaction at 200°C for 24 hours, and then the hydrothermal reaction product was suction filtered, After washing and vacuum drying, a tin diselenide / polyethyleneimine composite material is obtained. The thickness of the tin diselenide hexagonal nanosheet is about 15nm, and the side length is about 80nm.

[0045] The negative electrode composite material of the sodium ion battery prepared in this example and the sodium sheet are assemble...

Embodiment 3

[0047] First, weigh 6 mmol of tin tetrachloride pentahydrate and dissolve it in 50 mL of deionized water and stir for 10 min to completely dissolve it. Take another 50mL of water, pass nitrogen gas for 5min first, then add 25mmol sodium borohydride, stir well, after all dissolved, add 12mmol selenium powder, stir for 30min to make it completely dissolved. Then the above two solutions were mixed, 0.4 g of polyethyleneimine with a molecular weight of 2000 was added, stirred for 1 hour, then moved to a reaction kettle, and subjected to a hydrothermal reaction at 200°C for 24 hours, and then the hydrothermal reaction product was suction-filtered, After washing and vacuum drying, a tin diselenide / polyethyleneimine composite material is obtained. The thickness of the tin diselenide hexagonal nanosheet is about 14nm, and the side length is about 80nm.

[0048] The negative electrode composite material of the sodium ion battery prepared in this example and the sodium sheet are assemb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com