Generator online testing device and method

An on-line test and generator technology, applied in the direction of motor generator test, measurement device, measurement of electricity, etc., can solve the problem of wasting manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

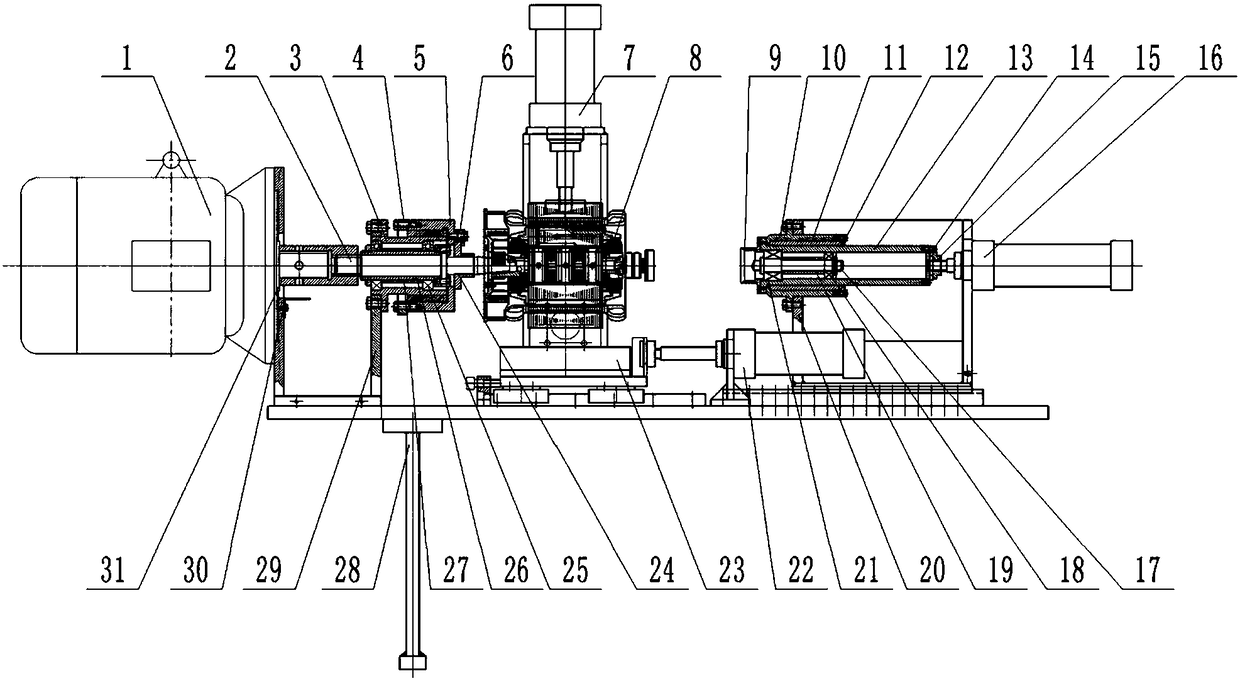

[0035] Embodiment 1 generator online test device

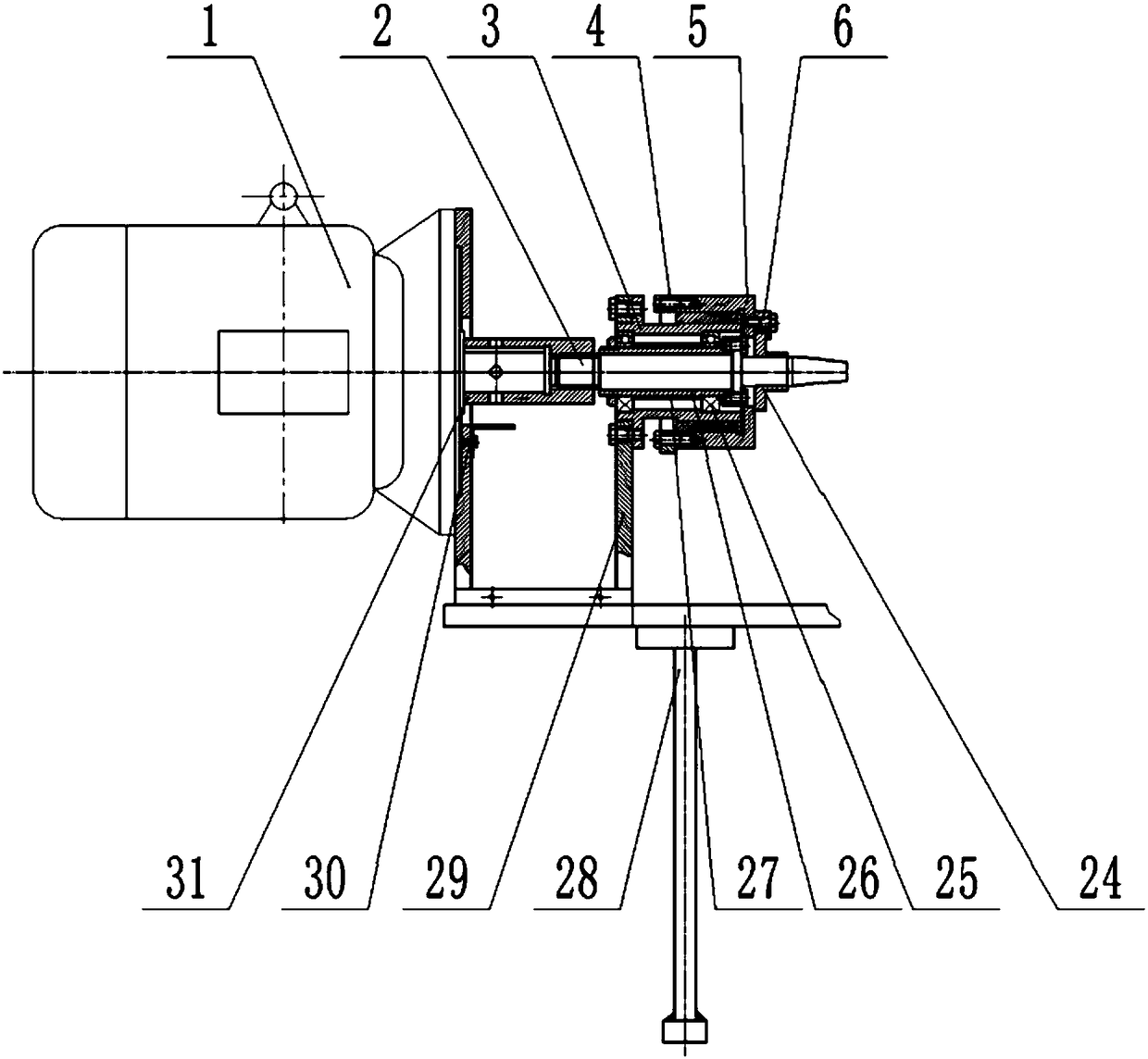

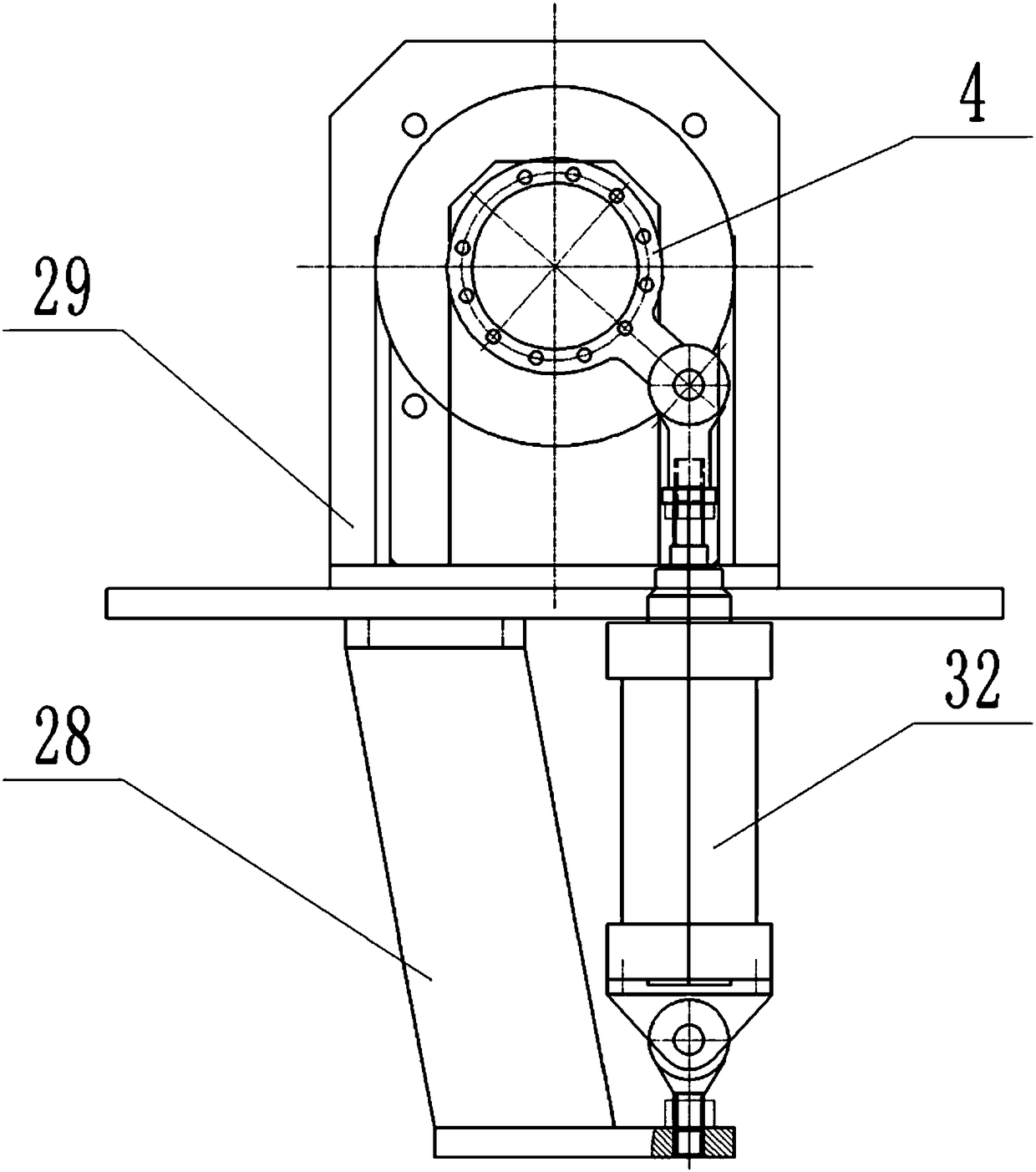

[0036] like Figure 1-6 The generator online test device shown has a power connection mechanism, a rotor tightening mechanism, a stator fixing mechanism and a carbon brush power supply mechanism. Power connection mechanism such as Figure 2-3 As shown, there is a motor base 29 arranged on the test bench, the motor 1 is fixedly installed on the motor base 