Experiment device and method for measuring metal wire Young modulus based on simple harmonic vibration

A simple harmonic vibration and Young's modulus technology, applied in the field of university physics experiments, can solve problems such as easy damage, electric shock to the experimenter, single principle, etc., to enhance the problem-solving ability, convenient observation and measurement, and intuitive experimental phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

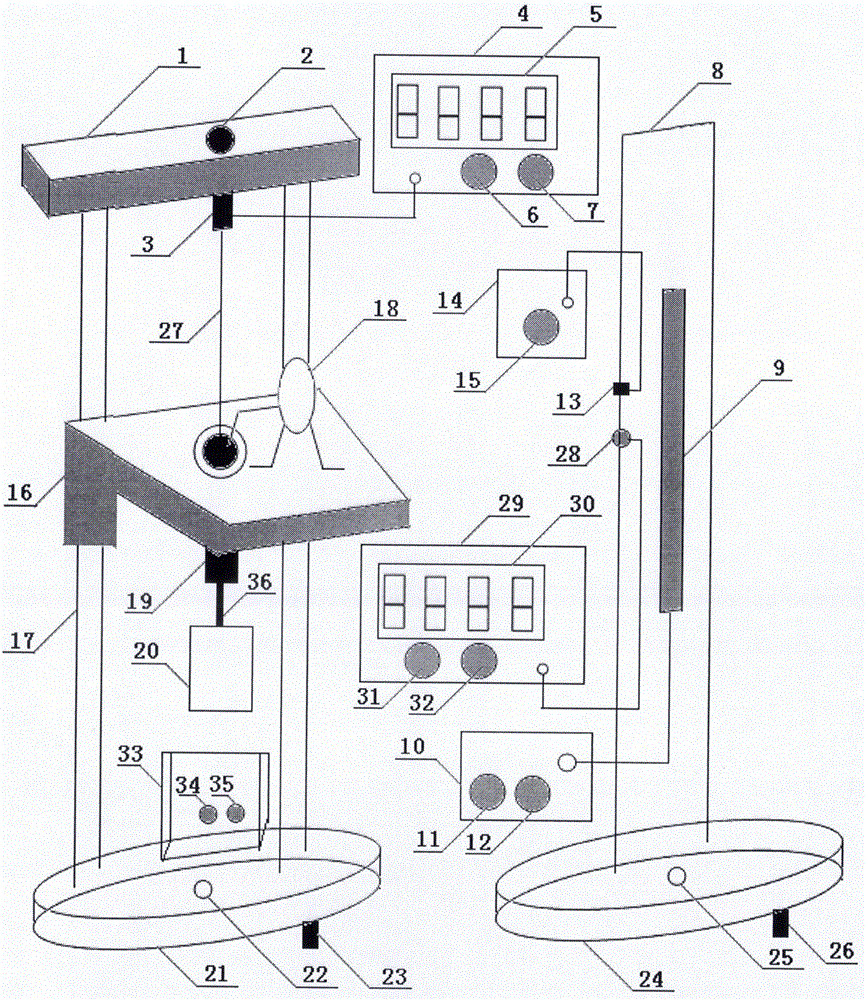

[0044] In the figure, a bracket 17 is set on the bracket base 21, a beam 1 is set on the upper end of the bracket 17, a platform 16 is set in the middle of the bracket 17, and the platform 16 can move along the bracket 17 to change its position. Chuck 2 and force sensitive sensor 3, one end of metal wire 27 is connected with upper chuck 2 and force sensitive sensor 3, the other end passes through the round hole in the middle of platform 16 and is connected with lower chuck 19, and the upper end of lower chuck 19 is connected with platform 16 On the same horizontal plane, the lower chuck 19 is connected to the iron block 20 through the connecting device 36 , and an electromagnet device 33 is arranged below the iron block 20 . The force-sensitive sensor 3 is connected with the force-sensitive sensor measuring controller 4 through an interface, and the force-sensitive sensor 3 is used to measure the tensile force of the metal wire 27 , and can be displayed through the force-sensit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com