Gas-containing coal body expansion deformation measurement method

A measurement method, gas coal technology, applied in the field of coal expansion and deformation measurement, gas-containing coal expansion and deformation measurement, can solve the problems of large impact of mining, large consumption of manpower and material resources, high cost, etc., to achieve simple overall structure and measurement principle The effect of simplicity and few distracting factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

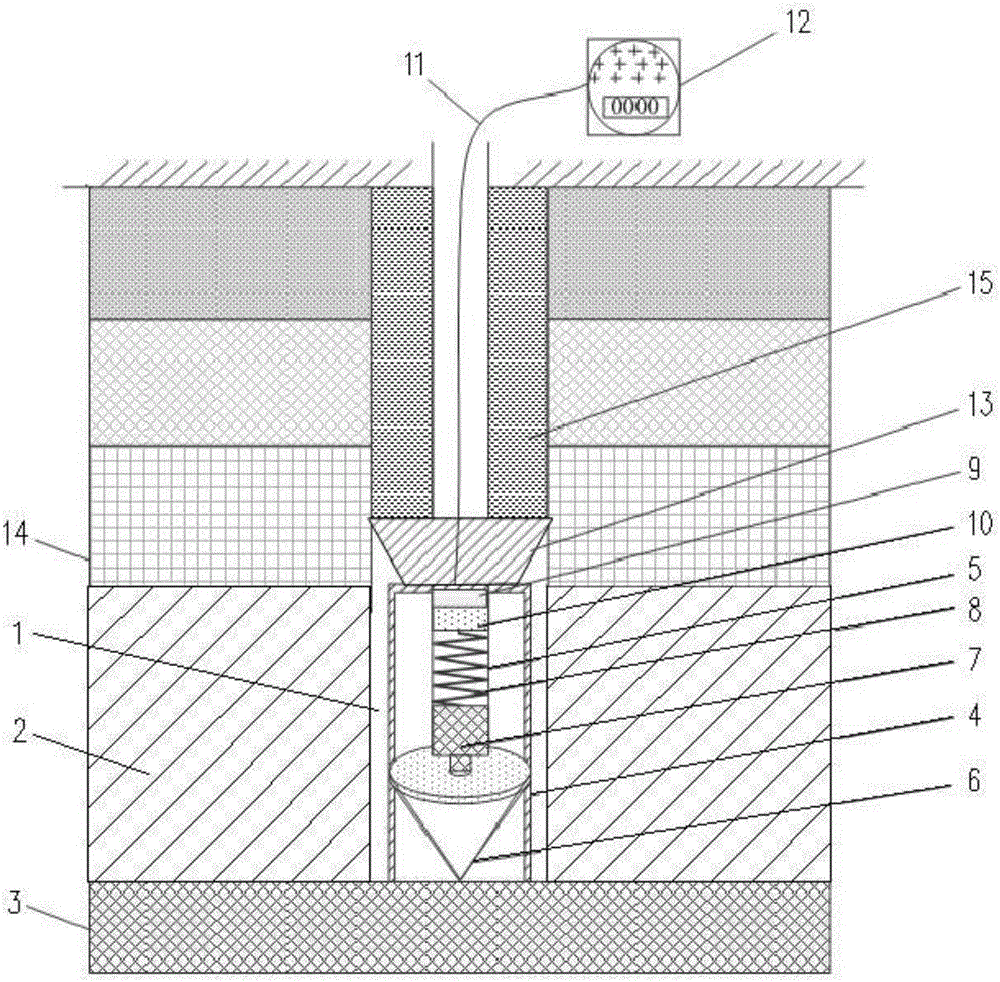

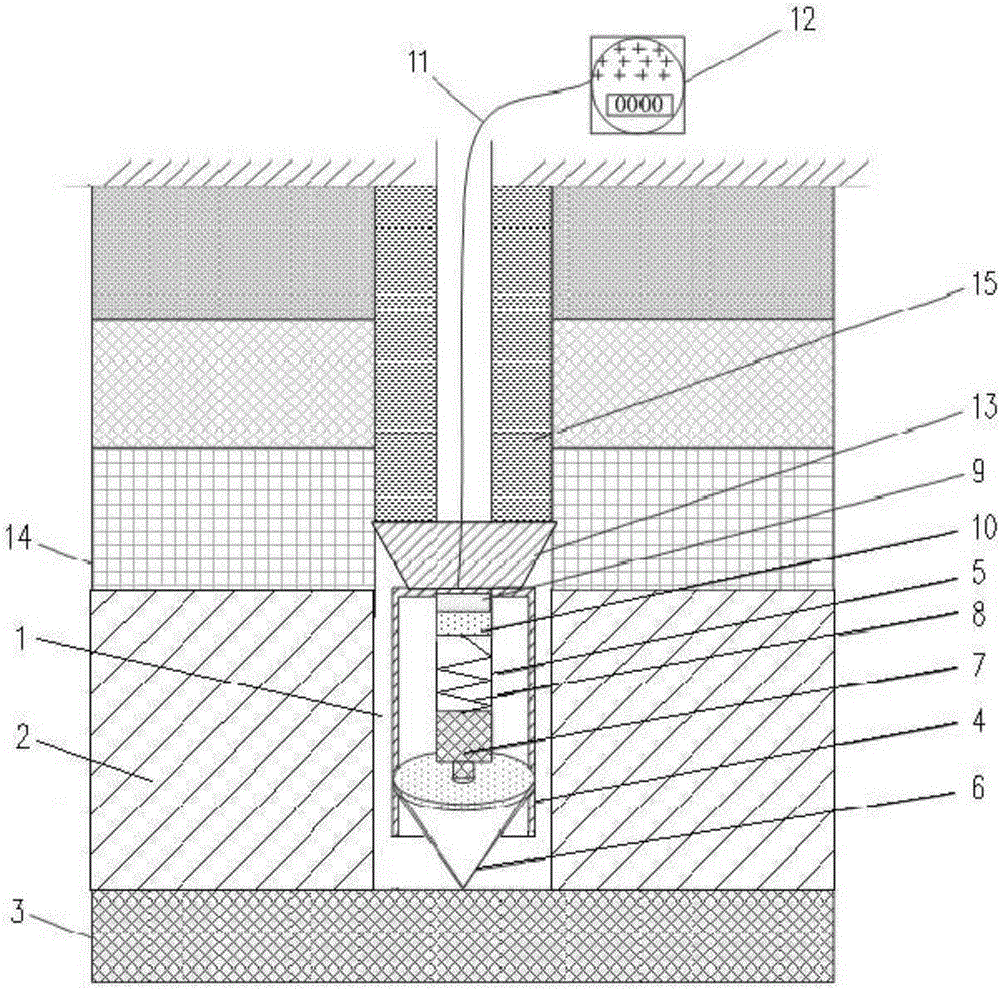

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] The method for measuring expansion and deformation of gas-containing coal body in this embodiment includes the following steps:

[0023] (a) Set up a borehole 1 with an angle greater than 80° between the axis line and the horizontal plane and a borehole diameter of 133mm, and the borehole passes through the coal seam 2 and reaches the bottom plate 3 to stop construction;

[0024] (b) Send the gas-containing coal expansion and deformation measurement device to the bottom of the borehole. The gas-containing coal expansion and deformation measurement device includes a large casing 4, a small casing 5, a weight 6, a slider 7, and a spring 8 , a sensor 9, a fixed end 10, a wire 11 and a digital display stress gauge 12 with a memory storage function arranged outside the borehole;

[0025] The diameter of the large casing is smaller than the diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com