29, the output shaft of the motor 1 is connected to the drive spindle 2 through the motor spline sleeve 31 for transmission, and a motor 1 is provided below the output shaft Speed sensor support 30, a speed sensor is fixed above the speed sensor support 30, for testing the rotating speed of motor 1;

[0037] The drive spindle 2 is fixedly connected with the drive spindle bearing sleeve 26 by bolts; the left end of the spindle flange seat 3 ( figure 1 and 2shown in the left) is fixed on the motor base 29, the drive spindle bearing sleeve 26 is installed on the spindle fla...

Embodiment 2

[0042] Embodiment 2 generator online test method

[0043] Adopt the generator on-line test device of above-mentioned embodiment 1, start by computer control generator on-line test device;

[0044] Using the stator fixing mechanism, the stator of the generator under test 8 is placed on the V-shaped block 23, and the cylinder I7 drives the Z-axis pressing head to clamp and fix the stator of the generator under test 8 downward.

[0045] Utilize the X, Y axis slide rails, the generator 8 to be tested is brought into the designated position through the cylinder III22 and the cylinder V37, and the X-Y axis position adjustment seat 39 is arranged on the test bench, which is transferred to the designated position in advance.

[0046] Utilize the rotor tightening mechanism, push the tightening slide shaft 13 to the specified position through the cylinder II16, and fix the rotor of the generator 8 to be tested by the joint action of the tightening shaft end cover 9, the tightening trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com