Method for determining chemical oxygen demand of electrolyzed high chlorine waste water

A technology for chemical oxygen demand and high-chlorine wastewater, applied in the field of detection, can solve the problem of low COD results and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

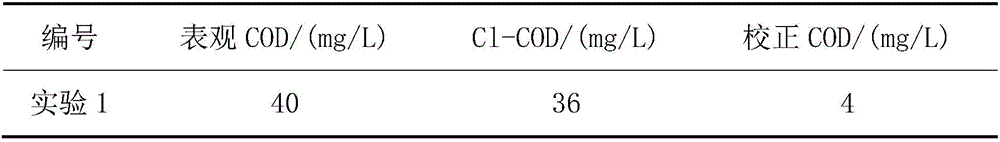

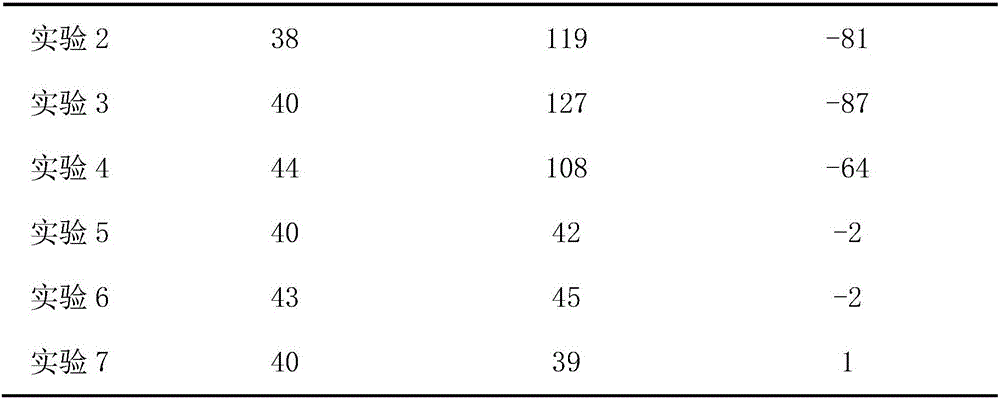

Examples

Embodiment 1

[0017] The method for measuring the chemical oxygen demand of high chlorine wastewater after electrolytic treatment comprises the following steps in turn:

[0018] 1) Take the water sample to be tested or the diluted water sample to be tested into a closed container. Wherein, high-chlorine wastewater refers to wastewater with a chloride ion concentration of 2,000-20,000 mg / L or diluted wastewater. The free residual chlorine contained in the high chlorine wastewater will interfere with the determination of chemical oxygen demand. Free residual chlorine means that the water sample to be tested contains hypochlorous acid, hypochlorite, elemental chlorine gas or a mixture of two or more of the above components.

[0019] 2) Adjust the pH value of the sample to below 3 with concentrated sulfuric acid.

[0020] 3) Aerate the water sample, the aeration flow rate is 1-3L / min, and the aeration time is 0.5-1min / 10ml. That is, the aeration flow rate can be 1, 2 or 3 L / min, and the rela...

Embodiment 2

[0024] In this embodiment, the COD is measured with the effluent A with high chlorine content of an electrolysis process.

[0025] The method for measuring the chemical oxygen demand of high chlorine wastewater after electrolytic treatment comprises the following steps in turn:

[0026] 1) Take 100mL of the water sample to be tested or the diluted water sample to be tested into a closed container.

[0027] 2) Adjust the pH of the sample to below 3 with concentrated sulfuric acid (ρ(H2SO4)=1.84g / mL, the same below).

[0028] 3) Use nitrogen as the gas source, use the aeration sand head to aerate the water sample, the aeration flow rate is 1L / min, the relationship between the aeration time t and the volume L of the water sample to be tested is: t=L×1min / 10ml . At the same time, a vacuum pump is used to evacuate the container to ensure that the pressure in the container is 0.05 MPa.

[0029] 4) If the pH of the water sample returns to above 3 during the aeration process, repea...

Embodiment 3

[0032] In this embodiment, the COD is measured with the effluent A with high chlorine content of an electrolysis process.

[0033] The method for measuring the chemical oxygen demand of high chlorine wastewater after electrolytic treatment comprises the following steps in turn:

[0034] 1) Take 100mL water sample into a closed container.

[0035] 2) Add concentrated sulfuric acid (ρ(H2SO4)=1.84g / mL) dropwise until the pH is less than 3.

[0036] 3) Connect the air pump of the aeration pipe, connect the aeration sand head to the aeration pipe, put the aeration sand head into the water sample, and turn on the power of the air pump to start aeration. The aeration gas is nitrogen, and the flow rate is adjusted at about 2L / min. The relationship between the aeration time t and the volume L of the water sample to be tested is: t=L×0.5min / 10ml. During this process, a vacuum pump is used to evacuate the inside of the container to ensure that the pressure in the container is 0.06 MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com