Pipeline leakage detection device and detection method

A leak detection device and leak detection technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as complex signal acquisition and processing, and inconvenient sensor maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

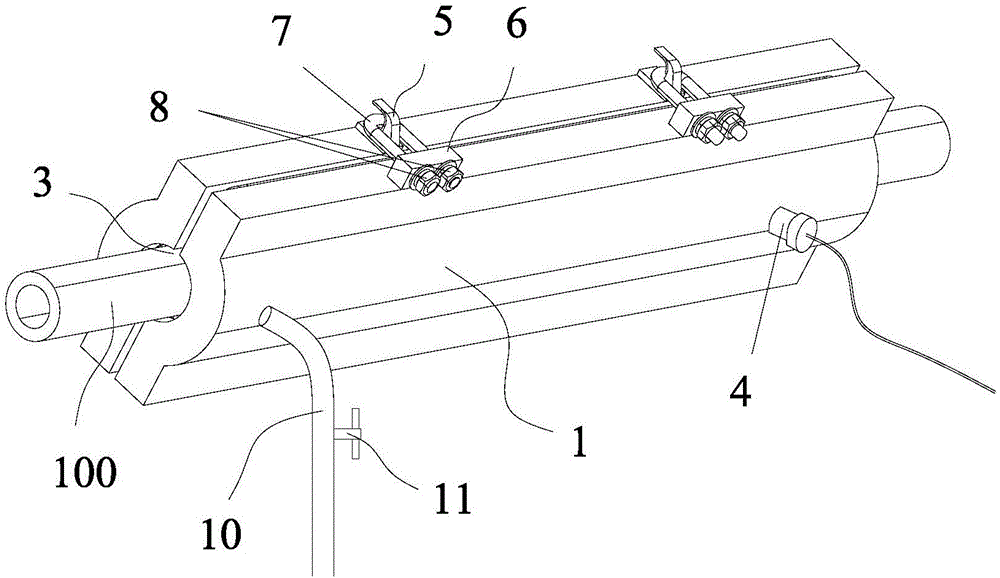

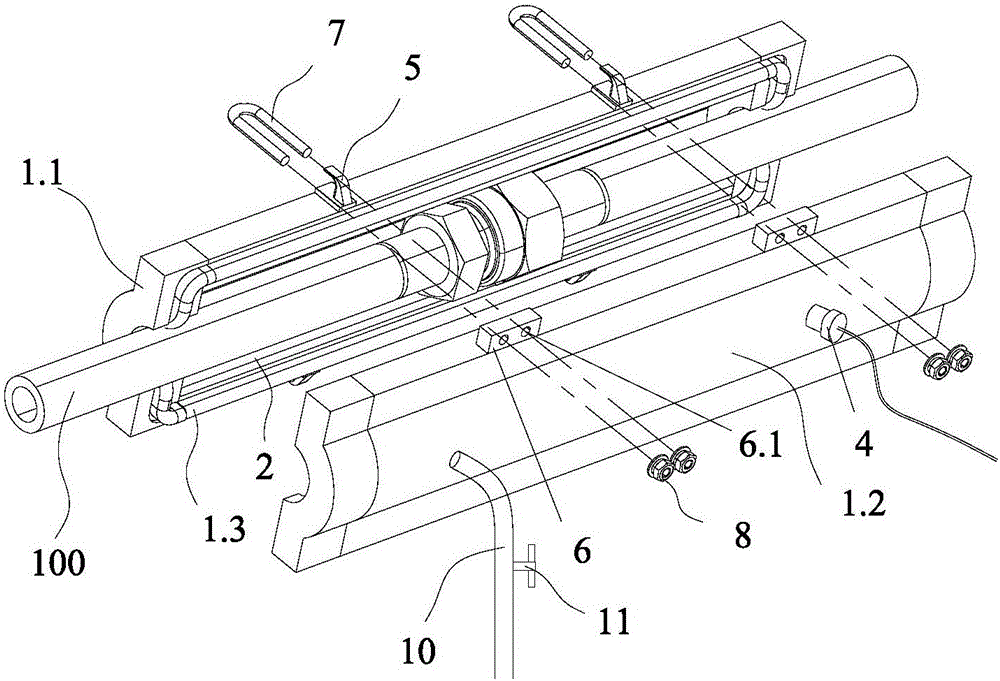

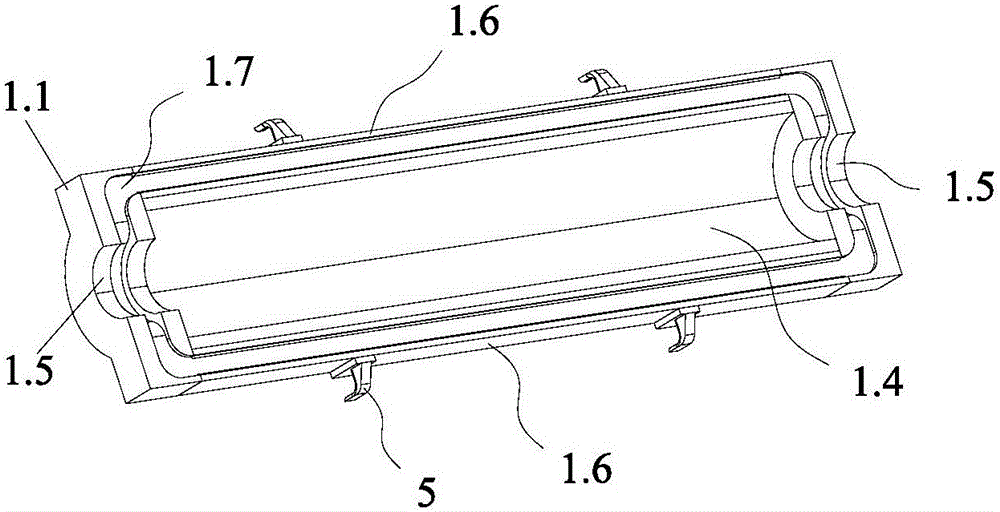

[0038] See attached figure 1 to attach Figure 8 As shown, a pipeline leakage detection device includes an inclusion 1 that wraps the pipeline section 100 to be tested and forms an annular seal; the inclusion 1 extends along the axis of the pipeline section 100 to be tested, and the inclusion 1 There is a space 2 for accommodating gas between the inner wall surface and the outer wall of the pipeline section 100 to be tested; through holes 3 for accommodating the pipeline section 100 to be tested are provided at both ends of the inclusion 1; the inclusion 1 and the pipeline section 100 to be tested are The through hole 3 is a sealed connection; the inclusion 1 is provided with a gas leakage sensing device 4 for monitoring whether the detected pipeline section 100 leaks; the gas leakage sensing device 4 is electrically connected to an external...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com